Electrical substations traditionally manage power distribution through analog equipment, relying on manual controls and physical wiring, which can limit flexibility and increase maintenance demands. Digital substations integrate intelligent electronic devices (IEDs) and communication networks to enhance real-time monitoring, automation, and remote control capabilities. This shift improves operational efficiency, reduces downtime, and supports smart grid advancements.

Table of Comparison

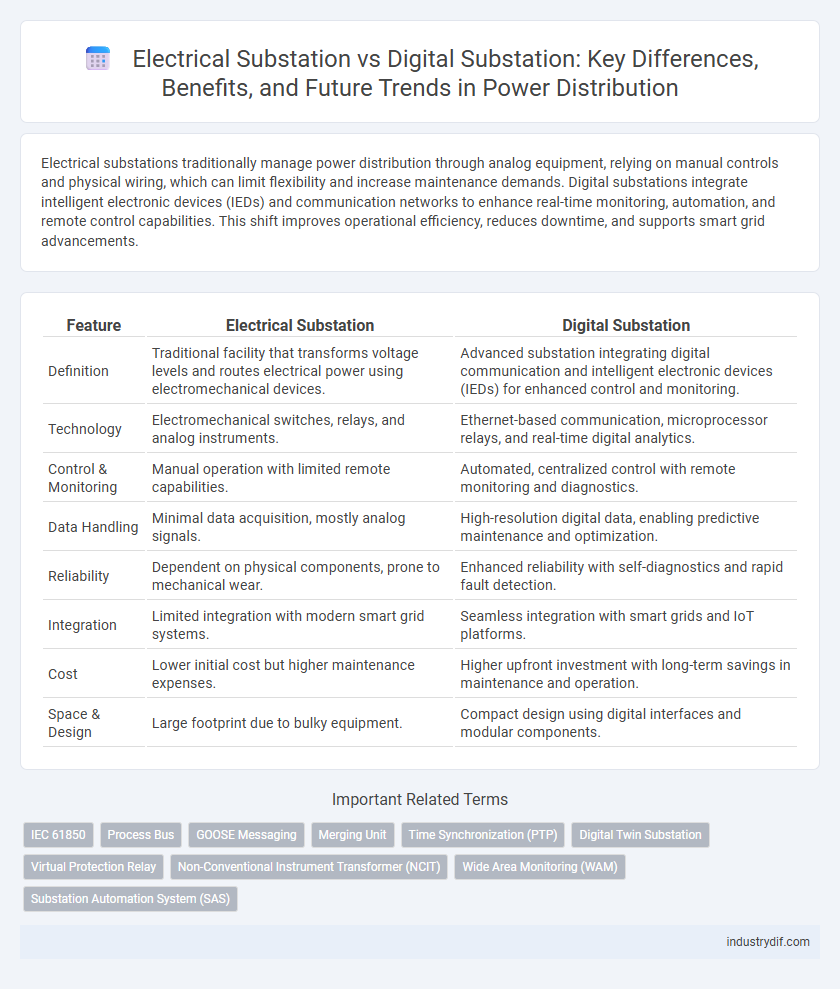

| Feature | Electrical Substation | Digital Substation |

|---|---|---|

| Definition | Traditional facility that transforms voltage levels and routes electrical power using electromechanical devices. | Advanced substation integrating digital communication and intelligent electronic devices (IEDs) for enhanced control and monitoring. |

| Technology | Electromechanical switches, relays, and analog instruments. | Ethernet-based communication, microprocessor relays, and real-time digital analytics. |

| Control & Monitoring | Manual operation with limited remote capabilities. | Automated, centralized control with remote monitoring and diagnostics. |

| Data Handling | Minimal data acquisition, mostly analog signals. | High-resolution digital data, enabling predictive maintenance and optimization. |

| Reliability | Dependent on physical components, prone to mechanical wear. | Enhanced reliability with self-diagnostics and rapid fault detection. |

| Integration | Limited integration with modern smart grid systems. | Seamless integration with smart grids and IoT platforms. |

| Cost | Lower initial cost but higher maintenance expenses. | Higher upfront investment with long-term savings in maintenance and operation. |

| Space & Design | Large footprint due to bulky equipment. | Compact design using digital interfaces and modular components. |

Introduction to Electrical and Digital Substations

Electrical substations are critical components of power systems, serving as nodes where voltage is transformed, controlled, and routed to ensure efficient electricity distribution. Digital substations incorporate advanced communication technologies and intelligent electronic devices (IEDs) to improve automation, monitoring, and fault detection capabilities. The transition from traditional electrical substations to digital ones enhances operational efficiency, reliability, and integration with smart grid infrastructures.

Key Components of Traditional Electrical Substations

Traditional electrical substations primarily consist of transformers, circuit breakers, isolators, and busbars, which manage voltage regulation and ensure safe power distribution. Instrument transformers like current and voltage transformers provide essential measurement and protective functions. Control panels and relay systems facilitate manual operation and fault detection, distinguishing them from the automated components found in digital substations.

Defining Digital Substations: Core Features

Digital substations integrate advanced communication protocols and intelligent electronic devices (IEDs) to enhance real-time data monitoring and control, replacing traditional hard-wired systems. Key features include IEC 61850 standard compliance, Ethernet-based communication, and enhanced automation capabilities for improved efficiency and reliability. These core attributes enable seamless integration with smart grids, predictive maintenance, and remote operation.

Automation and Communication Technologies

Traditional electrical substations rely on analog instruments and point-to-point wiring for automation, limiting speed and flexibility in control and monitoring. Digital substations employ advanced communication protocols such as IEC 61850, enabling real-time data exchange, remote control, and enhanced interoperability between intelligent electronic devices (IEDs). Integration of automation technologies like distributed control systems and digital relays in digital substations reduces operational costs, improves fault detection, and enhances overall grid reliability.

Monitoring, Control, and Protection Systems Comparison

Traditional electrical substations rely on analog monitoring, control, and protection systems with separate, hardwired control panels and electromechanical relays, limiting real-time data acquisition and remote accessibility. Digital substations integrate intelligent electronic devices (IEDs) and use Ethernet-based communication protocols like IEC 61850, enabling high-speed data transfer, enhanced automation, and centralized monitoring for improved operational efficiency. This modernization supports more accurate fault detection, adaptive protection schemes, and easier integration with smart grid technologies, significantly enhancing reliability and system flexibility.

Reliability and Operational Efficiency

Electrical substations rely on conventional equipment and manual monitoring, which can lead to slower fault detection and higher maintenance costs, impacting overall reliability. Digital substations use intelligent electronic devices (IEDs) and advanced communication protocols like IEC 61850, enabling real-time data exchange, faster fault isolation, and predictive maintenance, significantly enhancing operational efficiency. This transition improves system resilience and reduces downtime, making digital substations a more reliable and cost-effective solution in modern power grids.

Integration with Smart Grids

Electrical substations serve as crucial nodes for transforming voltage and distributing power, relying primarily on traditional electromechanical equipment. Digital substations utilize advanced IEDs (Intelligent Electronic Devices) and IEC 61850 protocols to enable real-time data communication and automation, significantly enhancing integration with smart grids. This integration facilitates improved grid reliability, efficient fault management, and seamless interoperability within modern smart grid ecosystems.

Cost Implications: Installation and Maintenance

Traditional electrical substations require substantial capital investment in physical infrastructure, including transformers, circuit breakers, and control rooms, leading to higher installation costs. Digital substations reduce these costs by employing advanced automation, communication networks, and intelligent electronic devices (IEDs), which streamline installation and allow for remote monitoring and diagnostics. Maintenance expenses decrease significantly in digital substations due to predictive maintenance capabilities and reduced need for manual inspections, resulting in lower operational expenditures over time.

Cybersecurity Challenges and Solutions

Traditional electrical substations face increasing cybersecurity challenges due to outdated protocols and limited monitoring capabilities, making them vulnerable to cyberattacks that could disrupt grid stability. Digital substations integrate advanced communication networks, intelligent electronic devices (IEDs), and real-time data analytics, enhancing threat detection and response but also introducing risks related to software vulnerabilities and network intrusions. Implementing robust cybersecurity frameworks, such as IEC 62443 standards, multi-layer encryption, and continuous network monitoring, is essential to safeguard digital substations against evolving cyber threats while ensuring reliable power distribution.

Future Trends in Substation Technology

Digital substations leverage advanced communication protocols such as IEC 61850 to enable real-time data exchange and enhanced automation, driving operational efficiency beyond traditional electrical substations. The integration of IoT sensors, AI-driven analytics, and cloud-based monitoring systems is accelerating the evolution toward smarter, more resilient grid infrastructure. Future trends emphasize cyber-physical security enhancements and predictive maintenance capabilities to support sustainable and reliable electricity distribution.

Related Important Terms

IEC 61850

Electrical substations traditionally rely on hardwired controls and analog devices, while digital substations leverage IEC 61850 standards to enable interoperable, real-time communication between Intelligent Electronic Devices (IEDs), enhancing automation, monitoring, and control. IEC 61850 facilitates streamlined data exchange and improved system reliability by standardizing communication protocols, enabling seamless integration of protection, control, and measurement functions within digital substations.

Process Bus

A digital substation utilizes a process bus to replace traditional copper wiring, enabling real-time data transmission through fiber-optic cables, which enhances communication speed and reduces electromagnetic interference. This innovation in electrical substations improves system reliability, simplifies maintenance, and supports advanced automation for efficient grid management.

GOOSE Messaging

GOOSE messaging in digital substations enables real-time, high-speed communication between Intelligent Electronic Devices (IEDs) by using Ethernet-based protocols, enhancing automation and operational efficiency compared to traditional electrical substations that rely on slower, point-to-point hardwired connections. This transition to digital substations significantly improves fault detection, system reliability, and reduces infrastructure complexity, supporting smart grid advancements.

Merging Unit

Electrical substations utilize traditional analog merging units to aggregate signals from instrument transformers, whereas digital substations employ advanced digital merging units that convert primary equipment data into high-speed sampled values for enhanced real-time monitoring and protection. Digital merging units support IEC 61850-9-2 communication protocol, enabling seamless integration with intelligent electronic devices (IEDs) and facilitating efficient data exchange and automation in smart grid systems.

Time Synchronization (PTP)

Traditional electrical substations rely on analog time synchronization methods, which can introduce latency and reduce the accuracy of data timestamps. Digital substations implement Precision Time Protocol (PTP) to provide high-precision synchronization, enhancing real-time monitoring, fault analysis, and automation accuracy across the power grid.

Digital Twin Substation

Digital twin substations leverage real-time data and advanced simulation models to optimize the performance, maintenance, and reliability of electrical substations, providing a virtual replica for predictive analysis and operational efficiency. Unlike traditional electrical substations, digital twin technology integrates IoT sensors, AI algorithms, and cloud computing to enable proactive fault detection, energy management, and system upgrades with minimal downtime.

Virtual Protection Relay

Traditional electrical substations rely on physical protection relays for fault detection, while digital substations utilize virtual protection relays that enhance real-time data processing and remote monitoring capabilities. Virtual protection relays improve system reliability by integrating intelligent algorithms and communication protocols such as IEC 61850, enabling faster fault isolation and reducing equipment downtime.

Non-Conventional Instrument Transformer (NCIT)

Non-Conventional Instrument Transformers (NCITs) in digital substations provide enhanced accuracy, reduced maintenance, and improved safety compared to traditional electrical substations using conventional instrument transformers. NCITs enable precise real-time data acquisition and seamless integration with digital monitoring systems, optimizing power grid reliability and operational efficiency.

Wide Area Monitoring (WAM)

Electrical substations traditionally rely on localized monitoring systems, whereas digital substations integrate Wide Area Monitoring (WAM) technology to enhance grid visibility and real-time data acquisition across extensive geographic areas. WAM enables rapid fault detection, improved situational awareness, and proactive grid management by utilizing synchronized phasor measurement units (PMUs) and advanced communication networks within digital substations.

Substation Automation System (SAS)

Electrical substations equipped with traditional Substation Automation Systems (SAS) rely on physical relays and manual controls, whereas digital substations integrate Intelligent Electronic Devices (IEDs) and digital communication protocols like IEC 61850 to enable real-time data exchange, remote monitoring, and enhanced control capabilities. This transformation significantly improves operational efficiency, fault detection accuracy, and system reliability by leveraging advanced data analytics and networked automation technologies.

Electrical Substation vs Digital Substation Infographic

industrydif.com

industrydif.com