Material Recovery Facilities (MRFs) rely on manual and mechanical processes to separate recyclable materials, whereas Robotic Sorting Facilities use advanced AI-driven robots for higher precision and efficiency in waste sorting. Robotic systems reduce contamination rates and improve throughput by rapidly identifying and sorting diverse materials with minimal human intervention. This technology enhances resource recovery, lowers operational costs, and supports sustainable waste management practices.

Table of Comparison

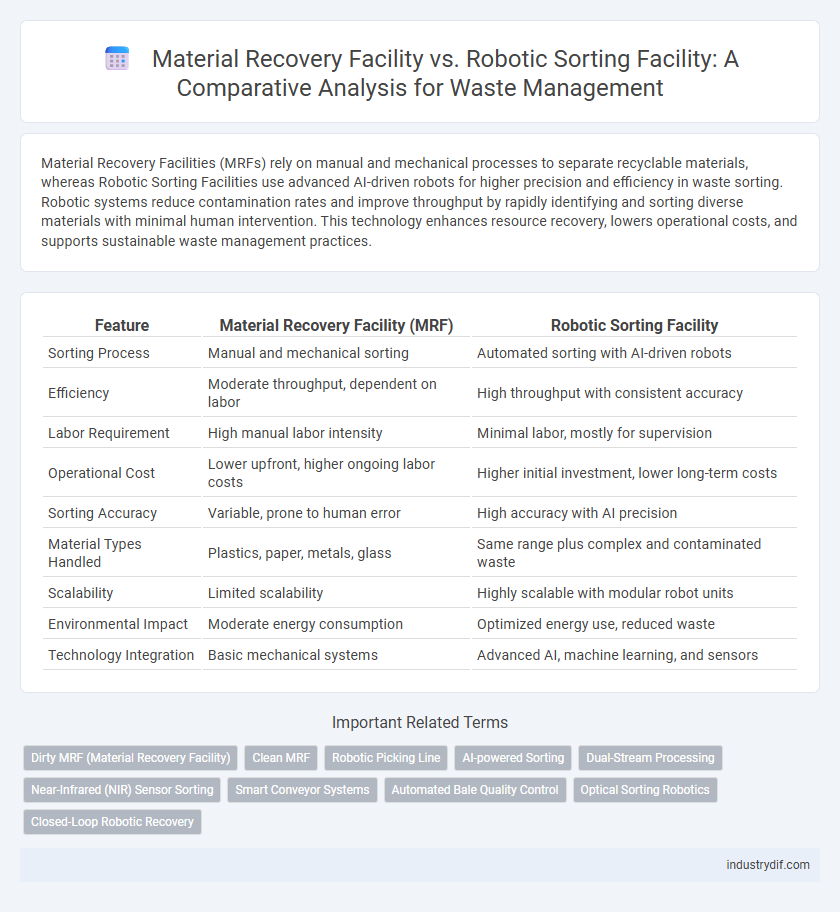

| Feature | Material Recovery Facility (MRF) | Robotic Sorting Facility |

|---|---|---|

| Sorting Process | Manual and mechanical sorting | Automated sorting with AI-driven robots |

| Efficiency | Moderate throughput, dependent on labor | High throughput with consistent accuracy |

| Labor Requirement | High manual labor intensity | Minimal labor, mostly for supervision |

| Operational Cost | Lower upfront, higher ongoing labor costs | Higher initial investment, lower long-term costs |

| Sorting Accuracy | Variable, prone to human error | High accuracy with AI precision |

| Material Types Handled | Plastics, paper, metals, glass | Same range plus complex and contaminated waste |

| Scalability | Limited scalability | Highly scalable with modular robot units |

| Environmental Impact | Moderate energy consumption | Optimized energy use, reduced waste |

| Technology Integration | Basic mechanical systems | Advanced AI, machine learning, and sensors |

Introduction to Material Recovery and Robotic Sorting Facilities

Material Recovery Facilities (MRFs) efficiently sort mixed recyclables using manual and automated processes to separate materials like paper, plastics, and metals for recycling. Robotic Sorting Facilities utilize advanced AI-driven robotic arms equipped with sensors and machine learning algorithms to identify and segregate waste materials at higher speed and accuracy. Both systems aim to enhance recycling rates by improving the purity and quality of sorted materials, reducing contamination, and optimizing waste stream management.

Defining Material Recovery Facility (MRF)

A Material Recovery Facility (MRF) is a specialized plant where mixed recyclable materials are sorted, processed, and prepared for manufacturing reuse, significantly reducing landfill waste. MRFs utilize manual labor combined with mechanical equipment such as conveyor belts, magnets, and screens to separate metals, plastics, paper, and glass effectively. In contrast to robotic sorting facilities, traditional MRFs emphasize human oversight in quality control and adaptability to varying waste streams.

Defining Robotic Sorting Facility

A Robotic Sorting Facility uses advanced AI-powered robots and sensors to identify, separate, and sort recyclable materials with greater precision and speed compared to traditional Material Recovery Facilities (MRFs). These facilities enhance recovery rates by minimizing contamination and enabling the processing of diverse waste streams such as plastics, metals, and paper. The integration of machine learning algorithms allows robotic systems to continuously improve sorting accuracy, leading to more efficient resource recovery and reduced landfill waste.

Key Differences between MRFs and Robotic Sorting Facilities

Material Recovery Facilities (MRFs) rely on manual labor and mechanical systems to sort recyclables, whereas Robotic Sorting Facilities utilize advanced AI-driven robots for higher precision and efficiency. Robotic systems improve sorting speed, reduce contamination rates, and enhance worker safety compared to traditional MRF processes. Cost analysis shows higher initial investment for robotic sorting but greater long-term savings through automation and reduced labor expenses.

Waste Sorting Technology: Manual vs Automated Approaches

Material Recovery Facilities (MRFs) rely heavily on manual sorting techniques combined with basic mechanical systems to separate recyclables, which can lead to lower efficiency and higher contamination rates. In contrast, Robotic Sorting Facilities employ advanced AI-driven robotic arms equipped with sensors and machine learning algorithms, enabling faster and more precise identification and segregation of waste materials. Automated approaches significantly reduce human error and operational costs, enhancing throughput capacity and material purity in waste management processes.

Efficiency and Accuracy in Waste Separation

Material Recovery Facilities (MRFs) achieve waste separation through manual and mechanical processes, providing moderate efficiency and accuracy but often facing challenges with contamination and slower sorting speeds. Robotic Sorting Facilities utilize advanced AI-powered robots and sensors, significantly enhancing sorting accuracy by rapidly identifying and separating materials with minimal human intervention. This technology improves operational efficiency, reduces labor costs, and maximizes material recovery rates compared to traditional MRFs.

Environmental Impact: Comparing Recovery Rates

Material Recovery Facilities (MRFs) typically achieve recovery rates of 70-85% by manually sorting recyclables, while Robotic Sorting Facilities leverage AI and machine learning to exceed 90% recovery efficiency. The enhanced precision in robotic sorting reduces contamination in recycled streams, leading to higher-quality material output and decreased landfill waste. Improved recovery rates directly contribute to lower greenhouse gas emissions by conserving energy and raw materials during recycling processes.

Economic Considerations and Operational Costs

Material Recovery Facilities (MRFs) typically have lower initial capital expenses but higher ongoing labor and maintenance costs compared to Robotic Sorting Facilities, which require significant upfront investment in advanced automation technology yet benefit from reduced labor expenses and improved sorting efficiency. The operational cost savings in robotic facilities stem from precision in material separation, leading to higher resale value of recovered materials and less contamination. Over time, robotic sorting systems offer better scalability and resilience to fluctuating labor availability, making them economically advantageous despite higher initial costs.

Labor and Workforce Implications

Material Recovery Facilities (MRFs) depend heavily on manual labor for sorting recyclable materials, requiring a substantial workforce trained in identifying various items, which can lead to labor-intensive operations and higher labor costs. Robotic Sorting Facilities utilize advanced AI-driven machines to automate the sorting process, reducing the need for human workers and minimizing repetitive strain injuries while increasing sorting accuracy and efficiency. Transitioning to robotic systems shifts workforce demands toward technical maintenance and supervision roles, emphasizing the need for skilled technicians over traditional sorting labor.

Future Trends in Waste Management Facilities

Material Recovery Facilities (MRFs) are evolving with advanced sensor technologies and AI-driven optical sorters to enhance the efficiency of recyclable material separation. Robotic Sorting Facilities increasingly utilize machine learning and robotic arms equipped with hyperspectral imaging, enabling precise identification and extraction of complex waste streams. Future trends in waste management emphasize automation, real-time data analytics, and integration with circular economy principles, driving higher recovery rates and reduced landfill reliance.

Related Important Terms

Dirty MRF (Material Recovery Facility)

A Dirty Material Recovery Facility (Dirty MRF) processes mixed, unsorted waste streams to extract recyclable materials, often resulting in higher contamination rates compared to Robotic Sorting Facilities, which utilize advanced AI-driven robots to identify and separate recyclables more precisely and efficiently. The increased automation in Robotic Sorting Facilities reduces manual labor costs and enhances material purity, leading to higher recovery rates and improved downstream recycling processes.

Clean MRF

Clean Material Recovery Facilities (MRFs) specialize in processing pre-sorted recyclables, resulting in higher purity materials that enhance market value and reduce contamination rates. Robotic sorting facilities utilize advanced AI and machine learning technologies to improve accuracy and efficiency in separating recyclables, offering scalable solutions especially effective in Clean MRF operations.

Robotic Picking Line

Robotic picking lines in waste management utilize advanced AI-driven robotic arms equipped with sensors and machine learning algorithms to identify and sort recyclables with higher precision and speed compared to traditional Material Recovery Facilities (MRFs). These systems significantly enhance recovery rates, reduce contamination, and lower operational costs by automating complex sorting tasks that are typically labor-intensive in conventional MRFs.

AI-powered Sorting

AI-powered sorting in Material Recovery Facilities (MRFs) enhances accuracy by combining human oversight with machine learning algorithms, while Robotic Sorting Facilities rely primarily on autonomous robots equipped with advanced sensors and AI to identify and segregate recyclables with higher precision and efficiency. Robotic systems reduce contamination rates and operational costs by automating tasks traditionally performed by manual labor, accelerating the processing of mixed waste streams and improving recovery rates of valuable materials.

Dual-Stream Processing

Dual-Stream Processing at Material Recovery Facilities (MRFs) separates recyclables into two distinct streams, typically paper/cardboard and containers, enhancing sorting efficiency and material purity. In contrast, Robotic Sorting Facilities employ AI-driven robots capable of handling mixed waste streams, improving flexibility and accuracy but often requiring advanced sensor technologies to optimize dual-stream segregation.

Near-Infrared (NIR) Sensor Sorting

Material Recovery Facilities (MRFs) employing Near-Infrared (NIR) sensor sorting technology achieve high-precision separation of plastics and fibers by detecting specific wavelengths reflected from materials, enhancing recycling accuracy. Robotic Sorting Facilities integrate NIR sensors with AI-driven robotic arms, enabling faster, more flexible sorting of complex waste streams and reducing contamination rates compared to traditional MRFs.

Smart Conveyor Systems

Smart conveyor systems in Material Recovery Facilities (MRFs) enhance manual sorting efficiency, while in Robotic Sorting Facilities, they enable precise item positioning for robotic arms, increasing overall throughput and accuracy. Integration of sensors and AI-driven controls in these smart conveyors optimizes waste stream sorting by real-time identification and segregation of recyclables.

Automated Bale Quality Control

Automated bale quality control in Material Recovery Facilities (MRFs) relies on manual inspections and basic sensor technology, often leading to inconsistencies in sorting accuracy and contamination levels. In contrast, Robotic Sorting Facilities utilize advanced AI-driven vision systems and robotic arms to enhance bale purity and streamline quality control processes, significantly reducing human error and increasing material recovery rates.

Optical Sorting Robotics

Optical sorting robotics in Material Recovery Facilities (MRFs) enhance efficiency by using advanced sensors and AI algorithms to identify and separate recyclables with high precision, significantly reducing contamination rates. Robotic sorting facilities leverage machine learning and vision systems to automate complex waste identification tasks, increasing throughput and accuracy compared to traditional manual sorting processes.

Closed-Loop Robotic Recovery

Closed-Loop Robotic Recovery in Robotic Sorting Facilities enhances material recovery rates by using AI-driven robots to identify and segregate recyclables with precision, reducing contamination and increasing efficiency compared to traditional Material Recovery Facilities (MRFs). This advanced automation supports sustainable waste management by enabling higher purity outputs, facilitating more effective recycling processes and closing the loop in circular economies.

Material Recovery Facility vs Robotic Sorting Facility Infographic

industrydif.com

industrydif.com