Waste management involves the systematic collection, treatment, and disposal of waste to minimize environmental impact, often relying on landfills and recycling programs. Zero waste design emphasizes the creation of products and systems that eliminate waste generation entirely by encouraging reuse, redesign, and sustainable material choices. Prioritizing zero waste design can reduce the reliance on traditional waste management methods and promote a circular economy.

Table of Comparison

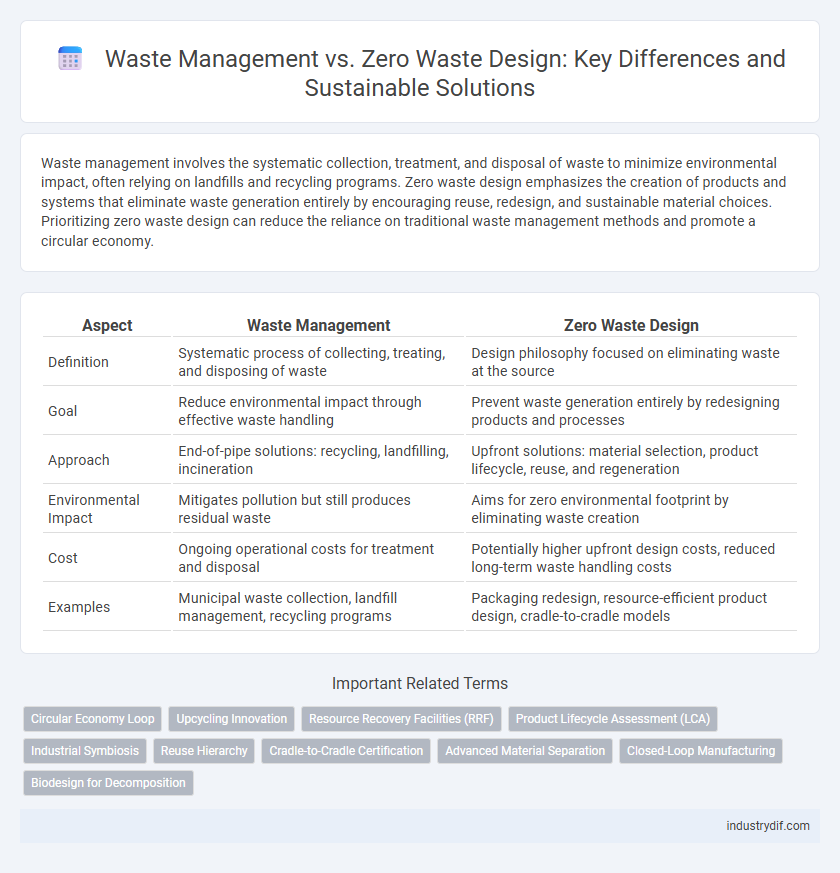

| Aspect | Waste Management | Zero Waste Design |

|---|---|---|

| Definition | Systematic process of collecting, treating, and disposing of waste | Design philosophy focused on eliminating waste at the source |

| Goal | Reduce environmental impact through effective waste handling | Prevent waste generation entirely by redesigning products and processes |

| Approach | End-of-pipe solutions: recycling, landfilling, incineration | Upfront solutions: material selection, product lifecycle, reuse, and regeneration |

| Environmental Impact | Mitigates pollution but still produces residual waste | Aims for zero environmental footprint by eliminating waste creation |

| Cost | Ongoing operational costs for treatment and disposal | Potentially higher upfront design costs, reduced long-term waste handling costs |

| Examples | Municipal waste collection, landfill management, recycling programs | Packaging redesign, resource-efficient product design, cradle-to-cradle models |

Defining Waste Management and Zero Waste Design

Waste management involves the systematic collection, treatment, and disposal of waste materials to minimize environmental impact and ensure public health and safety. Zero waste design emphasizes creating products and systems that eliminate waste generation through resource efficiency, reuse, and recycling, aiming for a closed-loop lifecycle. Both approaches target sustainability but differ in focus: waste management handles existing waste, while zero waste design prevents waste creation at the source.

Key Principles of Waste Management

Waste management focuses on the systematic collection, transportation, processing, recycling, and disposal of waste to minimize environmental impact. Key principles include waste hierarchy prioritizing reduction, reuse, and recycling, alongside compliance with regulatory frameworks and promoting sustainable resource recovery. In contrast, zero waste design emphasizes eliminating waste generation through product redesign and closed-loop systems, aiming for total resource efficiency.

Fundamentals of Zero Waste Design

Zero Waste Design prioritizes eliminating waste at the source by rethinking product life cycles, emphasizing durability, repairability, and recyclability of materials. Unlike traditional Waste Management, which focuses on collection, recycling, and disposal after waste generation, Zero Waste Design integrates sustainable material selection and circular economy principles from the initial design phase. This proactive approach reduces environmental impact and resource consumption by designing products and systems that inherently minimize or eliminate waste production.

Comparing Goals: Disposal vs Elimination

Waste management focuses on safe disposal and treatment of waste to minimize environmental impact, prioritizing containment and reduction of hazards associated with trash. Zero waste design aims at eliminating waste generation entirely through sustainable production processes and product lifecycle planning, promoting circular economy principles. While waste management mitigates problems after waste is created, zero waste design seeks to prevent waste creation altogether, fostering long-term sustainability.

Material Flow: Linear vs Circular Approaches

Waste management involves a linear material flow where resources are extracted, used, and disposed of, often leading to environmental pollution and resource depletion. In contrast, zero waste design embraces a circular approach that prioritizes resource recovery, reuse, and recycling to eliminate waste generation entirely. Circular material flow reduces landfill dependency and supports sustainable resource efficiency across product life cycles.

Industrial Applications and Best Practices

Industrial applications prioritize waste management strategies such as material recovery, recycling, and hazardous waste treatment to minimize environmental impact and comply with regulations. Zero waste design emphasizes reducing waste generation at the source by redesigning products and processes to optimize resource efficiency and eliminate landfill disposal. Best practices integrate life cycle assessment, closed-loop systems, and circular economy principles to achieve sustainable industrial operations and reduce overall waste footprints.

Environmental Impact Assessment

Waste management involves the systematic collection, treatment, and disposal of waste to reduce environmental harm, while zero waste design emphasizes eliminating waste generation through resource-efficient product and process innovations. Environmental Impact Assessment (EIA) of waste management systems highlights emissions, landfill use, and resource depletion, whereas zero waste design aims to minimize these impacts by prioritizing reuse, recycling, and circular economy principles. Integrating zero waste design within EIA frameworks enhances sustainability by reducing pollution, conserving resources, and promoting long-term ecological balance.

Challenges and Limitations in Implementation

Waste management systems face challenges such as limited recycling infrastructure, high operational costs, and inconsistent regulatory frameworks that hinder effective waste diversion. Zero waste design implementation struggles with product complexity, lack of standardized eco-design criteria, and consumer behavior resistance, which limit widespread adoption. Both approaches require significant cultural shifts and investment to overcome these systemic barriers and achieve sustainable waste reduction.

Economic Implications and Cost Analysis

Waste management systems often incur substantial operational expenses related to collection, processing, and landfill maintenance, while zero waste design emphasizes waste prevention through resource efficiency and product lifecycle extension, reducing long-term costs. Economic implications of zero waste designs include lower material purchase costs, decreased waste disposal fees, and potential revenue from recyclable or reusable materials, which can enhance profitability and economic sustainability. Cost analysis reveals that investments in zero waste design may involve upfront expenses but yield significant savings by minimizing waste generation and fostering circular economy principles.

Future Trends in Sustainable Waste Strategies

Future trends in sustainable waste strategies emphasize the integration of advanced waste management technologies with zero waste design principles to minimize landfill dependency and resource consumption. Innovations in circular economy models, such as closed-loop recycling systems and product redesign for disassembly, are driving reductions in material waste and enhancing resource recovery. Embracing smart waste tracking and AI-powered sorting technologies facilitates higher efficiency and accuracy, aligning waste management practices with zero waste goals for a more sustainable future.

Related Important Terms

Circular Economy Loop

Waste management focuses on efficient collection, processing, and disposal of materials to minimize environmental impact, while zero waste design emphasizes eliminating waste generation through product lifecycle planning and sustainable materials. Integrating zero waste principles within the circular economy loop enhances resource recovery, promotes continuous material reuse, and reduces reliance on landfill and incineration.

Upcycling Innovation

Upcycling innovation in waste management transforms discarded materials into higher-value products, reducing landfill dependency and minimizing environmental footprint. Zero waste design integrates this approach by prioritizing resource efficiency and product longevity, fostering sustainable consumption patterns through creative reuse and material optimization.

Resource Recovery Facilities (RRF)

Resource Recovery Facilities (RRF) play a crucial role in waste management by processing mixed waste streams to extract valuable materials, thereby reducing landfill reliance and enabling circular economy practices. Zero Waste Design emphasizes eliminating waste generation at the source, minimizing the need for RRFs through sustainable product lifecycle strategies and material selection.

Product Lifecycle Assessment (LCA)

Product Lifecycle Assessment (LCA) is crucial in waste management for evaluating environmental impacts across a product's entire lifecycle, from raw material extraction to disposal. Zero Waste Design leverages LCA to minimize waste generation by optimizing product materials, durability, and recyclability, promoting sustainable consumption and circular economy principles.

Industrial Symbiosis

Industrial symbiosis in waste management leverages the exchange of materials, energy, and by-products between industries to minimize waste generation and maximize resource efficiency, promoting a circular economy. Zero waste design integrates this concept by engineering processes and products that eliminate waste production altogether, enabling industries to function as interconnected systems that recycle and repurpose outputs continuously.

Reuse Hierarchy

Waste management prioritizes the reuse hierarchy by focusing on reducing, reusing, and recycling materials to minimize landfill waste, while zero waste design aims to eliminate waste entirely through product and process innovation that promotes continuous reuse and resource recovery. Implementing zero waste design incorporates the reuse hierarchy by emphasizing durable, repairable, and recyclable products that support circular economy principles and reduce environmental impact.

Cradle-to-Cradle Certification

Cradle-to-Cradle Certification emphasizes designing products for continuous recovery and reuse, minimizing waste through sustainable material cycles rather than simply managing waste after it is generated. Zero Waste Design integrates this concept by prioritizing elimination of waste at the source, contrasting with traditional waste management approaches that focus primarily on disposal and recycling.

Advanced Material Separation

Advanced material separation enhances waste management efficiency by enabling precise sorting of recyclables and reducing landfill volumes. Zero waste design prioritizes material reuse and elimination of waste generation through product lifecycle innovation, minimizing the need for extensive separation technologies.

Closed-Loop Manufacturing

Closed-loop manufacturing in waste management prioritizes recycling and reusing materials within the production process to minimize waste generation and resource consumption. Zero waste design pushes this further by creating products and systems that eliminate waste entirely through sustainable materials and lifecycle thinking, fostering a circular economy with minimal environmental impact.

Biodesign for Decomposition

Waste management strategies often rely on treatment and disposal systems, whereas zero waste design emphasizes eliminating waste generation through circular principles. Biodesign leverages natural decomposition processes by incorporating biodegradable materials and ecosystems, promoting sustainable waste cycling and reducing landfill dependency.

Waste Management vs Zero Waste Design Infographic

industrydif.com

industrydif.com