Mechanical recycling involves physically processing waste materials, such as plastics and metals, by shredding and melting them to create new products, preserving their original polymer structure. Chemical recycling breaks down waste at the molecular level through processes like pyrolysis or depolymerization, enabling recovery of monomers for producing virgin-quality materials. Mechanical recycling is cost-effective and widely used but limited by material contamination and degradation, while chemical recycling offers higher purity and versatility but requires more energy and advanced technology.

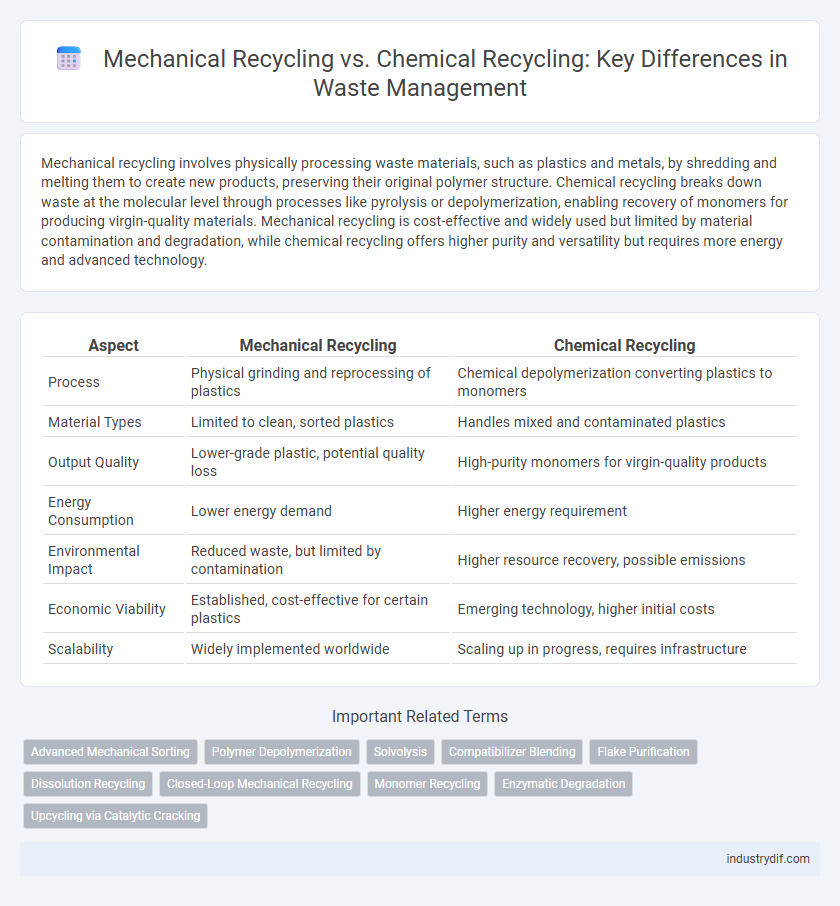

Table of Comparison

| Aspect | Mechanical Recycling | Chemical Recycling |

|---|---|---|

| Process | Physical grinding and reprocessing of plastics | Chemical depolymerization converting plastics to monomers |

| Material Types | Limited to clean, sorted plastics | Handles mixed and contaminated plastics |

| Output Quality | Lower-grade plastic, potential quality loss | High-purity monomers for virgin-quality products |

| Energy Consumption | Lower energy demand | Higher energy requirement |

| Environmental Impact | Reduced waste, but limited by contamination | Higher resource recovery, possible emissions |

| Economic Viability | Established, cost-effective for certain plastics | Emerging technology, higher initial costs |

| Scalability | Widely implemented worldwide | Scaling up in progress, requires infrastructure |

Overview of Mechanical and Chemical Recycling

Mechanical recycling involves physically processing waste materials, such as plastics, by sorting, shredding, and melting them to create new products without altering their chemical structure. Chemical recycling breaks down waste into its molecular components through processes like pyrolysis, gasification, or depolymerization, enabling the production of raw materials for new polymers. Both methods aim to reduce landfill waste, with mechanical recycling typically being more energy-efficient while chemical recycling offers the potential to handle mixed or contaminated plastics.

Key Differences Between Mechanical and Chemical Recycling

Mechanical recycling involves physically processing waste plastics through sorting, shredding, and melting to produce new materials, preserving polymer structure but with potential quality degradation. Chemical recycling breaks down plastics into their basic chemical components, allowing for the removal of contaminants and regeneration of virgin-quality polymers. Mechanical recycling is more energy-efficient but limited by contamination sensitivity, whereas chemical recycling offers greater material recovery flexibility but requires higher energy input and complex technology.

Process Flow: Mechanical Recycling Explained

Mechanical recycling involves physically processing waste materials, primarily plastics, through sorting, shredding, washing, and melting to produce reusable raw materials. This method maintains the polymer's chemical structure, allowing repeated reuse with minimal alteration to the material's properties. Its process flow emphasizes energy efficiency and lower environmental impact compared to chemical recycling, which breaks down polymers chemically.

Process Flow: Chemical Recycling Demystified

Chemical recycling transforms plastic waste into basic chemical components through processes like pyrolysis, depolymerization, and gasification, enabling the recovery of valuable monomers and feedstocks. Unlike mechanical recycling, which physically melts and remolds plastics, chemical recycling breaks polymers down at the molecular level, allowing for the treatment of mixed or contaminated plastics that are unsuitable for mechanical methods. This process flow enhances material circularity by producing high-quality outputs that can re-enter the polymer production cycle with minimal degradation.

Types of Plastics Suitable for Mechanical vs Chemical Recycling

Mechanical recycling is primarily suitable for thermoplastics such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP), which retain their properties through repeated melting and reshaping. Chemical recycling can process a broader range of plastics, including thermosets like epoxy resins and mixed or contaminated plastics, by breaking polymer chains into monomers or other basic chemicals. This flexibility makes chemical recycling valuable for plastics that degrade in quality during mechanical recycling or are otherwise challenging to recycle mechanically.

Environmental Impact Comparison

Mechanical recycling preserves the original polymer structure, resulting in lower energy consumption and reduced greenhouse gas emissions compared to chemical recycling, which breaks down plastics into monomers. Chemical recycling offers the advantage of processing contaminated or mixed waste streams that mechanical methods cannot, but it typically requires higher temperatures and generates more carbon dioxide. Life cycle assessments indicate mechanical recycling has a smaller carbon footprint, while chemical recycling contributes benefits by diverting non-recyclable plastics from landfills and reducing fossil fuel dependence.

Economic Feasibility and Market Adoption

Mechanical recycling offers lower operational costs and established market channels, making it economically feasible for high-volume, uniform plastic waste streams. Chemical recycling, while capable of processing mixed and contaminated plastics, faces higher energy requirements and capital investment, limiting large-scale market adoption. Market demand increasingly favors chemical recycling technology for its ability to create high-purity outputs despite current economic and scalability challenges.

Quality and End Use of Recycled Materials

Mechanical recycling preserves the polymer's original structure, resulting in recycled materials with moderate quality suited for packaging, containers, and textiles. Chemical recycling breaks down plastics into monomers, producing higher-quality, virgin-equivalent polymers ideal for automotive parts, electronics, and food-grade applications. The enhanced purity from chemical recycling expands the end-use possibilities, overcoming contamination and degradation issues common in mechanical recycling.

Challenges and Limitations

Mechanical recycling faces challenges such as contamination, degradation of polymer quality, and limited effectiveness with mixed or composite plastics, restricting the range of recyclable materials. Chemical recycling encounters limitations including high energy consumption, complex processing technologies, and economic viability concerns due to fluctuating market demand and raw material costs. Both methods struggle with scalability and regulatory compliance, impacting their widespread adoption and environmental benefits.

Future Trends in Recycling Technologies

Mechanical recycling remains the dominant method for processing plastic waste due to its cost-effectiveness and widespread infrastructure. Emerging chemical recycling technologies, including pyrolysis and depolymerization, offer the potential to convert complex and contaminated plastics back into their original monomers or fuels, addressing limitations of mechanical processes. Future trends highlight hybrid recycling systems that integrate both mechanical and chemical techniques to maximize material recovery and support a circular economy.

Related Important Terms

Advanced Mechanical Sorting

Advanced mechanical sorting leverages cutting-edge sensor technologies like near-infrared (NIR) and hyperspectral imaging to efficiently separate polymers, enhancing the purity and yield of recycled plastics. This process reduces contamination and energy consumption compared to chemical recycling, making it a cost-effective and environmentally sustainable solution for processing multi-material waste streams.

Polymer Depolymerization

Mechanical recycling preserves polymer structure by physically processing waste plastics, but it degrades material quality over multiple cycles, limiting its effectiveness. Chemical recycling, specifically polymer depolymerization, breaks down polymers into monomers or basic chemicals, enabling the production of virgin-quality plastics and supporting a circular economy for materials like PET and polystyrene.

Solvolysis

Mechanical recycling processes plastic waste by physically shredding and melting materials, preserving polymer chains but limiting the recycling of contaminated or mixed plastics. Solvolysis, a chemical recycling method, uses solvents to depolymerize plastics like PET into monomers, enabling superior purity and the potential for closed-loop recycling with fewer material downgrades.

Compatibilizer Blending

Mechanical recycling relies on compatibilizer blending to enhance the interfacial adhesion between mixed polymer types, improving the physical properties of recycled plastics. Chemical recycling breaks down polymers into monomers, reducing the need for compatibilizers but often at higher energy costs and processing complexity.

Flake Purification

Mechanical recycling relies on flake purification processes such as washing, density separation, and friction to remove contaminants and improve polymer quality, while chemical recycling breaks down plastic flake into monomers for higher-purity feedstock production. Flake purification in mechanical recycling is limited by residual additives and degradation, whereas chemical recycling achieves higher material recovery by enabling depolymerization and removal of additives at the molecular level.

Dissolution Recycling

Mechanical recycling involves physically processing waste materials like plastics through shredding and remelting, preserving polymer chains but often leading to quality degradation. Dissolution recycling, a subset of chemical recycling, selectively dissolves specific polymers without breaking their chemical structure, enabling higher-quality material recovery and reducing contamination issues compared to traditional mechanical methods.

Closed-Loop Mechanical Recycling

Closed-loop mechanical recycling preserves material quality by continuously reprocessing waste plastics into identical products without chemical alteration, reducing plastic waste and demand for virgin resources. This method is energy-efficient and economically viable compared to chemical recycling, which breaks polymers into monomers but requires higher energy input and complex processing.

Monomer Recycling

Mechanical recycling preserves the physical properties of plastics by shredding and reprocessing waste but often results in material degradation. Chemical recycling, specifically monomer recycling, breaks polymers down to their basic monomers, enabling the production of virgin-quality plastics and closing the loop for materials like PET and polystyrene.

Enzymatic Degradation

Mechanical recycling maintains plastic polymer integrity by shredding and remelting materials, while enzymatic degradation in chemical recycling uses specific enzymes to break down polymers at a molecular level, enabling the recovery of monomers for high-purity plastic regeneration. Enzymatic degradation offers a sustainable alternative by enhancing biodegradability and reducing energy consumption compared to traditional mechanical and chemical recycling methods.

Upcycling via Catalytic Cracking

Mechanical recycling preserves plastic integrity by shredding and melting waste, but its limitations include polymer degradation and contamination sensitivity. Chemical recycling, particularly catalytic cracking, upcycles plastic waste by breaking polymer chains into valuable hydrocarbons, enabling the production of high-quality fuels and raw materials with enhanced sustainability.

Mechanical Recycling vs Chemical Recycling Infographic

industrydif.com

industrydif.com