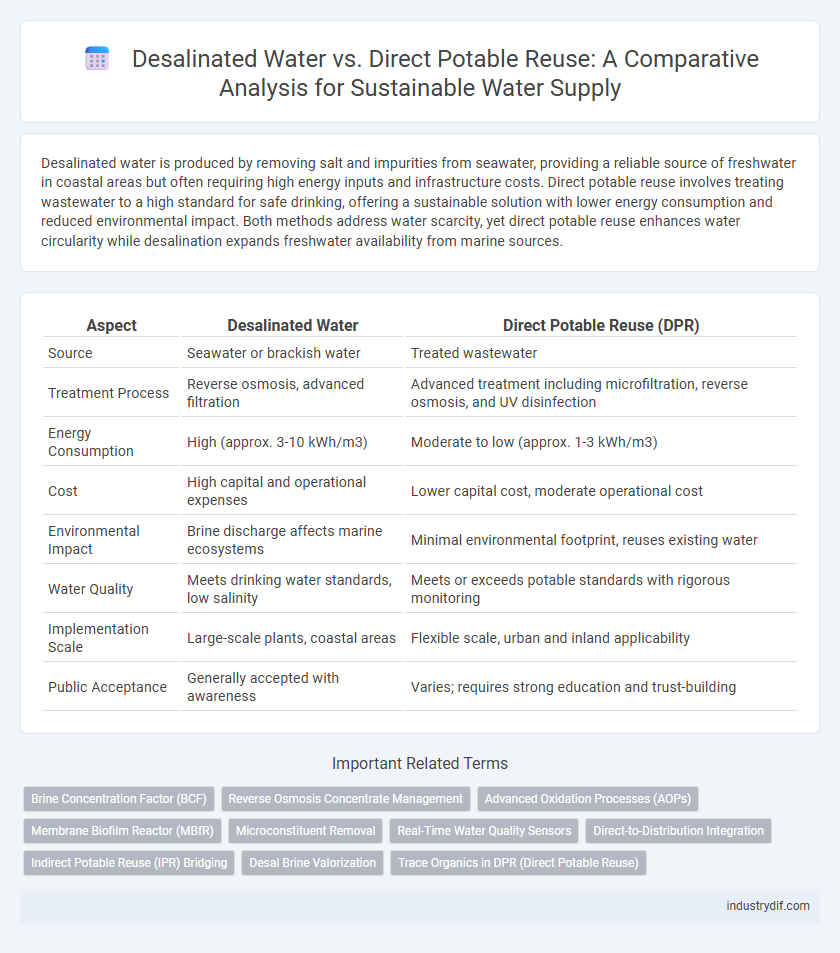

Desalinated water is produced by removing salt and impurities from seawater, providing a reliable source of freshwater in coastal areas but often requiring high energy inputs and infrastructure costs. Direct potable reuse involves treating wastewater to a high standard for safe drinking, offering a sustainable solution with lower energy consumption and reduced environmental impact. Both methods address water scarcity, yet direct potable reuse enhances water circularity while desalination expands freshwater availability from marine sources.

Table of Comparison

| Aspect | Desalinated Water | Direct Potable Reuse (DPR) |

|---|---|---|

| Source | Seawater or brackish water | Treated wastewater |

| Treatment Process | Reverse osmosis, advanced filtration | Advanced treatment including microfiltration, reverse osmosis, and UV disinfection |

| Energy Consumption | High (approx. 3-10 kWh/m3) | Moderate to low (approx. 1-3 kWh/m3) |

| Cost | High capital and operational expenses | Lower capital cost, moderate operational cost |

| Environmental Impact | Brine discharge affects marine ecosystems | Minimal environmental footprint, reuses existing water |

| Water Quality | Meets drinking water standards, low salinity | Meets or exceeds potable standards with rigorous monitoring |

| Implementation Scale | Large-scale plants, coastal areas | Flexible scale, urban and inland applicability |

| Public Acceptance | Generally accepted with awareness | Varies; requires strong education and trust-building |

Introduction to Desalinated Water and Direct Potable Reuse

Desalinated water is produced by removing salts and impurities from seawater or brackish water through processes like reverse osmosis and thermal distillation, providing a reliable source of fresh water in arid regions and coastal areas. Direct Potable Reuse (DPR) involves treating wastewater through advanced purification techniques such as microfiltration, reverse osmosis, and ultraviolet disinfection to produce highly purified water that meets or exceeds drinking water standards. Both methods address water scarcity but differ in source water and treatment processes, with desalination relying on saline sources and DPR focusing on recycling treated wastewater for direct human consumption.

Key Differences Between Desalination and Direct Potable Reuse

Desalinated water is produced by removing salts and minerals from seawater or brackish water through processes like reverse osmosis, making it suitable for consumption and irrigation. Direct potable reuse involves treating wastewater to a high standard, including advanced filtration and disinfection, allowing it to be safely reintroduced into the potable water supply without environmental discharge. Key differences lie in source water type, treatment complexity, energy requirements, and environmental impact, with desalination often demanding higher energy inputs and addressing salinity, while direct potable reuse emphasizes contaminant removal and public health safety from wastewater-origin sources.

Water Quality Standards: Desalination vs DPR

Desalinated water undergoes reverse osmosis and extensive filtration to meet stringent EPA and WHO drinking water quality standards, effectively removing salts, pathogens, and contaminants. Direct potable reuse (DPR) involves advanced treatment processes such as microfiltration, reverse osmosis, and advanced oxidation, ensuring water safety by complying with potable reuse regulations established in states like California. Both methods require rigorous monitoring of trace organic compounds and microbial indicators to maintain water quality and public health protection.

Treatment Technologies in Desalination and DPR

Desalinated water relies primarily on reverse osmosis and multi-stage flash distillation to remove salts and impurities, ensuring high purity through membrane filtration and thermal processes. Direct potable reuse (DPR) employs advanced treatment trains including microfiltration, reverse osmosis, ultraviolet disinfection, and advanced oxidation processes to effectively treat wastewater to potable standards. Both technologies utilize sophisticated membrane and chemical processes, but DPR integrates source water reclamation techniques emphasizing contaminant removal and pathogen inactivation for safe drinking water production.

Energy Consumption and Environmental Impact

Desalinated water requires significantly higher energy consumption, often exceeding 3-4 kWh per cubic meter, due to the intensive reverse osmosis process, leading to increased greenhouse gas emissions and marine brine disposal issues. Direct potable reuse (DPR) utilizes advanced treatment technologies such as microfiltration, reverse osmosis, and ultraviolet disinfection but generally consumes less energy, around 1-2 kWh per cubic meter, resulting in lower carbon footprints and minimized environmental discharge. Environmental impacts of DPR are reduced compared to desalination, as it recycles wastewater within urban systems, reducing reliance on marine ecosystems and associated biodiversity risks.

Cost Comparison: Infrastructure and Operation

Desalinated water requires extensive infrastructure investment, including large-scale reverse osmosis plants and energy-intensive processes, leading to high capital and operational costs. Direct potable reuse involves advanced treatment technologies that retrofit existing wastewater facilities, resulting in lower infrastructure expenses and reduced energy consumption. Operational costs for potable reuse are generally more predictable and scalable compared to the energy-dependent and maintenance-heavy desalination systems.

Regulatory Frameworks and Compliance

Desalinated water is regulated under comprehensive frameworks such as the U.S. EPA's National Primary Drinking Water Regulations, ensuring compliance with stringent contaminant limits before distribution. Direct potable reuse (DPR) demands tailored regulatory approaches that integrate wastewater treatment standards with advanced purification processes, requiring continuous monitoring and adaptive management to meet health safety criteria. Both water sources must adhere to rigorous quality assurance protocols established by agencies like the California State Water Resources Control Board to guarantee consumer safety and environmental protection.

Public Perception and Acceptance

Public perception of desalinated water is often shaped by concerns about taste, cost, and environmental impact, whereas direct potable reuse faces skepticism due to the "yuck factor" associated with recycled wastewater. Studies reveal higher acceptance rates for desalination in coastal regions with water scarcity, while comprehensive public education programs significantly improve the willingness to adopt direct potable reuse. Trust in transparent water treatment technologies and rigorous safety standards plays a critical role in increasing consumer confidence for both methods.

Long-Term Sustainability and Resource Management

Desalinated water offers a reliable freshwater supply by removing salts from seawater, but it demands high energy consumption and extensive infrastructure, impacting long-term sustainability. Direct potable reuse (DPR) treats wastewater to potable standards, promoting resource efficiency by recycling water with lower energy input and reduced environmental footprint. Implementing DPR supports resilient resource management through cyclical water use, conserving natural freshwater sources and minimizing ecological disruption over time.

Future Trends in Advanced Water Reuse Technologies

Emerging advanced water reuse technologies emphasize Direct Potable Reuse (DPR) due to its lower energy demands and reduced environmental footprint compared to traditional desalination. Innovations in membrane filtration, real-time water quality monitoring, and decentralized treatment systems are enhancing DPR's safety and cost-effectiveness, positioning it as a scalable solution for urban water scarcity. Future trends prioritize integrating artificial intelligence for process optimization and hybrid systems combining desalination with reuse to maximize resource efficiency and resilience.

Related Important Terms

Brine Concentration Factor (BCF)

Desalinated water production generates a high Brine Concentration Factor (BCF), often exceeding 2.5, concentrating salts and chemicals that require careful disposal to mitigate environmental impact. Direct Potable Reuse systems typically exhibit a lower BCF, around 1.2 to 1.5, due to reduced reliance on high-salinity feedwater, enhancing sustainability by minimizing brine volume and associated treatment costs.

Reverse Osmosis Concentrate Management

Desalinated water production generates significant volumes of reverse osmosis concentrate, posing disposal challenges due to high salinity and potential contaminants. Direct potable reuse systems minimize concentrate volume by treating highly purified water before distribution, reducing environmental impact and enhancing sustainability in water management.

Advanced Oxidation Processes (AOPs)

Advanced Oxidation Processes (AOPs) play a critical role in both desalinated water production and direct potable reuse by effectively degrading organic contaminants and trace pollutants, enhancing water quality and safety. In direct potable reuse, AOPs target emerging contaminants more efficiently due to lower salinity, while in desalination, they complement membrane processes by reducing biofouling and improving overall system resilience.

Membrane Biofilm Reactor (MBfR)

Membrane Biofilm Reactor (MBfR) technology enhances water treatment by biologically removing contaminants through a biofilm on gas-permeable membranes, offering a sustainable option for Direct Potable Reuse (DPR) compared to energy-intensive desalinated water. MBfR's efficient removal of nitrogen and trace organic compounds supports safer water recycling, reducing dependence on seawater desalination and lowering environmental impact.

Microconstituent Removal

Desalinated water effectively removes a broad spectrum of microconstituents, including pharmaceuticals and trace organic compounds, through reverse osmosis and advanced membrane filtration. Direct potable reuse employs advanced oxidation processes and biofiltration, achieving comparable microconstituent removal while enabling resource recovery and lowering energy consumption.

Real-Time Water Quality Sensors

Real-time water quality sensors enhance the safety and reliability of both desalinated water and direct potable reuse by continuously monitoring parameters such as turbidity, conductivity, and microbial contaminants, enabling immediate response to contamination events. These advanced sensors improve treatment process control, ensuring consistent compliance with stringent water quality standards and optimizing resource management in potable water production.

Direct-to-Distribution Integration

Direct potable reuse (DPR) integrates treated wastewater directly into the water distribution system, minimizing energy consumption and infrastructure costs compared to desalinated water, which requires extensive desalination plants and brine disposal. DPR offers a sustainable alternative by utilizing advanced treatment technologies to ensure water quality meets safety standards before entering the potable supply, enhancing water security in urban areas facing limited freshwater sources.

Indirect Potable Reuse (IPR) Bridging

Indirect Potable Reuse (IPR) serves as a critical bridging strategy between desalinated water production and direct potable reuse by introducing advanced treatment processes that enhance water quality through environmental buffer zones, ensuring safety and public acceptance. IPR leverages natural filtration and microbial attenuation in subsurface or surface storage, optimizing contaminant removal and providing a robust framework for integrating reclaimed water into potable supply systems.

Desal Brine Valorization

Desal brine valorization transforms hypersaline waste from desalination plants into valuable resources such as minerals, chemicals, and energy, reducing environmental impact and improving sustainability. Compared to direct potable reuse, which recycles treated wastewater for drinking, brine valorization addresses the critical challenge of brine disposal and contributes to circular economy goals in water management.

Trace Organics in DPR (Direct Potable Reuse)

Trace organics in Direct Potable Reuse (DPR) systems, including pharmaceuticals, personal care products, and endocrine-disrupting compounds, pose significant treatment challenges that require advanced multi-barrier processes such as reverse osmosis and advanced oxidation to ensure water safety. Unlike desalinated water, which primarily deals with inorganic salts, DPR must address complex trace organic contaminants to prevent potential health risks and maintain regulatory compliance.

Desalinated Water vs Direct Potable Reuse Infographic

industrydif.com

industrydif.com