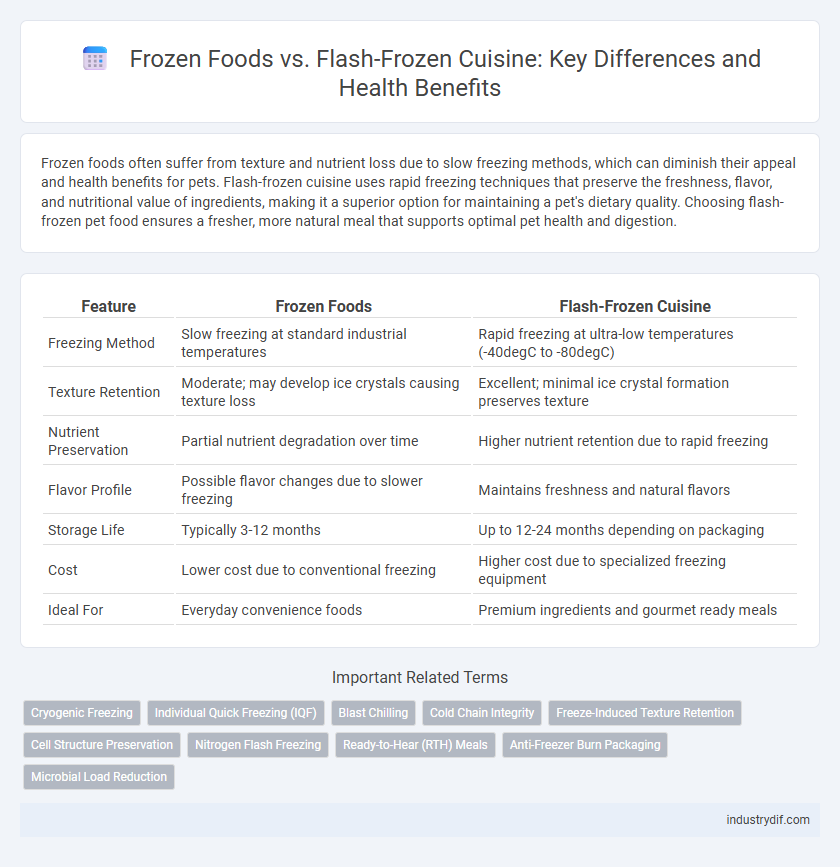

Frozen foods often suffer from texture and nutrient loss due to slow freezing methods, which can diminish their appeal and health benefits for pets. Flash-frozen cuisine uses rapid freezing techniques that preserve the freshness, flavor, and nutritional value of ingredients, making it a superior option for maintaining a pet's dietary quality. Choosing flash-frozen pet food ensures a fresher, more natural meal that supports optimal pet health and digestion.

Table of Comparison

| Feature | Frozen Foods | Flash-Frozen Cuisine |

|---|---|---|

| Freezing Method | Slow freezing at standard industrial temperatures | Rapid freezing at ultra-low temperatures (-40degC to -80degC) |

| Texture Retention | Moderate; may develop ice crystals causing texture loss | Excellent; minimal ice crystal formation preserves texture |

| Nutrient Preservation | Partial nutrient degradation over time | Higher nutrient retention due to rapid freezing |

| Flavor Profile | Possible flavor changes due to slower freezing | Maintains freshness and natural flavors |

| Storage Life | Typically 3-12 months | Up to 12-24 months depending on packaging |

| Cost | Lower cost due to conventional freezing | Higher cost due to specialized freezing equipment |

| Ideal For | Everyday convenience foods | Premium ingredients and gourmet ready meals |

Introduction to Frozen Foods and Flash-Frozen Cuisine

Frozen foods maintain nutritional value and flavor through slow freezing methods that can cause larger ice crystals and potential texture changes. Flash-frozen cuisine employs ultra-rapid freezing at extremely low temperatures, preserving cellular structure and freshness more effectively than conventional freezing. This technology ensures higher-quality taste and texture, making flash-frozen options popular for gourmet and ready-to-eat meals.

The Science Behind Freezing Techniques

Flash-frozen cuisine utilizes rapid freezing methods that create smaller ice crystals, preserving cell structure and nutritional content more effectively than traditional frozen foods, which often form larger ice crystals causing texture degradation. This advanced freezing technique maintains the food's original flavor, color, and nutrient density by minimizing enzymatic and microbial activity during the freezing process. Scientific studies highlight that flash freezing significantly reduces thaw drip loss, enhancing the sensory and quality attributes of fruits, vegetables, and seafood.

Key Differences: Traditional Freezing vs Flash-Freezing

Traditional freezing slowly lowers the temperature of food, causing large ice crystals to form that can damage cell structures and affect texture and flavor. Flash-freezing rapidly freezes food at extremely low temperatures, resulting in smaller ice crystals that better preserve the food's original quality, nutrients, and taste. The quicker process of flash-freezing reduces moisture loss and maintains the integrity of fresh ingredients compared to conventional methods.

Nutritional Retention: Which Method Wins?

Flash-frozen cuisine retains more nutrients than traditional frozen foods due to rapid freezing, which minimizes ice crystal formation and preserves cell integrity. Traditional freezing tends to cause larger ice crystals that damage food structure and lead to nutrient loss, particularly vitamins C and B complex. Studies show flash freezing can maintain up to 90-95% of original nutrients, whereas conventional freezing retains around 70-80%.

Flavor and Texture: Impact of Freezing Methods

Flash-frozen cuisine preserves cellular structure by rapidly lowering temperatures, resulting in superior flavor and texture retention compared to traditional frozen foods. Slow freezing causes ice crystals to grow larger, damaging cell walls and leading to mushier textures and flavor loss. Consumers seeking freshness and quality often prefer flash-frozen products for their closer resemblance to fresh ingredients.

Shelf Life and Storage Considerations

Frozen foods typically have a longer shelf life ranging from 3 to 12 months due to slower freezing processes that can cause larger ice crystals, potentially affecting texture. Flash-frozen cuisine uses ultra-rapid freezing technology that preserves cellular structure, extending shelf life up to 18 months while maintaining freshness and nutritional quality. Proper storage at consistent temperatures below -18degC is essential for both methods to prevent freezer burn and microbial growth, ensuring optimal flavor and safety.

Common Industry Applications and Products

Frozen foods dominate retail and foodservice sectors, including packaged vegetables, fruits, ready meals, and ice creams designed for long shelf life and convenience. Flash-frozen cuisine, rapidly frozen at ultra-low temperatures, preserves cellular structure and flavor, making it ideal for premium seafood, gourmet dishes, and fresh produce used in high-end restaurants and meal kit delivery services. Both methods serve the frozen food supply chain but cater to different market segments based on quality, texture retention, and preparation needs.

Consumer Perception and Market Trends

Flash-frozen cuisine retains superior nutritional value and texture compared to traditional frozen foods, influencing a growing consumer preference for fresher-tasting options. Market trends show increased demand for flash-frozen products, driven by health-conscious shoppers seeking convenience without sacrificing quality. Brands leveraging advanced flash-freezing technology report higher consumer satisfaction and premium pricing opportunities in the frozen food sector.

Sustainability and Energy Efficiency in Freezing Techniques

Flash-frozen cuisine utilizes rapid freezing methods that preserve nutrient content and texture more effectively than traditional frozen foods, reducing food waste by extending shelf life without compromising quality. This technique consumes less energy due to shorter freezing durations and advanced technology, making it a more sustainable option in food preservation. Compared to conventional freezing, flash freezing supports eco-friendly practices by minimizing resource use and lowering carbon emissions throughout the supply chain.

Future Innovations in Frozen Food Technology

Advancements in frozen food technology increasingly focus on flash-freezing methods that preserve texture, flavor, and nutritional value far better than traditional freezing techniques. Innovations such as cryogenic freezing and high-pressure processing enable rapid temperature reduction, minimizing ice crystal formation and maintaining the integrity of ingredients in frozen meals. Emerging trends also incorporate smart packaging and AI-driven quality control, ensuring optimal freshness and extending shelf life in future frozen food products.

Related Important Terms

Cryogenic Freezing

Cryogenic freezing uses liquid nitrogen at temperatures as low as -196degC to rapidly freeze food, preserving cellular structure, texture, and nutritional value far better than conventional frozen foods. This ultra-fast freezing method minimizes ice crystal formation, resulting in superior taste and quality in flash-frozen cuisine compared to traditional freezing techniques.

Individual Quick Freezing (IQF)

Individual Quick Freezing (IQF) preserves the texture, flavor, and nutritional value of frozen foods by rapidly freezing each piece separately, preventing clumping and maintaining product integrity. Flash-frozen cuisine utilizing IQF technology ensures superior quality and convenience compared to traditional frozen foods, making it ideal for retaining freshness and extending shelf life.

Blast Chilling

Blast chilling technology rapidly lowers the temperature of cooked foods to preserve flavor, texture, and nutritional value better than traditional freezing methods used in frozen foods. This flash-freezing process minimizes ice crystal formation, ensuring higher quality and extended shelf life in ready-to-cook meals.

Cold Chain Integrity

Maintaining cold chain integrity is crucial for frozen foods to preserve their nutritional quality and safety by preventing temperature fluctuations during storage and transport. Flash-frozen cuisine, rapidly frozen at extremely low temperatures, ensures cellular structure and flavor retention by minimizing ice crystal formation, thereby enhancing freshness compared to traditional frozen foods.

Freeze-Induced Texture Retention

Freeze-induced texture retention in flash-frozen cuisine outperforms traditional frozen foods by rapidly preserving cellular integrity and minimizing ice crystal formation, which prevents moisture loss and maintains the food's original mouthfeel. This advanced freezing technique ensures superior freshness, flavor retention, and texture quality compared to conventional slow freezing methods commonly used in standard frozen products.

Cell Structure Preservation

Flash-frozen cuisine preserves cell structure more effectively than traditional frozen foods by rapidly lowering the temperature, which minimizes ice crystal formation and prevents cell wall rupture. This technique maintains the texture, flavor, and nutritional value of ingredients, offering a superior quality compared to conventional frozen products.

Nitrogen Flash Freezing

Nitrogen flash freezing preserves the texture, flavor, and nutritional value of foods by rapidly lowering the temperature with liquid nitrogen, preventing large ice crystals from forming. This method outperforms traditional frozen foods by maintaining higher quality and freshness, making it ideal for premium frozen cuisine.

Ready-to-Hear (RTH) Meals

Ready-to-Eat (RTE) meals in frozen foods offer convenience but may compromise texture and flavor due to slower freezing processes, whereas flash-frozen cuisine preserves nutritional quality, taste, and appearance by rapidly freezing meals at extremely low temperatures. Flash-freezing locks in freshness and reduces ice crystal formation, making it superior for maintaining the integrity of ready-to-heat meals in comparison to traditional frozen food techniques.

Anti-Freezer Burn Packaging

Flash-frozen cuisine utilizes advanced anti-freezer burn packaging that significantly reduces ice crystal formation, preserving texture, flavor, and nutritional quality better than traditional frozen foods. This innovative packaging incorporates moisture-resistant barriers and vacuum-sealing technology to prevent freezer burn, extending shelf life and maintaining optimal food freshness.

Microbial Load Reduction

Flash-frozen cuisine significantly reduces microbial load by rapidly lowering food temperature, which halts bacterial growth more effectively than conventional freezing methods. This rapid freezing process preserves food safety and extends shelf life while maintaining nutritional quality compared to standard frozen foods.

Frozen foods vs Flash-frozen cuisine Infographic

industrydif.com

industrydif.com