Material Recovery Facilities (MRFs) specialize in sorting and processing recyclables from household and commercial waste streams to prepare materials for reuse or resale, optimizing the efficiency of traditional recycling systems. Urban mining involves extracting valuable metals and materials from electronic waste and other discarded products within urban environments, tapping into secondary resource reservoirs to reduce reliance on virgin raw materials. Both approaches play crucial roles in sustainable waste management by enhancing resource recovery and minimizing landfill dependency.

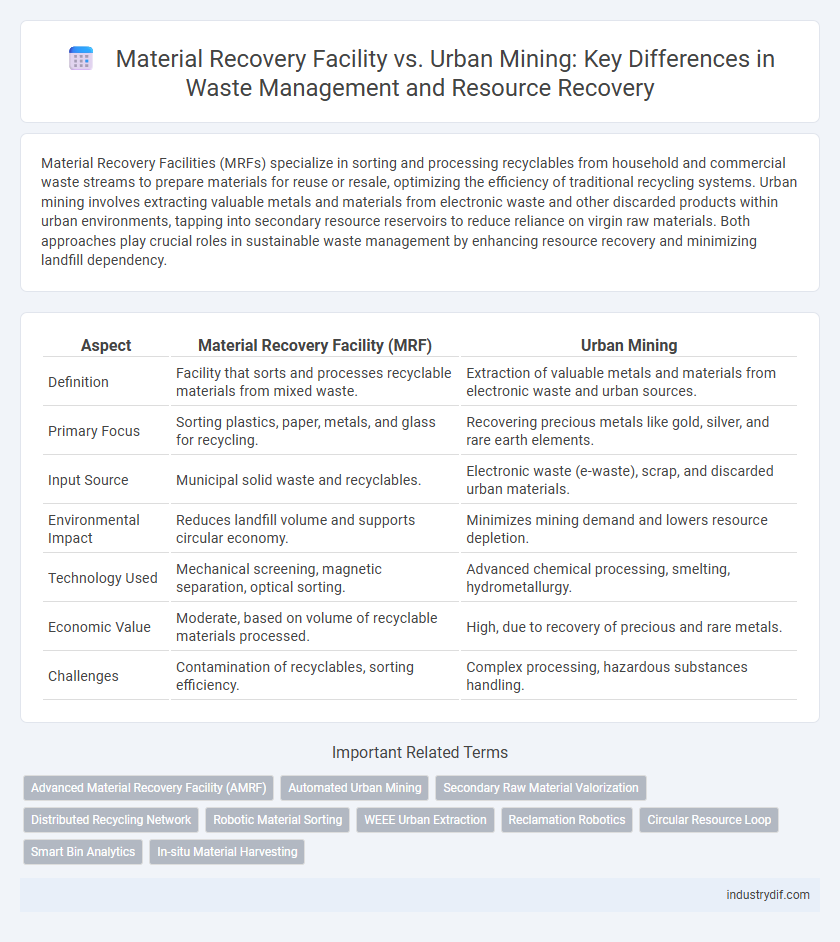

Table of Comparison

| Aspect | Material Recovery Facility (MRF) | Urban Mining |

|---|---|---|

| Definition | Facility that sorts and processes recyclable materials from mixed waste. | Extraction of valuable metals and materials from electronic waste and urban sources. |

| Primary Focus | Sorting plastics, paper, metals, and glass for recycling. | Recovering precious metals like gold, silver, and rare earth elements. |

| Input Source | Municipal solid waste and recyclables. | Electronic waste (e-waste), scrap, and discarded urban materials. |

| Environmental Impact | Reduces landfill volume and supports circular economy. | Minimizes mining demand and lowers resource depletion. |

| Technology Used | Mechanical screening, magnetic separation, optical sorting. | Advanced chemical processing, smelting, hydrometallurgy. |

| Economic Value | Moderate, based on volume of recyclable materials processed. | High, due to recovery of precious and rare metals. |

| Challenges | Contamination of recyclables, sorting efficiency. | Complex processing, hazardous substances handling. |

Introduction to Material Recovery Facility (MRF) and Urban Mining

Material Recovery Facilities (MRFs) are specialized plants where recyclable materials are sorted, cleaned, and processed to recover valuable resources from municipal solid waste streams, improving recycling efficiency and reducing landfill use. Urban mining extracts precious metals and rare earth elements from electronic waste and other discarded urban materials, tapping into the embodied resource wealth of cities while minimizing environmental impact from traditional mining. Both MRFs and urban mining are critical components of the circular economy, enhancing resource recovery and promoting sustainable waste management practices.

Key Differences Between MRF and Urban Mining

Material Recovery Facilities (MRFs) primarily focus on sorting and processing recyclables from mixed waste streams to recover valuable materials like plastics, metals, and paper. Urban Mining involves extracting raw materials from electronic waste, building materials, and other urban sources, emphasizing resource recovery beyond traditional recycling. Unlike MRFs, Urban Mining targets complex waste streams with higher value materials through advanced technologies such as hydrometallurgical and pyrometallurgical processes.

Processes Involved in Material Recovery Facilities

Material Recovery Facilities (MRFs) employ advanced sorting technologies such as conveyor belts, magnetic separators, and optical scanners to efficiently separate recyclable materials like plastics, metals, paper, and glass. These facilities emphasize mechanical and manual processes to remove contaminants, ensuring higher quality output streams for recycling industries. Urban mining, by contrast, focuses on extracting valuable metals and materials from electronic waste and end-of-life products, often involving chemical and metallurgical processes beyond the primary sorting methods used in MRFs.

Urban Mining: Concept and Methodologies

Urban mining involves extracting valuable metals and materials from electronic waste and other discarded products within urban environments, reducing the need for conventional mining. Methodologies include advanced sorting technologies, chemical treatments, and mechanical processes to recover precious metals such as gold, silver, and rare earth elements. This sustainable approach minimizes environmental impact and supports circular economy principles by transforming urban waste into reusable resources.

Economic Benefits of Material Recovery Facilities

Material Recovery Facilities (MRFs) significantly enhance economic benefits by efficiently sorting and processing recyclable materials, reducing landfill costs, and generating revenue through the sale of recovered commodities like metals, plastics, and paper. MRFs create jobs in sorting, maintenance, and logistics, contributing to local economies and promoting sustainable waste management practices. Compared to urban mining, MRFs offer immediate economic returns through the continuous supply of recyclables supporting manufacturing industries.

Environmental Impact of Urban Mining

Urban mining significantly reduces environmental impact by extracting valuable metals from electronic waste, minimizing the need for virgin resource extraction and decreasing landfill volume. Unlike traditional material recovery facilities (MRFs), which primarily sort and recycle common household recyclables, urban mining targets precious metals embedded in e-waste, leading to higher resource efficiency. This process lowers greenhouse gas emissions and conserves natural resources, making it a crucial strategy for sustainable waste management and circular economy development.

Resource Efficiency: MRF vs Urban Mining

Material Recovery Facilities (MRFs) optimize resource efficiency by sorting and processing mixed waste streams into recyclable materials, reducing landfill use and enabling circular economy practices. Urban mining extracts valuable metals and rare earth elements from electronic waste and discarded products, recovering high-value resources with minimal environmental impact compared to traditional mining. Both methods enhance resource efficiency, but urban mining targets scarce and precious materials critical for technology and reduces dependency on virgin resource extraction.

Technological Advancements in Waste Recovery

Material Recovery Facilities (MRFs) utilize advanced sorting technologies such as optical scanners, air classifiers, and robotic arms to efficiently separate recyclables from mixed waste streams, enhancing the purity and quality of recovered materials. Urban mining employs innovative techniques including hydrometallurgical and bioleaching processes to extract valuable metals from electronic waste, enabling the recovery of critical resources like rare earth elements that traditional recycling overlooks. Both approaches leverage cutting-edge technologies to maximize resource recovery, reduce landfill dependence, and support sustainable circular economy practices.

Challenges and Limitations of Both Approaches

Material Recovery Facilities face challenges such as high contamination rates, sorting inefficiencies, and significant energy consumption, limiting the quality and quantity of recyclables recovered. Urban mining struggles with the complexity of extracting valuable metals from mixed waste streams, high processing costs, and the need for advanced technologies to efficiently recover rare materials. Both approaches are constrained by economic viability, regulatory hurdles, and the scalability required to meet growing waste management demands.

Future Prospects for Sustainable Waste Management

Material Recovery Facilities (MRFs) enhance urban mining by efficiently sorting and processing recyclable materials, reducing landfill dependency and conserving natural resources. Urban mining leverages advanced technologies to extract valuable metals and materials from electronic waste and industrial residues, aligning with circular economy principles. Integrating MRFs with urban mining practices promises scalable, sustainable waste management solutions that support resource recovery and minimize environmental impact.

Related Important Terms

Advanced Material Recovery Facility (AMRF)

Advanced Material Recovery Facilities (AMRFs) utilize cutting-edge sorting technologies such as AI-driven robotics and sensor-based systems to enhance the efficiency and purity of recovered materials compared to traditional Material Recovery Facilities (MRFs). Urban mining complements AMRFs by extracting valuable metals and rare earth elements from electronic waste, creating a sustainable circular economy by reducing reliance on virgin raw materials.

Automated Urban Mining

Automated Urban Mining leverages advanced robotics and AI technologies to efficiently extract valuable materials from electronic waste, surpassing the manual processes typically utilized in traditional Material Recovery Facilities (MRFs). This innovation enhances material recovery rates, reduces human exposure to hazardous substances, and optimizes resource circularity by systematically dismantling complex urban waste streams.

Secondary Raw Material Valorization

Material Recovery Facilities (MRFs) enhance secondary raw material valorization by sorting and processing recyclables into high-quality outputs for industrial reuse, while urban mining exploits existing urban waste streams and discarded products to recover valuable metals and materials often overlooked in conventional waste management. Both approaches increase resource efficiency and reduce reliance on virgin materials, promoting sustainable circular economy practices.

Distributed Recycling Network

Material Recovery Facilities (MRFs) centralize waste sorting to extract recyclables, while Urban Mining leverages Distributed Recycling Networks to decentralize material recovery, enabling localized processing and reducing transportation emissions. This networked approach enhances resource efficiency by tapping into urban waste streams, promoting circular economy principles through neighborhood-scale recycling hubs.

Robotic Material Sorting

Robotic material sorting in Material Recovery Facilities (MRFs) uses advanced AI and sensor technologies to efficiently separate recyclables, enhancing processing speed and reducing contamination rates. Urban mining employs similar robotic systems to extract valuable metals and materials from electronic waste and discarded products, maximizing resource recovery and supporting circular economy goals.

WEEE Urban Extraction

Material Recovery Facilities (MRFs) primarily sort and process electronic waste (WEEE) to extract recyclable components, whereas Urban Mining targets the recovery of valuable metals like gold, silver, and palladium directly from discarded electronic devices. Urban Mining leverages advanced extraction technologies to maximize metal yield and reduce environmental impact compared to conventional MRF processes focused on bulk material separation.

Reclamation Robotics

Reclamation Robotics leverages advanced automation and AI-driven sorting technologies to enhance material recovery facility (MRF) efficiency by accurately separating recyclables from mixed waste streams. Urban mining utilizes these robotics to extract valuable metals and components from electronic waste, transforming discarded products into high-purity raw materials for circular economy applications.

Circular Resource Loop

Material Recovery Facilities (MRFs) efficiently sort and process recyclable materials from urban waste streams, enabling the reintegration of recovered resources into manufacturing cycles and reducing landfill reliance. Urban mining complements this by extracting valuable metals and rare elements from electronic waste and discarded products, closing the circular resource loop through sustainable resource reclamation and minimizing virgin material extraction.

Smart Bin Analytics

Material Recovery Facilities (MRFs) use Smart Bin Analytics to enhance the sorting and processing of recyclables by integrating real-time data on waste composition and bin fill levels, improving operational efficiency. Urban Mining leverages Smart Bin Analytics to identify valuable materials within urban waste streams, enabling targeted recovery that reduces landfill reliance and supports sustainable resource management.

In-situ Material Harvesting

Material Recovery Facilities (MRFs) centralize sorting and processing of recyclable materials, while Urban Mining emphasizes in-situ material harvesting by extracting valuable metals and components directly from existing urban infrastructure, significantly reducing the need for raw material extraction. Urban Mining leverages advanced technologies like robotics and sensor-based sorting to maximize resource recovery on-site, enhancing sustainability and circular economy outcomes compared to traditional MRF approaches.

Material Recovery Facility vs Urban Mining Infographic

industrydif.com

industrydif.com