Sedimentation relies on gravity to separate suspended particles from water by allowing them to settle naturally over time. Ballasted flocculation enhances this process by adding heavy particles, such as sand or magnetite, to increase floc weight and accelerate settling rates. This method improves clarity and efficiency in water treatment, making it suitable for higher turbidity levels and faster processing times.

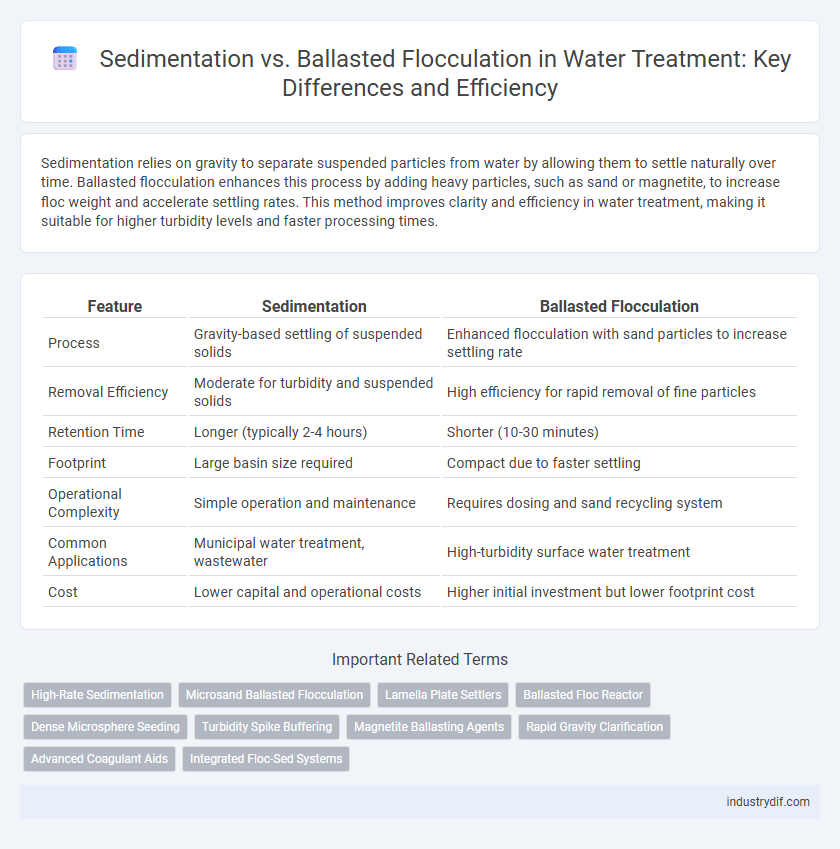

Table of Comparison

| Feature | Sedimentation | Ballasted Flocculation |

|---|---|---|

| Process | Gravity-based settling of suspended solids | Enhanced flocculation with sand particles to increase settling rate |

| Removal Efficiency | Moderate for turbidity and suspended solids | High efficiency for rapid removal of fine particles |

| Retention Time | Longer (typically 2-4 hours) | Shorter (10-30 minutes) |

| Footprint | Large basin size required | Compact due to faster settling |

| Operational Complexity | Simple operation and maintenance | Requires dosing and sand recycling system |

| Common Applications | Municipal water treatment, wastewater | High-turbidity surface water treatment |

| Cost | Lower capital and operational costs | Higher initial investment but lower footprint cost |

Introduction to Water Treatment Processes

Sedimentation in water treatment relies on gravity to remove suspended solids by allowing particles to settle over time, effectively clarifying water in primary treatment stages. Ballasted flocculation enhances this process by adding dense media such as sand or microsand to flocculate particles rapidly, significantly accelerating settling rates and improving turbidity removal efficiency. These techniques are integral in water treatment plants to optimize solid-liquid separation and ensure high-quality potable water production.

Overview of Sedimentation

Sedimentation is a gravity-driven process that separates suspended solids from water by allowing particles to settle naturally over time in a quiescent basin. This method effectively reduces turbidity and particulate matter, improving water clarity before further treatment stages. Sedimentation performance depends on factors like particle size, density, and hydraulic retention time, making it a critical step in conventional water treatment systems.

Fundamentals of Ballasted Flocculation

Ballasted flocculation enhances sedimentation by integrating heavy microsand particles that accelerate floc formation and improve settling rates in water treatment. This process increases the efficiency of contaminant removal by promoting rapid aggregation of suspended solids, which sediment faster compared to conventional sedimentation alone. Optimizing ballast concentration and mixing conditions is crucial for maximizing floc density and ensuring effective clarification in wastewater and drinking water plants.

Key Differences Between Sedimentation and Ballasted Flocculation

Sedimentation relies on gravity to settle suspended particles naturally, whereas ballasted flocculation enhances particle aggregation by adding a ballast material, typically microsand, to increase settling velocity. The key difference lies in efficiency; ballasted flocculation achieves faster and more compact sludge settling compared to conventional sedimentation, making it ideal for high-rate water treatment processes. Additionally, ballasted flocculation reduces the footprint of treatment tanks and improves overall removal of fine particulates and organic matter.

Process Efficiency and Removal Rates

Sedimentation relies on gravity to settle suspended solids, achieving moderate removal rates typically around 50-70%, whereas ballasted flocculation enhances process efficiency by accelerating floc formation with microsand or magnetite, reaching removal rates exceeding 90%. The increased settling velocity in ballasted flocculation significantly reduces retention time, enabling higher throughput in water treatment facilities. This technique also improves the removal of fine particles and organic matter, surpassing traditional sedimentation in both efficiency and effectiveness.

Chemical Usage and Operational Costs

Sedimentation processes typically require minimal chemical usage, relying on gravity to separate solids, resulting in lower operational costs compared to ballasted flocculation. Ballasted flocculation involves higher chemical dosages, including coagulants and ballast materials like microsand, which increase both chemical consumption and maintenance expenses. Operational costs for ballasted flocculation are elevated due to increased energy demands for mixing and equipment requirements to handle heavier sludge volumes.

Applicability to Various Water Qualities

Sedimentation efficiently treats water with relatively low turbidity and suspended solids, making it suitable for clear surface water or pre-treated wastewater. Ballasted flocculation excels in handling high-turbidity water and complex wastewater by rapidly aggregating fine particles using microsand or magnetite, offering enhanced performance in diverse water qualities. This method provides greater adaptability and faster settling rates across varying source water conditions compared to conventional sedimentation.

Infrastructure and Space Requirements

Sedimentation requires large, open basins with significant land area to allow particles to settle naturally, making it space-intensive and demanding substantial infrastructure investment. Ballasted flocculation employs microsand or other ballast materials to accelerate particle settling in smaller tanks, reducing footprint and lowering infrastructure costs compared to traditional sedimentation. The increased efficiency of ballasted flocculation allows treatment plants to achieve higher throughput in compact spaces, optimizing urban water treatment facility design.

Environmental Impact and Sustainability

Sedimentation typically consumes less energy but requires larger land areas, potentially disrupting local ecosystems, whereas ballasted flocculation accelerates particle settling with reduced footprint and lower chemical usage, enhancing sustainability. Ballasted flocculation's rapid treatment reduces sludge volume and minimizes the environmental burden of sludge disposal compared to sedimentation. Optimizing these methods can significantly impact water treatment's ecological footprint, promoting resource-efficient and environmentally friendly practices.

Selecting the Right Treatment for Your Facility

Sedimentation effectively removes suspended solids by allowing particles to settle naturally, making it ideal for facilities with moderate contaminant loads and sufficient retention time. Ballasted flocculation enhances settling by adding dense microsand particles, accelerating floc formation and improving removal efficiency in high-turbidity or high-flow environments. Selecting the right treatment depends on factors like influent water quality, facility size, and treatment goals, ensuring optimal performance and cost-effectiveness in water purification processes.

Related Important Terms

High-Rate Sedimentation

High-rate sedimentation systems achieve rapid solids removal by increasing hydraulic loading rates, but their efficiency often decreases with smaller particle sizes, making ballasted flocculation advantageous as it accelerates particle aggregation through the addition of microsand or ballast materials. Ballasted flocculation enhances settling rates up to 10 times faster than conventional sedimentation, optimizing treatment capacity in water and wastewater plants by improving turbidity reduction and floc density.

Microsand Ballasted Flocculation

Microsand ballasted flocculation enhances sedimentation processes by using fine sand particles as ballast to increase floc density and settling velocity, improving removal of suspended solids and turbidity. This method offers faster clarifier performance and can reduce footprint and chemical consumption compared to conventional sedimentation.

Lamella Plate Settlers

Lamella plate settlers enhance sedimentation efficiency by providing an increased surface area for particle settling, reducing the tank footprint compared to traditional gravity sedimentation. Ballasted flocculation accelerates particle aggregation using high-density media, achieving faster settling rates but often requiring complex equipment and higher energy input than lamella sedimentation systems.

Ballasted Floc Reactor

Ballasted Floc Reactors (BFR) enhance sedimentation by using micro-sand as a ballast agent to accelerate floc formation and settling velocity, reducing retention time and footprint for water treatment plants. This technology improves removal efficiency of suspended solids and turbidity compared to conventional sedimentation, making it ideal for treating high-turbidity surface water and industrial wastewater.

Dense Microsphere Seeding

Dense microsphere seeding in ballasted flocculation significantly enhances sedimentation rates by increasing particle weight and promoting rapid aggregate formation, outperforming conventional sedimentation processes that rely solely on gravity settling. This method improves water treatment efficiency by enabling faster removal of suspended solids and reducing footprint requirements for clarifiers.

Turbidity Spike Buffering

Sedimentation effectively reduces turbidity by allowing suspended particles to settle naturally, but it may cause a brief turbidity spike due to resuspension during discharge, whereas ballasted flocculation employs denser media to accelerate particle aggregation and settling, providing superior turbidity spike buffering and minimizing flare-ups. The enhanced settling velocity in ballasted flocculation systems results in more stable effluent clarity, significantly improving turbidity control in water treatment processes.

Magnetite Ballasting Agents

Magnetite ballasting agents significantly enhance ballasted flocculation by accelerating sedimentation rates through increased floc density and rapid settling, outperforming traditional sedimentation methods. The high magnetic susceptibility of magnetite allows for efficient separation and recovery, optimizing wastewater treatment processes by reducing retention time and improving removal of suspended solids.

Rapid Gravity Clarification

Rapid gravity clarification optimizes water treatment by combining sedimentation and ballasted flocculation processes to enhance particle removal and settling efficiency. Ballasted flocculation accelerates sedimentation rates by using heavy particles as ballast, significantly reducing clarifier footprint and improving turbidity removal compared to conventional sedimentation alone.

Advanced Coagulant Aids

Sedimentation relies on gravity to separate suspended solids, while ballasted flocculation enhances particle removal by adding ballast materials to accelerate floc formation. Advanced coagulant aids improve both processes by promoting rapid aggregation and stronger floc structures, increasing overall treatment efficiency and enabling higher throughput in water treatment plants.

Integrated Floc-Sed Systems

Integrated floc-sed systems combine sedimentation and ballasted flocculation to enhance solid-liquid separation efficiency in water treatment by accelerating settling rates through denser floc particles formed with ballast materials like sand or magnetite. These systems reduce tank size requirements and improve contaminant removal, making them ideal for high-throughput wastewater and drinking water applications.

Sedimentation vs Ballasted Flocculation Infographic

industrydif.com

industrydif.com