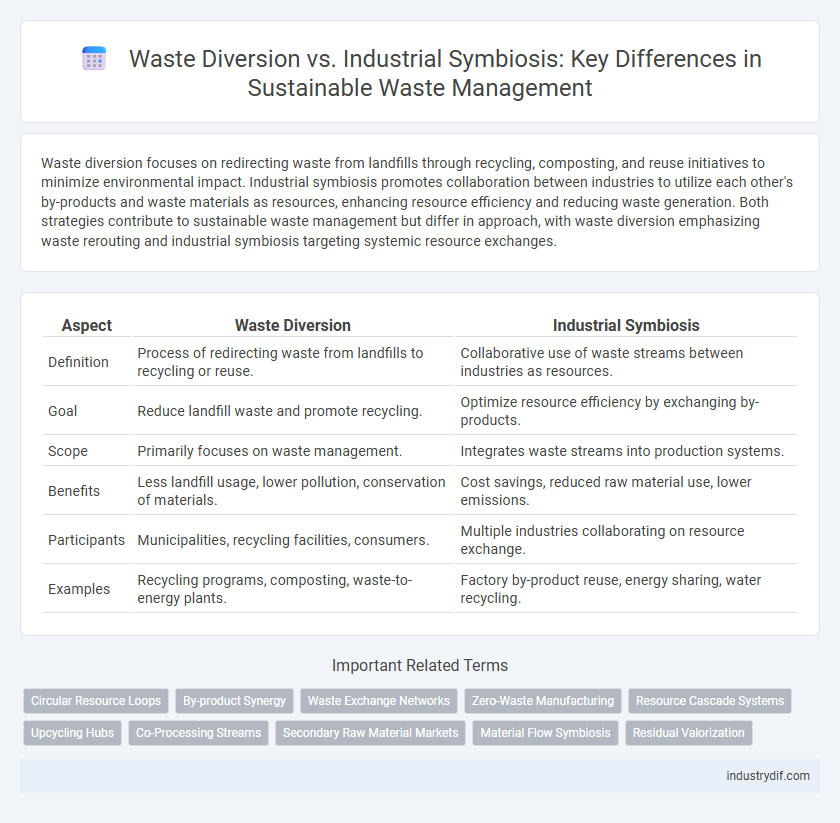

Waste diversion focuses on redirecting waste from landfills through recycling, composting, and reuse initiatives to minimize environmental impact. Industrial symbiosis promotes collaboration between industries to utilize each other's by-products and waste materials as resources, enhancing resource efficiency and reducing waste generation. Both strategies contribute to sustainable waste management but differ in approach, with waste diversion emphasizing waste rerouting and industrial symbiosis targeting systemic resource exchanges.

Table of Comparison

| Aspect | Waste Diversion | Industrial Symbiosis |

|---|---|---|

| Definition | Process of redirecting waste from landfills to recycling or reuse. | Collaborative use of waste streams between industries as resources. |

| Goal | Reduce landfill waste and promote recycling. | Optimize resource efficiency by exchanging by-products. |

| Scope | Primarily focuses on waste management. | Integrates waste streams into production systems. |

| Benefits | Less landfill usage, lower pollution, conservation of materials. | Cost savings, reduced raw material use, lower emissions. |

| Participants | Municipalities, recycling facilities, consumers. | Multiple industries collaborating on resource exchange. |

| Examples | Recycling programs, composting, waste-to-energy plants. | Factory by-product reuse, energy sharing, water recycling. |

Defining Waste Diversion: Concepts and Practices

Waste diversion involves redirecting waste materials away from landfills through recycling, composting, and reuse initiatives, reducing environmental impact and conserving resources. It encompasses community-based programs and industrial processes aimed at minimizing landfill dependency by recovering valuable materials. This practice contrasts with industrial symbiosis, which focuses on the exchange of by-products between industries to optimize resource efficiency and reduce overall waste generation.

Understanding Industrial Symbiosis in Modern Industries

Industrial symbiosis integrates diverse industries to exchange waste materials and by-products, transforming waste streams into valuable resources and significantly reducing landfill disposal. Unlike traditional waste diversion, which primarily focuses on separating and recycling waste, industrial symbiosis emphasizes collaborative resource optimization and circular economy principles in modern industries. This approach enhances sustainability by minimizing raw material consumption and fostering inter-industry partnerships that drive environmental and economic benefits.

Key Differences Between Waste Diversion and Industrial Symbiosis

Waste diversion primarily aims to reduce landfill use by redirecting materials through recycling, composting, or reuse within a single entity or community. Industrial symbiosis involves collaboration between different industries, where waste or by-products from one process serve as raw materials for another, creating a closed-loop system. Key differences include the scope of cooperation, with waste diversion being largely localized and industrial symbiosis operating across multiple organizations, enhancing resource efficiency at a regional or industrial ecosystem level.

Environmental Benefits of Waste Diversion

Waste diversion minimizes landfill use by redirecting materials towards recycling, composting, and reuse, significantly reducing greenhouse gas emissions and soil contamination. This process conserves natural resources and lowers energy consumption associated with extracting and processing raw materials. Enhancing waste diversion efforts directly supports circular economy initiatives and decreases environmental pollution.

Economic Advantages of Industrial Symbiosis

Industrial symbiosis significantly enhances economic advantages by transforming waste streams into valuable inputs for multiple industries, reducing raw material costs and minimizing landfill fees. This collaborative approach fosters resource efficiency, leading to cost savings through shared utilities and byproducts recovery. Companies engaged in industrial symbiosis also benefit from improved supply chain resilience and new revenue opportunities from secondary materials.

Case Studies: Successful Waste Diversion Initiatives

Case studies of successful waste diversion initiatives highlight the strategic separation and recycling of materials to reduce landfill dependence. Industrial symbiosis exemplifies this by linking multiple industries to exchange waste streams as raw materials, significantly minimizing overall waste generation. Examples from regions like Kalundborg, Denmark demonstrate up to 80% reduction in waste through collaborative industrial practices.

Examples of Industrial Symbiosis in Action

Industrial symbiosis exemplifies waste diversion by transforming by-products from one industry into valuable resources for another, reducing landfill use and conserving raw materials. Notable examples include the Kalundborg Symbiosis in Denmark, where energy, steam, and waste materials are exchanged among companies to minimize environmental impact and costs. This closed-loop system demonstrates how collaborative resource sharing can enhance sustainable industrial practices and significantly divert waste from disposal.

Challenges in Implementing Waste Diversion Strategies

Waste diversion strategies face significant challenges including limited infrastructure for effective sorting and processing, inconsistent regulatory frameworks, and a lack of public awareness or participation. Industrial symbiosis requires complex coordination among diverse industries to exchange waste materials as resources, hindered by logistical barriers and trust issues between partners. Both approaches struggle with economic viability in the absence of strong incentives or market demand for secondary materials.

Barriers to Industrial Symbiosis Adoption

Barriers to industrial symbiosis adoption include lack of trust among participating industries, limited information sharing, and regulatory constraints that hinder waste exchange. High initial investment costs and complex coordination requirements further impede collaboration needed for effective resource recovery. Overcoming these challenges requires targeted policy support, enhanced communication platforms, and financial incentives to promote sustainable waste diversion practices.

Future Trends: Integrating Waste Diversion with Industrial Symbiosis

Future trends in waste management emphasize integrating waste diversion strategies with industrial symbiosis to maximize resource efficiency and minimize landfill use. Collaborative networks between industries enable the reuse of by-products and waste streams, promoting circular economy principles. Advanced technologies and data analytics facilitate real-time tracking and optimization of material exchanges, enhancing sustainability outcomes.

Related Important Terms

Circular Resource Loops

Waste diversion emphasizes redirecting materials from landfills through recycling and composting, while industrial symbiosis creates circular resource loops by enabling industries to exchange by-products as raw materials, enhancing sustainability and reducing environmental impact. Industrial symbiosis fosters closed-loop systems that optimize resource efficiency and minimize waste generation, surpassing traditional waste diversion methods in promoting circular economy principles.

By-product Synergy

Waste diversion focuses on redirecting waste streams from landfills through recycling and reuse, while industrial symbiosis leverages by-product synergy by transforming waste materials from one industry into valuable inputs for another. This collaborative resource exchange minimizes environmental impact and enhances circular economy efficiency by optimizing industrial by-products.

Waste Exchange Networks

Waste diversion involves redirecting waste materials from landfills through recycling, composting, or reuse programs, significantly reducing environmental impact and resource consumption. Industrial Symbiosis leverages waste exchange networks to enable multiple industries to collaboratively reuse by-products and waste streams as raw materials, creating closed-loop supply chains that enhance sustainability and economic efficiency.

Zero-Waste Manufacturing

Waste diversion strategies minimize landfill use by redirecting materials through recycling and reuse, while industrial symbiosis fosters resource exchanges between industries to optimize waste as input for new production cycles; zero-waste manufacturing integrates these approaches by designing processes that eliminate waste generation entirely, promoting sustainability and cost-efficiency in industrial ecosystems. Implementing closed-loop systems within zero-waste manufacturing significantly reduces environmental impact, enhances material recovery rates, and drives innovation in resource management.

Resource Cascade Systems

Waste diversion primarily emphasizes rerouting waste from landfills through recycling, composting, and reuse to minimize environmental impact. Industrial symbiosis advances resource cascade systems by facilitating the continuous exchange of by-products and energy between industries, optimizing resource efficiency and drastically reducing waste generation.

Upcycling Hubs

Upcycling hubs serve as crucial nodes in waste diversion by transforming discarded materials into valuable products, effectively reducing landfill inputs and conserving resources. Industrial symbiosis leverages these hubs by facilitating resource exchanges among industries, optimizing material flows, and promoting circular economy practices.

Co-Processing Streams

Waste diversion strategies prioritize redirecting solid waste from landfills through recycling, composting, or energy recovery processes, effectively reducing environmental impact. Industrial symbiosis enhances waste diversion by facilitating the co-processing of waste streams, where by-products from one industry become valuable inputs for another, thereby optimizing resource efficiency and minimizing overall waste generation.

Secondary Raw Material Markets

Waste diversion emphasizes redirecting materials from landfills toward recycling and reuse, creating robust Secondary Raw Material Markets that reduce environmental impact and resource extraction. Industrial symbiosis enhances these markets by fostering collaborative exchanges of by-products between industries, maximizing material recovery and economic value through efficient resource utilization.

Material Flow Symbiosis

Waste diversion strategies aim to reduce landfill inputs by redirecting materials through recycling and reuse, while industrial symbiosis emphasizes material flow symbiosis where waste outputs from one industry serve as input resources for another, enhancing circular economy efficiency. Material flow symbiosis optimizes resource utilization by minimizing waste through interconnected industrial processes, significantly reducing environmental impacts and promoting sustainable production systems.

Residual Valorization

Waste diversion focuses on redirecting residual materials from landfills through recycling and recovery processes, whereas industrial symbiosis emphasizes the exchange of by-products and energy between industries to achieve residual valorization. Industrial symbiosis enhances resource efficiency by transforming waste streams into valuable inputs for adjacent sectors, promoting circular economy principles beyond traditional waste diversion methods.

Waste Diversion vs Industrial Symbiosis Infographic

industrydif.com

industrydif.com