Chlorination is a widely used water disinfection method that effectively kills bacteria and viruses by releasing chlorine compounds, but it can produce harmful disinfection byproducts. UV-C treatment disinfects water by using ultraviolet light to disrupt the DNA of microorganisms, offering a chemical-free alternative without residual taste or odor. While UV-C requires clear water for optimal effectiveness, chlorination provides longer-lasting residual protection in distribution systems.

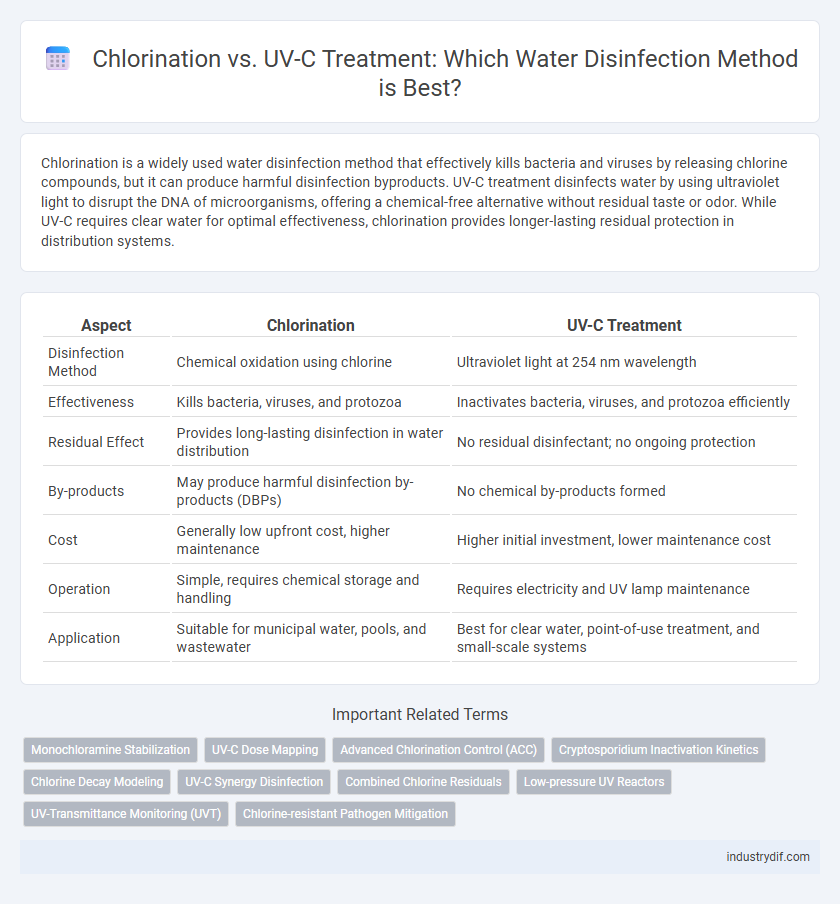

Table of Comparison

| Aspect | Chlorination | UV-C Treatment |

|---|---|---|

| Disinfection Method | Chemical oxidation using chlorine | Ultraviolet light at 254 nm wavelength |

| Effectiveness | Kills bacteria, viruses, and protozoa | Inactivates bacteria, viruses, and protozoa efficiently |

| Residual Effect | Provides long-lasting disinfection in water distribution | No residual disinfectant; no ongoing protection |

| By-products | May produce harmful disinfection by-products (DBPs) | No chemical by-products formed |

| Cost | Generally low upfront cost, higher maintenance | Higher initial investment, lower maintenance cost |

| Operation | Simple, requires chemical storage and handling | Requires electricity and UV lamp maintenance |

| Application | Suitable for municipal water, pools, and wastewater | Best for clear water, point-of-use treatment, and small-scale systems |

Introduction to Water Disinfection Methods

Chlorination is a widely used water disinfection method that involves adding chlorine compounds to eliminate pathogenic bacteria, viruses, and protozoa, ensuring safe drinking water. UV-C treatment utilizes ultraviolet light at wavelengths around 254 nm to disrupt microbial DNA, effectively inactivating microorganisms without chemical residues. Both methods provide reliable microbial control, but chlorination offers residual disinfection in distribution systems while UV-C treatment requires consistent exposure and clear water for optimal efficacy.

Understanding Chlorination in Water Treatment

Chlorination remains a widely used water treatment method due to its strong disinfectant properties and residual protection in distribution systems. It effectively eliminates pathogenic microorganisms by oxidizing cell membranes, ensuring microbial safety in drinking water. Although chlorination can produce disinfection byproducts like trihalomethanes, careful monitoring and dosage control minimize health risks while maintaining regulatory standards.

Exploring UV-C Treatment Technology

UV-C treatment technology offers a chemical-free method to disinfect water by using ultraviolet light at wavelengths between 200-280 nanometers to inactivate bacteria, viruses, and protozoa effectively. Unlike chlorination, UV-C does not produce harmful disinfection byproducts such as trihalomethanes, making it a safer option for drinking water and wastewater applications. Advances in UV-C LEDs and lamp design have improved energy efficiency and lifespan, enhancing the adoption of this sustainable water purification technology worldwide.

Mechanisms of Chlorination vs UV-C Disinfection

Chlorination disinfects water by releasing hypochlorous acid, which penetrates microbial cell walls, disrupting enzymes and cellular functions to inactivate pathogens. UV-C treatment employs ultraviolet light at a wavelength of 254 nm, damaging the DNA and RNA of microorganisms, preventing replication and rendering them inactive. Both methods effectively reduce microbial contamination, but chlorination offers residual disinfection while UV-C provides rapid inactivation without chemical byproducts.

Efficacy of Pathogen Elimination

Chlorination effectively eliminates a broad spectrum of pathogens, including bacteria, viruses, and protozoa, by disrupting their cellular functions through chemical oxidation. UV-C treatment inactivates microorganisms by damaging their DNA or RNA, rendering them unable to reproduce, with high efficacy against chlorine-resistant pathogens such as Cryptosporidium and Giardia. Both methods offer reliable pathogen control, but UV-C provides a chemical-free option with rapid disinfection and minimal formation of harmful byproducts.

Chemical Byproducts: Risks and Regulations

Chlorination in water treatment produces chemical byproducts such as trihalomethanes (THMs) and haloacetic acids (HAAs), both linked to health risks including cancer and reproductive issues, prompting strict regulations by the EPA and WHO. UV-C treatment avoids these harmful byproducts by using ultraviolet light to inactivate pathogens without chemical addition, offering a safer alternative for disinfection. Regulatory frameworks continue prioritizing the reduction of chemical residuals, making UV-C an increasingly favored technology for minimizing water treatment risks.

Operational Costs and Energy Consumption

Chlorination involves lower initial setup costs but higher ongoing expenses due to chemical procurement and handling, leading to fluctuating operational costs. UV-C treatment demands a higher upfront investment for equipment and lamps yet benefits from consistent energy consumption and minimal chemical needs, resulting in more stable long-term costs. Energy consumption for UV-C systems depends on lamp wattage and water flow rates, often making it more efficient for smaller-scale applications compared to chlorination's chemical production and transportation energy footprint.

Environmental Impact: Chlorination vs UV-C

Chlorination releases harmful disinfection byproducts such as trihalomethanes and haloacetic acids, which pose risks to aquatic ecosystems and human health. UV-C treatment provides a chemical-free alternative that effectively inactivates pathogens without generating toxic residues or altering water chemistry. This makes UV-C a more environmentally sustainable option for water disinfection with minimal ecological footprint.

Maintenance and System Scalability

Chlorination systems require regular monitoring of chemical levels and periodic replacement of dosing equipment to ensure effective disinfection, making maintenance relatively labor-intensive. UV-C treatment units have low maintenance demands, mainly involving periodic lamp replacement and cleaning of quartz sleeves, which enhances operational efficiency. Scalability is straightforward for UV-C systems due to modular lamp arrays adaptable to varying flow rates, while chlorination scalability depends on chemical storage capacity and dosage control adjustments.

Choosing the Optimal Disinfection Method for Your Facility

Chlorination offers effective residual disinfection and is cost-efficient for large-scale water treatment but may produce harmful disinfection byproducts like trihalomethanes. UV-C treatment provides rapid inactivation of a wide range of pathogens without chemical additives, making it environmentally friendly and ideal for facilities prioritizing chemical-free processes. Selecting the optimal method depends on factors such as water quality, facility size, regulatory requirements, and operational costs to ensure safe, compliant, and sustainable water treatment.

Related Important Terms

Monochloramine Stabilization

Chlorination using monochloramine stabilization offers prolonged disinfectant residuals in water distribution systems, effectively minimizing microbial regrowth compared to UV-C treatment, which provides rapid inactivation but lacks residual protection. Monochloramine's stability reduces formation of harmful byproducts like trihalomethanes, enhancing water safety and regulatory compliance over traditional chlorination methods.

UV-C Dose Mapping

UV-C dose mapping ensures precise measurement and distribution of ultraviolet light intensity, optimizing microbial inactivation in water treatment systems. Accurate dose mapping enhances the efficacy of UV-C treatment by identifying low-dose zones and enabling targeted adjustments, outperforming traditional chlorination in controlling pathogens without chemical residues.

Advanced Chlorination Control (ACC)

Advanced Chlorination Control (ACC) enhances traditional chlorination by precisely regulating chlorine dosing to minimize harmful byproducts while ensuring effective disinfection. UV-C treatment complements ACC by targeting a broad spectrum of pathogens through ultraviolet light, offering a chemical-free alternative that reduces reliance on chlorine-based methods.

Cryptosporidium Inactivation Kinetics

Chlorination exhibits slower inactivation kinetics against Cryptosporidium oocysts due to their resistance to chemical disinfectants, requiring prolonged contact times and higher chlorine doses for effective control. UV-C treatment rapidly inactivates Cryptosporidium by damaging its DNA, achieving significant reduction within seconds at doses typically around 10-40 mJ/cm2, making it a preferred method for targeting resistant protozoan pathogens in water treatment.

Chlorine Decay Modeling

Chlorine decay modeling is essential for optimizing chlorination processes by predicting the rate at which residual chlorine diminishes in water distribution systems, ensuring effective disinfection and compliance with safety standards. This model accounts for variables such as water temperature, pH, organic matter concentration, and pipe material, providing precise control over chlorine dosage and minimizing the formation of harmful disinfection byproducts.

UV-C Synergy Disinfection

UV-C Synergy disinfection leverages ultraviolet light at specific wavelengths to effectively inactivate pathogens by damaging their DNA, offering a chemical-free alternative to traditional chlorination. This advanced method enhances water safety by reducing harmful disinfection byproducts and providing rapid microbial control, making it ideal for sensitive environments and improving overall water quality.

Combined Chlorine Residuals

Chlorination often leads to the formation of combined chlorine residuals, such as chloramines, which can cause taste and odor issues and reduce disinfection efficiency. UV-C treatment effectively inactivates pathogens without producing combined chlorine residuals, making it a preferred option for maintaining water quality without chemical byproducts.

Low-pressure UV Reactors

Low-pressure UV reactors provide energy-efficient disinfection by emitting UV-C light at 254 nm, effectively inactivating pathogens without introducing chemicals like chlorine. Unlike chlorination, which can form harmful disinfection byproducts such as trihalomethanes, UV-C treatment ensures safer water quality by avoiding residual chemical contaminants.

UV-Transmittance Monitoring (UVT)

UV-Transmittance (UVT) monitoring is essential in UV-C water treatment to measure the water's clarity and ensure effective pathogen inactivation, as low UVT values reduce the penetration of UV light and diminish disinfection efficiency. Chlorination does not require UVT monitoring, making UV-C treatment more sensitive to water quality variations and demanding precise UVT measurement for optimal system performance.

Chlorine-resistant Pathogen Mitigation

Chlorination effectively targets a broad spectrum of waterborne pathogens but struggles against certain chlorine-resistant microorganisms like Cryptosporidium and Giardia, which can survive standard chlorine levels. UV-C treatment offers enhanced inactivation of these chlorine-resistant pathogens by disrupting their DNA and preventing replication, making it a critical complementary method for comprehensive water disinfection.

Chlorination vs UV-C Treatment Infographic

industrydif.com

industrydif.com