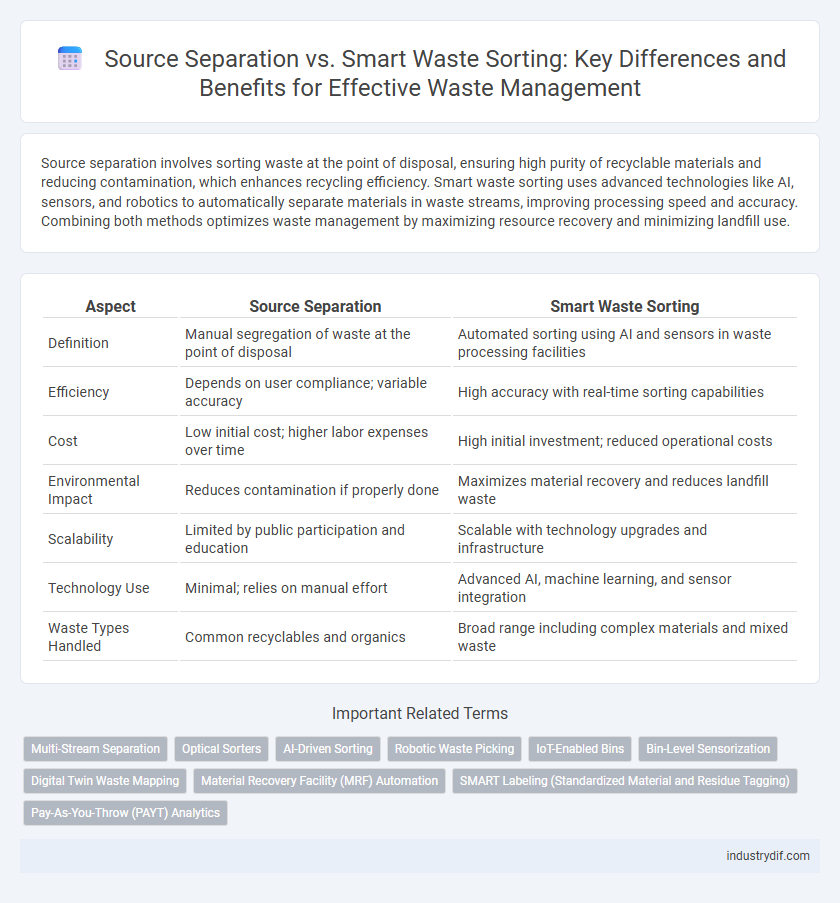

Source separation involves sorting waste at the point of disposal, ensuring high purity of recyclable materials and reducing contamination, which enhances recycling efficiency. Smart waste sorting uses advanced technologies like AI, sensors, and robotics to automatically separate materials in waste streams, improving processing speed and accuracy. Combining both methods optimizes waste management by maximizing resource recovery and minimizing landfill use.

Table of Comparison

| Aspect | Source Separation | Smart Waste Sorting |

|---|---|---|

| Definition | Manual segregation of waste at the point of disposal | Automated sorting using AI and sensors in waste processing facilities |

| Efficiency | Depends on user compliance; variable accuracy | High accuracy with real-time sorting capabilities |

| Cost | Low initial cost; higher labor expenses over time | High initial investment; reduced operational costs |

| Environmental Impact | Reduces contamination if properly done | Maximizes material recovery and reduces landfill waste |

| Scalability | Limited by public participation and education | Scalable with technology upgrades and infrastructure |

| Technology Use | Minimal; relies on manual effort | Advanced AI, machine learning, and sensor integration |

| Waste Types Handled | Common recyclables and organics | Broad range including complex materials and mixed waste |

Introduction to Source Separation and Smart Waste Sorting

Source separation involves the manual sorting of waste at its origin, enabling efficient recycling and reducing contamination by categorizing materials like paper, plastics, and organic waste before collection. Smart waste sorting integrates advanced technologies such as AI, robotics, and sensor-based systems to automatically identify and separate waste streams, increasing accuracy and processing speed in recycling facilities. Combining these methods enhances overall waste management efficiency, minimizes landfill use, and supports circular economy goals.

Defining Source Separation in Waste Management

Source separation in waste management refers to the practice of segregating waste streams at the point of origin, such as households or businesses, to enhance recycling efficiency and reduce contamination. This method enables the collection of cleaner materials like paper, plastics, organics, and metals, facilitating higher quality recycling outputs. Compared to smart waste sorting technologies, source separation reduces reliance on complex sorting systems and lowers operational costs by minimizing the need for post-collection processing.

What is Smart Waste Sorting?

Smart waste sorting utilizes advanced technologies like AI, sensors, and robotics to automatically identify and separate recyclable materials from mixed waste streams, enhancing efficiency and accuracy compared to traditional source separation methods. This automated process reduces contamination, increases recycling rates, and optimizes waste management operations by enabling real-time sorting decisions. Implementing smart waste sorting systems supports sustainable waste handling and contributes to circular economy goals by maximizing material recovery.

Key Technologies in Smart Waste Sorting

Smart waste sorting leverages key technologies such as advanced sensors, artificial intelligence (AI), and robotics to enhance the efficiency of separating recyclables from waste streams. Optical sensors utilize near-infrared (NIR) and hyperspectral imaging to accurately identify material types, while AI algorithms enable real-time decision-making for sorting processes. Robotics equipped with machine learning capabilities automate material handling, increasing sorting speed and minimizing contamination compared to traditional source separation methods.

Benefits of Source Separation Methods

Source separation methods enhance recycling efficiency by reducing contamination and improving material quality, leading to higher-value recovered resources and lower processing costs. These methods enable more accurate sorting at the point of waste generation, which minimizes landfill volume and greenhouse gas emissions. Implementing source separation also promotes public awareness and participation in sustainable waste management practices, contributing to circular economy goals.

Advantages of Smart Waste Sorting Solutions

Smart waste sorting solutions leverage advanced technologies such as AI, sensors, and machine learning to accurately identify and separate recyclables from mixed waste, significantly increasing recycling rates and reducing contamination. These systems optimize waste management operations by automating sorting processes, lowering labor costs, and enhancing material recovery efficiency. The precise separation capabilities minimize landfill usage and support sustainable resource circulation, making smart sorting superior to traditional source separation methods.

Challenges Faced by Source Separation Systems

Source separation systems face challenges such as inconsistent sorting by households, leading to contamination of recyclable streams and reduced material quality. Limited public awareness and participation hinder proper segregation, causing inefficiencies in collection and processing. Infrastructure constraints and inadequate enforcement further complicate maintaining high compliance and reducing cross-contamination.

Obstacles in Implementing Smart Waste Sorting

Smart waste sorting faces significant obstacles such as high initial investment costs for advanced sensor technologies and AI systems, limiting adoption in low-income regions. Technical challenges, including inconsistent waste stream compositions and sensor accuracy, reduce sorting efficiency and increase contamination rates. Regulatory barriers and lack of standardized protocols also hinder integration with existing waste management infrastructures.

Comparative Analysis: Source Separation vs Smart Waste Sorting

Source separation involves households and businesses sorting waste at the point of disposal, which enhances material recovery rates and reduces contamination. Smart waste sorting leverages advanced technologies like AI and sensors to automate classification and separation, improving efficiency and scalability in waste processing facilities. While source separation relies on user compliance and education, smart sorting offers consistent precision, making the combination of both strategies optimal for maximizing recycling outcomes and minimizing landfill waste.

Future Trends in Waste Sorting Technologies

Future trends in waste sorting technologies emphasize the integration of advanced AI-powered smart waste sorting systems that enhance accuracy and efficiency beyond traditional source separation. Innovations in sensor technology, robotics, and machine learning enable real-time material identification and automated sorting, reducing contamination and increasing recycling rates. Emerging solutions prioritize seamless integration with circular economy models, driving sustainable waste management and resource recovery at scale.

Related Important Terms

Multi-Stream Separation

Multi-stream source separation involves residents or businesses sorting waste into distinct categories such as organics, recyclables, and landfill-bound materials at the point of disposal, enhancing contamination reduction and material recovery rates. Smart waste sorting utilizes advanced technologies like AI-driven sensors and robotics to automatically identify and separate waste streams, improving efficiency and accuracy compared to manual multi-stream separation methods.

Optical Sorters

Optical sorters utilize advanced sensor technology such as near-infrared (NIR) and hyperspectral imaging to accurately identify and separate recyclable materials, enhancing the efficiency and purity of sorted waste streams compared to manual source separation methods. This technology significantly reduces contamination rates and operational costs in waste management facilities by automating high-speed sorting of plastics, paper, metals, and glass with precision.

AI-Driven Sorting

AI-driven sorting systems enhance source separation by using advanced machine learning algorithms to identify and categorize waste materials with high precision, reducing contamination and improving recycling rates. These smart waste sorting technologies leverage image recognition, sensor data, and robotics to automate the sorting process, thereby increasing efficiency and lowering operational costs compared to traditional manual separation methods.

Robotic Waste Picking

Robotic waste picking enhances smart waste sorting by automating the identification and separation of recyclables from mixed waste streams, improving efficiency compared to traditional source separation methods. Advanced AI-powered robots utilize computer vision and machine learning to precisely sort materials, reducing contamination and increasing recycling rates in waste management systems.

IoT-Enabled Bins

IoT-enabled bins enhance source separation by using sensors and real-time data to accurately identify and segregate waste at the point of disposal, reducing contamination and improving recycling rates. Smart waste sorting systems complement this by employing AI and robotics to further classify and process collected waste, resulting in higher efficiency and resource recovery.

Bin-Level Sensorization

Bin-level sensorization enhances source separation by providing real-time data on waste composition and fill levels, enabling more efficient sorting processes at the point of disposal. Integrating smart waste sorting systems with sensorized bins improves contamination detection and reduces manual sorting costs, optimizing overall waste management efficiency.

Digital Twin Waste Mapping

Source separation enhances waste management by encouraging individuals to sort recyclables at the point of disposal, reducing contamination and improving material recovery rates. Digital twin waste mapping leverages real-time data and virtual models to optimize smart waste sorting processes, enabling precise identification and segregation of waste streams for increased recycling efficiency.

Material Recovery Facility (MRF) Automation

Source separation significantly enhances the efficiency of Material Recovery Facility (MRF) automation by delivering pre-sorted recyclable materials, reducing contamination and operational costs. Advanced smart waste sorting technologies complement this process by utilizing AI-driven sensors and robotic arms to further improve material recovery rates and streamline facility throughput.

SMART Labeling (Standardized Material and Residue Tagging)

SMART Labeling (Standardized Material and Residue Tagging) enhances waste management by enabling precise identification and segregation of materials during smart waste sorting, significantly reducing contamination rates compared to traditional source separation methods. This technology integrates RFID and QR codes to provide real-time data on waste composition, facilitating efficient recycling processes and improving overall waste stream quality.

Pay-As-You-Throw (PAYT) Analytics

Source separation improves waste management efficiency by enabling accurate categorization at the point of disposal, resulting in higher recycling rates and reduced contamination. Pay-As-You-Throw (PAYT) analytics enhance this process by providing data-driven insights into waste generation patterns, incentivizing users to minimize waste and optimize smart waste sorting technologies.

Source Separation vs Smart Waste Sorting Infographic

industrydif.com

industrydif.com