Conventional substations rely on hardwired connections and electromechanical relays for monitoring and control, which can limit scalability and increase maintenance requirements. Digital substations utilize advanced communication protocols and intelligent electronic devices to enhance real-time data analysis, operational efficiency, and remote control capabilities. This transition enables improved grid reliability and more efficient integration of renewable energy sources.

Table of Comparison

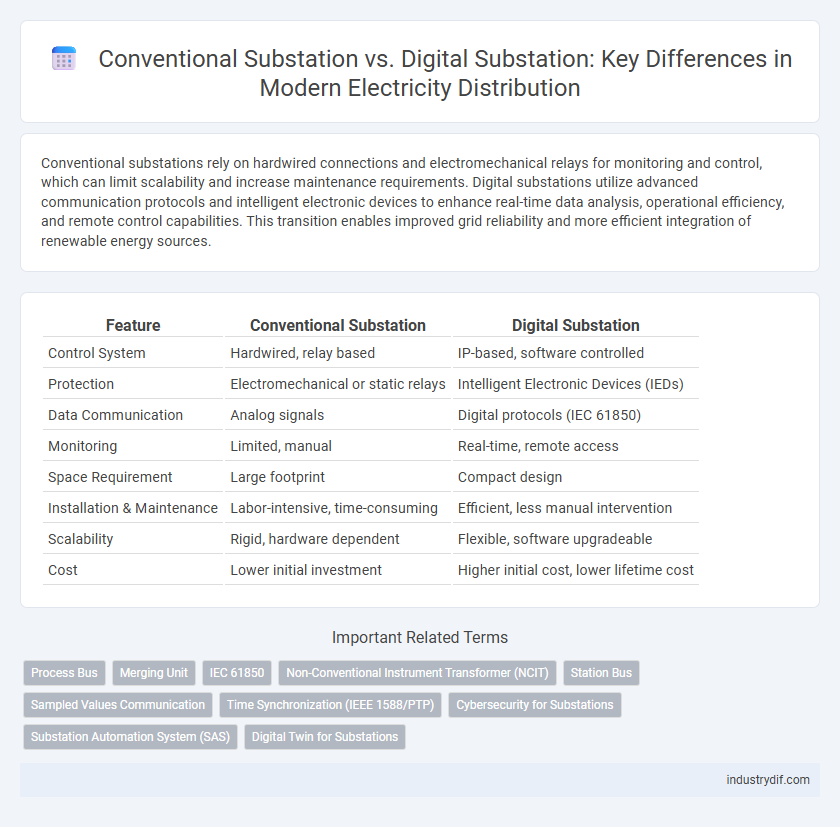

| Feature | Conventional Substation | Digital Substation |

|---|---|---|

| Control System | Hardwired, relay based | IP-based, software controlled |

| Protection | Electromechanical or static relays | Intelligent Electronic Devices (IEDs) |

| Data Communication | Analog signals | Digital protocols (IEC 61850) |

| Monitoring | Limited, manual | Real-time, remote access |

| Space Requirement | Large footprint | Compact design |

| Installation & Maintenance | Labor-intensive, time-consuming | Efficient, less manual intervention |

| Scalability | Rigid, hardware dependent | Flexible, software upgradeable |

| Cost | Lower initial investment | Higher initial cost, lower lifetime cost |

Overview of Conventional and Digital Substations

Conventional substations rely on analog equipment and hardwired control systems to manage electrical power flow and protection, often requiring extensive physical space and manual maintenance. Digital substations integrate advanced communication protocols, intelligent electronic devices (IEDs), and real-time data processing to enhance operational efficiency, fault detection, and remote monitoring capabilities. The transition to digital technology enables improved scalability, cybersecurity, and faster response times compared to traditional analog systems.

Key Components of Conventional Substations

Conventional substations primarily consist of transformers, circuit breakers, disconnect switches, and protective relays that operate through electromechanical or analog devices. These key components are physically interconnected via copper wiring and require extensive manual control panels for monitoring and operation. The reliance on local control and hardwired connections limits automation and real-time data acquisition compared to digital substations.

Key Components of Digital Substations

Digital substations integrate intelligent electronic devices (IEDs), process bus, and digital relays to enhance operational efficiency and reliability. These key components enable real-time data acquisition, advanced fault detection, and remote control capabilities, contrasting with conventional substations reliant on analog equipment and hard-wired connections. The adoption of Ethernet-based communication networks and innovative sensors further optimizes monitoring and maintenance processes in digital substations.

Major Differences Between Conventional and Digital Substations

Conventional substations rely on hardwired relay protection, manual monitoring, and analog signal processing, which limits real-time data access and integration capabilities. Digital substations utilize intelligent electronic devices (IEDs), digital communication protocols such as IEC 61850, and advanced automation for enhanced monitoring, control, and fault detection. This shift results in improved operational efficiency, remote accessibility, and reduced maintenance costs compared to traditional setups.

Advantages of Digital Substations Over Conventional Designs

Digital substations enhance operational efficiency by integrating advanced communication protocols, enabling real-time data monitoring and remote control, which significantly reduce downtime and maintenance costs. Their modular design and intelligent electronic devices (IEDs) improve system flexibility, scalability, and fault diagnosis accuracy compared to conventional substations. Enhanced cybersecurity features and reduced physical wiring further contribute to improved reliability and safety in digital substation operations.

Challenges in Upgrading from Conventional to Digital Substations

Upgrading from conventional substations to digital substations presents challenges such as high initial investment costs for digital equipment and communication infrastructure. Integration complexity arises due to legacy systems requiring compatibility with modern Intelligent Electronic Devices (IEDs) and protocols like IEC 61850. Cybersecurity risks increase as digital substations rely on networked communication, necessitating robust protection mechanisms against potential cyber threats.

Protection and Control Systems Comparison

Conventional substations rely on electromechanical and hardwired protection and control systems, which often involve bulky equipment and limited real-time monitoring capabilities. Digital substations utilize advanced Intelligent Electronic Devices (IEDs) and Ethernet-based communication protocols, enabling faster fault detection, precise control, and improved system reliability. This transition enhances operational efficiency by integrating protection, automation, and remote diagnostics within a unified digital framework.

Communication Protocols in Substations: Analog vs Digital

Conventional substations primarily use analog communication protocols such as 4-20mA signals and hardwired relays which limit real-time data exchange and increase maintenance complexity. Digital substations employ advanced communication protocols like IEC 61850, enabling seamless Ethernet-based data transmission that enhances interoperability, reduces wiring costs, and supports intelligent automation. The transition from analog to digital protocols significantly improves operational efficiency, fault detection accuracy, and overall substation reliability.

Cost and Maintenance Implications

Conventional substations incur higher costs due to extensive wiring, bulky equipment, and frequent maintenance requirements driven by aging mechanical components. Digital substations reduce expenditures through modular designs, efficient fault detection, and remote monitoring capabilities that lower downtime and labor expenses. The transition to digital systems enhances operational efficiency, minimizing long-term maintenance costs despite initial investment.

Future Trends in Substation Technology

Future trends in substation technology emphasize the transition from conventional substations, which rely on analog equipment and manual controls, to digital substations featuring intelligent electronic devices (IEDs) and real-time data communication. Digital substations leverage advanced protocols like IEC 61850 for enhanced interoperability, predictive maintenance, and remote monitoring, leading to increased grid reliability and efficiency. Integration of IoT, artificial intelligence, and edge computing further revolutionizes substation automation, enabling faster fault detection, adaptive control, and smarter asset management.

Related Important Terms

Process Bus

The process bus in a digital substation utilizes fiber-optic communication to transmit real-time data from intelligent electronic devices (IEDs), enhancing accuracy and reducing electromagnetic interference compared to conventional substations that rely on separate copper wiring and hardwired connections. This digital integration streamlines protection, control, and monitoring processes, resulting in improved operational efficiency and simplified maintenance.

Merging Unit

Merging units in digital substations convert analog signals from current and voltage transformers into digital data streams, enabling real-time monitoring and enhanced protection schemes, unlike conventional substations that rely on hardwired connections and analog relays. This transition improves data accuracy, reduces wiring complexity, and supports IEC 61850 communication protocols for interoperability and system integration.

IEC 61850

Conventional substations rely on hardwired control systems, whereas digital substations implement IEC 61850 standards for enhanced interoperability, real-time communication, and efficient data management. IEC 61850 enables digital substations to achieve higher automation levels, improved fault diagnosis, and seamless integration with modern smart grid technologies.

Non-Conventional Instrument Transformer (NCIT)

Non-Conventional Instrument Transformers (NCIT) in digital substations offer enhanced accuracy, compactness, and reduced maintenance compared to conventional electromagnetic transformers used in traditional substations. NCITs leverage fiber optic and electronic technologies to provide high-fidelity measurements, enabling real-time monitoring and improved protection schemes in modern power systems.

Station Bus

Conventional substations use hardwired copper connections for station bus communication, limiting data transfer speed and flexibility, whereas digital substations employ fiber-optic station buses that enable high-speed, secure, and real-time data exchange for improved protection and control systems. This transition enhances operational efficiency, scalability, and integration with smart grid technologies.

Sampled Values Communication

Conventional substations rely on analog signals and hardwired connections for sample data transmission, often resulting in limited scalability and slower response times. Digital substations utilize Sampled Values communication over IEC 61850 protocol, enabling precise, real-time data exchange with enhanced accuracy, interoperability, and reduced wiring complexity.

Time Synchronization (IEEE 1588/PTP)

Conventional substations rely on traditional methods for time synchronization, often facing challenges in accuracy and latency, whereas digital substations utilize IEEE 1588 Precision Time Protocol (PTP) to achieve high-precision, low-latency synchronization essential for real-time protection and control. Implementing PTP in digital substations enhances data accuracy, improves system reliability, and facilitates advanced automation and monitoring capabilities.

Cybersecurity for Substations

Conventional substations rely on outdated protection systems and isolated architectures, making them more vulnerable to cyber threats and unauthorized access. Digital substations integrate advanced communication protocols and real-time monitoring, enhancing cybersecurity through encrypted data transmission and enhanced intrusion detection systems.

Substation Automation System (SAS)

Conventional substations rely on legacy hardwired connections and analog relays for Substation Automation Systems (SAS), limiting real-time data acquisition and remote control capabilities. Digital substations employ advanced SAS with intelligent electronic devices (IEDs) and standardized communication protocols like IEC 61850, enhancing operational efficiency, fault detection, and interoperability.

Digital Twin for Substations

Digital substations leverage digital twin technology to create real-time virtual replicas of physical substations, enabling enhanced monitoring, predictive maintenance, and optimized asset management. Unlike conventional substations that rely on analog systems, digital substations integrate IoT sensors and advanced analytics to improve operational efficiency and fault detection accuracy.

Conventional Substation vs Digital Substation Infographic

industrydif.com

industrydif.com