Big tractors provide powerful and reliable performance for large-scale farming, enabling efficient tilling and harvesting over vast fields. Autonomous tractors leverage advanced sensors and AI to optimize precision farming, reducing labor costs and minimizing human error. Choosing between them depends on farm size, budget, and the desired level of technological integration.

Table of Comparison

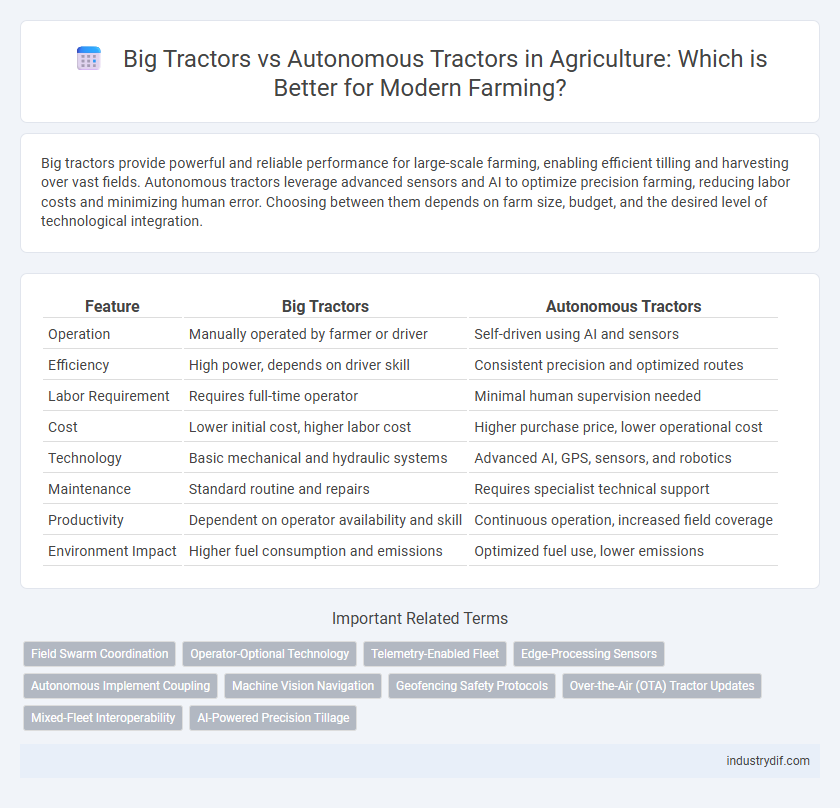

| Feature | Big Tractors | Autonomous Tractors |

|---|---|---|

| Operation | Manually operated by farmer or driver | Self-driven using AI and sensors |

| Efficiency | High power, depends on driver skill | Consistent precision and optimized routes |

| Labor Requirement | Requires full-time operator | Minimal human supervision needed |

| Cost | Lower initial cost, higher labor cost | Higher purchase price, lower operational cost |

| Technology | Basic mechanical and hydraulic systems | Advanced AI, GPS, sensors, and robotics |

| Maintenance | Standard routine and repairs | Requires specialist technical support |

| Productivity | Dependent on operator availability and skill | Continuous operation, increased field coverage |

| Environment Impact | Higher fuel consumption and emissions | Optimized fuel use, lower emissions |

Overview of Big Tractors and Autonomous Tractors

Big tractors dominate traditional farming with powerful engines exceeding 400 horsepower and advanced hydraulics for heavy-duty tasks across extensive acreage. Autonomous tractors leverage GPS, machine learning, and sensor technology to perform precision agriculture, reducing labor costs and increasing operational efficiency. Both types enhance productivity, but autonomous tractors excel in data-driven crop management and real-time field analysis.

Key Features Comparison: Human-Operated vs Autonomous

Big tractors feature powerful engines, manual controls, and require skilled operators to manage complex tasks, offering flexibility in various terrains and crop types. Autonomous tractors utilize GPS, AI, and sensor technology to perform precision farming with minimal human intervention, enhancing efficiency, reducing labor costs, and enabling 24/7 operation. Key distinctions include human decision-making adaptability in big tractors versus data-driven automation and consistent performance in autonomous models.

Technology Integration in Modern Tractors

Modern tractors integrate advanced GPS-guided systems and AI-driven automation to enhance precision in farming tasks. Big tractors offer robust power and versatility for large-scale operations, while autonomous tractors utilize sensors and real-time data analytics to optimize efficiency and reduce human labor. The convergence of IoT technology and machine learning propels both types of tractors toward smarter, more sustainable agricultural practices.

Operational Efficiency: Speed and Precision Metrics

Big tractors equipped with powerful engines deliver high-speed field coverage, yet autonomous tractors optimize operational efficiency through precise GPS-guided navigation, reducing overlap and fuel consumption. Autonomous tractors achieve consistent precision within centimeters, enabling accurate planting and spraying that enhances crop yields and minimizes waste. Speed in autonomous models is balanced with precision algorithms, ensuring maximum productivity without sacrificing the accuracy critical for modern agricultural practices.

Labor and Workforce Implications

Big tractors require extensive labor for operation, maintenance, and transportation, demanding skilled drivers and support staff, which increases workforce costs and complexity. Autonomous tractors reduce the need for direct human involvement, enabling precision farming with fewer workers, thereby alleviating labor shortages and minimizing human error. The shift towards autonomous machinery reshapes agricultural labor dynamics, emphasizing technical skills for oversight and system management over manual operation.

Cost Analysis: Initial Investment and ROI

Big tractors typically require a high initial investment ranging from $150,000 to $500,000, with operational costs including fuel, maintenance, and labor, affecting overall ROI. Autonomous tractors, though often more expensive upfront at $200,000 to $600,000, reduce labor costs significantly and optimize fuel use, potentially leading to faster ROI in large-scale farming operations. Analyzing long-term savings in labor, precision farming efficiencies, and maintenance expenses is crucial for farmers to determine the most cost-effective choice between traditional big tractors and autonomous models.

Safety and Risk Management Considerations

Big tractors offer robust power and durability but pose higher risks of operator fatigue and accident potential due to their size and manual control. Autonomous tractors enhance safety by reducing human error and enabling precise, sensor-driven operations that minimize collision risks and soil compaction. Implementing advanced safety protocols and integrating real-time monitoring systems are critical for effective risk management in both technologies.

Sustainability and Environmental Impact

Big tractors contribute to soil compaction and higher fossil fuel consumption, increasing greenhouse gas emissions and reducing long-term soil health. Autonomous tractors leverage precision agriculture technology, optimizing fuel use and minimizing overlap, which reduces emissions and enhances sustainability in crop management. The integration of autonomous systems promotes efficient resource use, supporting environmental conservation and sustainable farming practices.

Adoption Barriers and Industry Challenges

Big tractors face adoption barriers such as high initial costs, limited maneuverability in smaller fields, and dependence on skilled operators, while autonomous tractors encounter challenges including advanced sensor integration, software reliability, and data management complexities. Both face industry hurdles like infrastructure adaptation, regulatory compliance, and farmer trust in technology efficacy. Overcoming these barriers requires targeted investment in training, technology standardization, and scalable integration solutions.

Future Trends in Tractor Technology

Future trends in tractor technology emphasize the integration of autonomous tractors equipped with precision GPS and AI-driven systems, enhancing efficiency and reducing labor costs on large farms. Big tractors continue to evolve with increased horsepower and fuel efficiency but face competition from smaller, autonomous units capable of continuous operation with minimal human intervention. The shift towards sustainable agriculture accelerates the adoption of electric autonomous tractors, promising reduced emissions and smarter resource management.

Related Important Terms

Field Swarm Coordination

Big tractors offer high horsepower and capacity for large-scale farming but lack the precision and flexibility of autonomous tractors, which excel in field swarm coordination by communicating in real-time to optimize planting, irrigation, and harvesting patterns. Autonomous tractor swarms reduce soil compaction and fuel consumption while increasing operational efficiency through synchronized movements tailored to specific crop and field conditions.

Operator-Optional Technology

Big tractors offer high horsepower and versatility for large-scale farming but require skilled operators, whereas autonomous tractors leverage operator-optional technology to perform precise field tasks with minimal human intervention, enhancing efficiency and reducing labor costs. Advances in GPS-guided steering, machine learning, and sensor integration enable autonomous tractors to optimize planting, spraying, and harvesting, transforming modern agricultural practices.

Telemetry-Enabled Fleet

Telemetry-enabled fleets in agriculture enhance operational efficiency by providing real-time data on big tractors' performance and autonomous tractors' activities. This technology optimizes fleet management, reduces downtime, and improves precision farming through continuous monitoring and predictive maintenance.

Edge-Processing Sensors

Big tractors equipped with advanced edge-processing sensors enable real-time data analysis for precision farming, reducing latency and improving decision-making on the field. Autonomous tractors leverage these smart sensors to enhance operational efficiency, minimizing human intervention while optimizing resource use and crop yields.

Autonomous Implement Coupling

Autonomous implement coupling enhances the efficiency of big tractors by enabling precise, hands-free attachment and adjustment of farming equipment, reducing downtime and operator fatigue. This technology leverages advanced sensors and AI to optimize implement performance, offering greater accuracy and consistent productivity compared to traditional manual coupling methods.

Machine Vision Navigation

Big tractors equipped with traditional GPS navigation offer powerful performance but lack precise environmental awareness, limiting efficiency in complex terrains. Autonomous tractors utilize advanced machine vision navigation systems, enabling real-time obstacle detection and accurate path planning to optimize field operations and reduce labor costs.

Geofencing Safety Protocols

Big tractors utilize geofencing safety protocols to establish virtual boundaries that prevent operation outside designated areas, minimizing risks to workers and crops. Autonomous tractors employ advanced geofencing integrated with GPS and sensor technology to dynamically adjust routes and halt movement when crossing restricted zones, enhancing precision and safety in agricultural operations.

Over-the-Air (OTA) Tractor Updates

Big tractors benefit from comprehensive Over-the-Air (OTA) updates that enhance engine performance and heavy-duty functionalities, ensuring sustained power and reliability in large-scale farming operations. Autonomous tractors leverage OTA updates to improve AI-driven navigation systems and sensor accuracy, optimizing precision agriculture and reducing the need for manual intervention in field management.

Mixed-Fleet Interoperability

Mixed-fleet interoperability between big tractors and autonomous tractors enhances farm efficiency by integrating advanced sensor systems and real-time data sharing through IoT platforms, enabling seamless coordination in planting, harvesting, and field management. Leveraging GPS-guided navigation and precision agriculture technologies, these hybrid fleets optimize resource use, reduce downtime, and increase crop yields across diverse agricultural operations.

AI-Powered Precision Tillage

AI-powered precision tillage enhances soil health and crop yields by using advanced sensors and machine learning algorithms to optimize depth and spacing, minimizing compaction and maximizing nutrient absorption. Autonomous tractors equipped with these technologies outperform traditional big tractors by enabling real-time decision-making, reducing fuel consumption, and improving operational efficiency in large-scale farming.

Big tractors vs Autonomous tractors Infographic

industrydif.com

industrydif.com