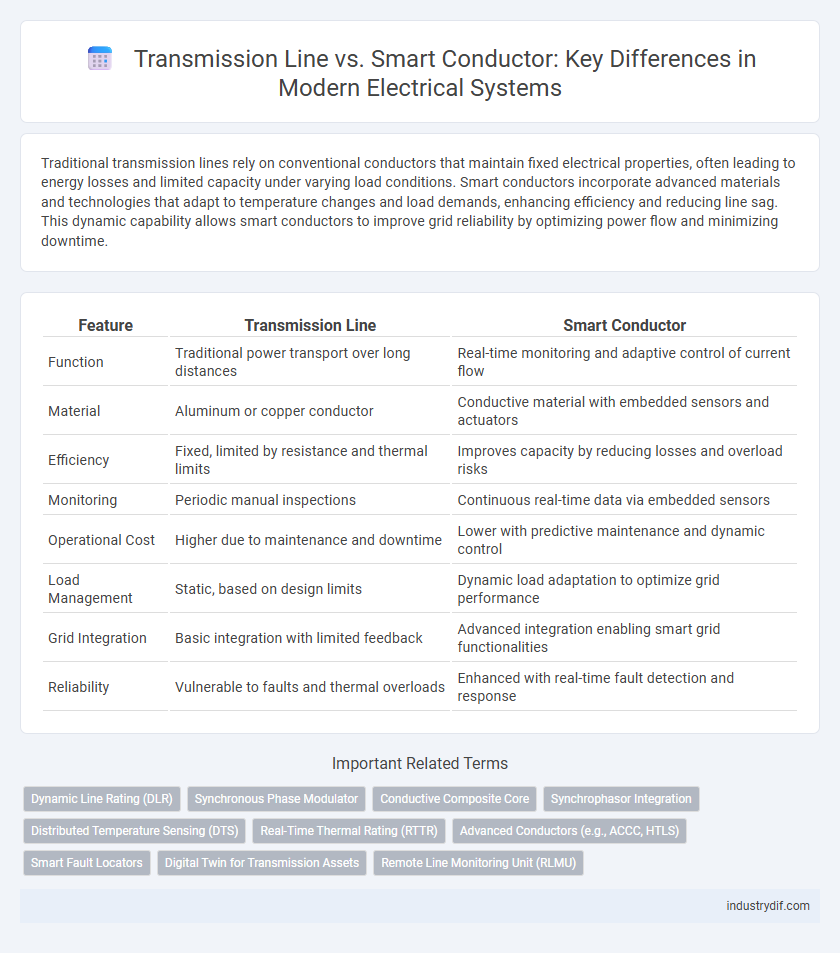

Traditional transmission lines rely on conventional conductors that maintain fixed electrical properties, often leading to energy losses and limited capacity under varying load conditions. Smart conductors incorporate advanced materials and technologies that adapt to temperature changes and load demands, enhancing efficiency and reducing line sag. This dynamic capability allows smart conductors to improve grid reliability by optimizing power flow and minimizing downtime.

Table of Comparison

| Feature | Transmission Line | Smart Conductor |

|---|---|---|

| Function | Traditional power transport over long distances | Real-time monitoring and adaptive control of current flow |

| Material | Aluminum or copper conductor | Conductive material with embedded sensors and actuators |

| Efficiency | Fixed, limited by resistance and thermal limits | Improves capacity by reducing losses and overload risks |

| Monitoring | Periodic manual inspections | Continuous real-time data via embedded sensors |

| Operational Cost | Higher due to maintenance and downtime | Lower with predictive maintenance and dynamic control |

| Load Management | Static, based on design limits | Dynamic load adaptation to optimize grid performance |

| Grid Integration | Basic integration with limited feedback | Advanced integration enabling smart grid functionalities |

| Reliability | Vulnerable to faults and thermal overloads | Enhanced with real-time fault detection and response |

Introduction to Transmission Lines and Smart Conductors

Transmission lines are essential components of the electrical power grid, designed to carry high-voltage electricity over long distances with minimal loss. Smart conductors integrate advanced materials and sensors to enhance transmission efficiency, reduce line losses, and provide real-time monitoring of line conditions. These innovative conductors optimize power delivery by adapting to environmental factors and load demands, representing a significant advancement over traditional transmission lines.

Key Differences Between Traditional Transmission Lines and Smart Conductors

Traditional transmission lines primarily rely on fixed copper or aluminum conductors for electricity transfer, which limits their ability to adjust to dynamic load conditions. Smart conductors incorporate advanced materials and embedded sensors, enabling real-time monitoring of temperature, current, and mechanical stress to optimize energy flow and enhance grid reliability. These innovations reduce energy losses and improve fault detection compared to conventional transmission infrastructure.

Technological Advancements in Smart Conductors

Smart conductors incorporate advanced materials like carbon nanotubes and superconductors, vastly improving conductivity and reducing energy losses compared to traditional transmission lines. These technological advancements enable real-time monitoring and adaptive load management, enhancing grid reliability and efficiency. Integration of sensors and IoT within smart conductors allows proactive maintenance, minimizing outages and extending the lifespan of the transmission infrastructure.

Efficiency and Performance Comparison

Smart conductors enhance transmission line efficiency by reducing line sag and losses under high temperatures, enabling greater current capacity without infrastructure upgrades. Their advanced materials allow improved conductivity and thermal management compared to traditional aluminum or copper lines, boosting overall performance. Adoption of smart conductors results in minimized energy dissipation and increased grid reliability, supporting efficient power delivery over long distances.

Impact on Grid Reliability and Stability

Transmission lines are the backbone of power grids, carrying high-voltage electricity over long distances but often face challenges such as line sag, thermal limits, and susceptibility to environmental conditions that can affect grid reliability and stability. Smart conductors incorporate advanced materials and sensors that enable real-time monitoring of temperature, tension, and electrical loads, allowing for dynamic response to changing grid conditions and reducing the risk of outages. Deploying smart conductor technology enhances grid resilience by optimizing line capacity, minimizing failures, and supporting stable power delivery in increasingly complex energy networks.

Cost Analysis: Installation and Maintenance

Transmission lines typically involve higher installation and maintenance costs due to extensive infrastructure requirements and frequent manual inspections. Smart conductors reduce overall expenses by incorporating sensors and automated monitoring systems, enabling predictive maintenance that minimizes downtime and repair costs. Investment in smart conductor technology results in long-term savings through improved efficiency and reduced operational disruptions.

Integration with Smart Grid Systems

Smart conductors enhance integration with smart grid systems by enabling real-time monitoring and adaptive load management, reducing losses and improving reliability compared to traditional transmission lines. Their advanced sensor technology facilitates precise fault detection and dynamic voltage control, optimizing grid performance and supporting renewable energy integration. This intelligent communication capability allows seamless coordination with grid operators, promoting efficient energy distribution and resilience in modern power networks.

Environmental and Safety Considerations

Smart conductors reduce energy losses and minimize environmental impact by maintaining optimal temperature control, which decreases the risk of overheating and wildfires compared to traditional transmission lines. Their advanced monitoring systems enhance safety by detecting faults early, preventing failures and reducing outage-related hazards for communities. Incorporating smart conductor technology supports sustainable energy infrastructure with lower ecological footprints and improved operational reliability.

Future Trends in Power Transmission Technology

Smart conductors represent a significant advancement over traditional transmission lines by integrating real-time monitoring, enhanced thermal capacity, and better efficiency to meet growing electricity demand. Future trends in power transmission technology emphasize the adoption of smart conductors to reduce energy losses, improve grid reliability, and enable dynamic load management in response to renewable energy fluctuations. These innovations facilitate the development of smarter grids, supporting the transition to sustainable and resilient energy systems worldwide.

Choosing Between Transmission Lines and Smart Conductors

Choosing between traditional transmission lines and smart conductors depends on factors such as grid efficiency, cost, and real-time monitoring capabilities. Smart conductors enhance grid performance by reducing line losses through dynamic capacity adjustments and integrated sensing technologies. Transmission lines remain a reliable infrastructure choice, but smart conductors offer improved operational flexibility and potential long-term savings.

Related Important Terms

Dynamic Line Rating (DLR)

Dynamic Line Rating (DLR) enhances the capacity of traditional transmission lines by continuously monitoring environmental conditions and conductor temperature to optimize current flow, significantly improving grid reliability and efficiency. Smart conductors equipped with real-time sensors enable precise DLR implementation, reducing the risk of overheating and allowing utilities to maximize existing infrastructure without costly upgrades.

Synchronous Phase Modulator

Transmission lines traditionally carry electricity over long distances but face issues like line sag and capacity limitations, whereas smart conductors equipped with synchronous phase modulators optimize power flow by dynamically adjusting phase angles, enhancing grid stability and efficiency. The synchronous phase modulator technology enables real-time control of current and voltage, reducing losses and increasing transmission capacity without the need for significant infrastructure upgrades.

Conductive Composite Core

Transmission lines using traditional steel cores provide high tensile strength but face limitations in conductivity and weight, whereas smart conductors with conductive composite cores combine advanced carbon fiber composites and conductive materials to significantly enhance electrical performance, reduce sag, and increase durability under thermal and mechanical stress. The conductive composite core's lightweight, high-strength properties improve grid efficiency and resilience, enabling higher power transfer capacity and lower energy losses compared to conventional aluminum conductor steel-reinforced (ACSR) lines.

Synchrophasor Integration

Transmission lines equipped with synchrophasor integration enable real-time monitoring of electrical parameters, enhancing grid stability and fault detection. Smart conductors embedded with synchrophasors provide granular data on voltage, current, and phase angles, optimizing load management and reducing transmission losses.

Distributed Temperature Sensing (DTS)

Distributed Temperature Sensing (DTS) enhances smart conductor technology by providing real-time temperature monitoring along transmission lines, enabling early detection of hotspots and preventing potential failures. This advanced sensing capability improves grid reliability and efficiency compared to traditional transmission lines without DTS integration.

Real-Time Thermal Rating (RTTR)

Real-Time Thermal Rating (RTTR) enhances transmission line capacity by continuously monitoring conductor temperature, weather, and electrical load parameters to optimize current carrying limits. Smart conductors equipped with RTTR sensors provide dynamic, accurate thermal data, reducing line sag and preventing overheating compared to traditional static rating methods.

Advanced Conductors (e.g., ACCC, HTLS)

Advanced conductors such as Aluminum Conductor Composite Core (ACCC) and High-Temperature Low-Sag (HTLS) conductors enhance transmission line capacity by reducing sag and allowing higher current loads without extensive infrastructure upgrades. These smart conductors improve grid reliability and efficiency by minimizing line losses and enabling real-time monitoring through integrated sensors.

Smart Fault Locators

Smart fault locators integrated with smart conductors enable precise real-time detection and isolation of faults in transmission lines, significantly reducing outage durations and maintenance costs. Advanced sensors and communication technologies in smart conductors enhance grid resilience by automatically pinpointing fault locations and facilitating rapid response.

Digital Twin for Transmission Assets

Digital Twin technology enhances the management of transmission lines by creating real-time virtual models that simulate physical behaviors, enabling predictive maintenance and reducing outages. Smart conductors equipped with sensors integrate seamlessly with Digital Twins, providing continuous data on temperature, tension, and environmental conditions to optimize asset performance and grid reliability.

Remote Line Monitoring Unit (RLMU)

A Remote Line Monitoring Unit (RLMU) integrated with smart conductors enables real-time data collection on current, temperature, and sag, enhancing transmission line reliability and reducing downtime. Unlike traditional transmission lines, RLMU-equipped smart conductors support predictive maintenance and dynamic load management through continuous remote monitoring and advanced analytics.

Transmission Line vs Smart Conductor Infographic

industrydif.com

industrydif.com