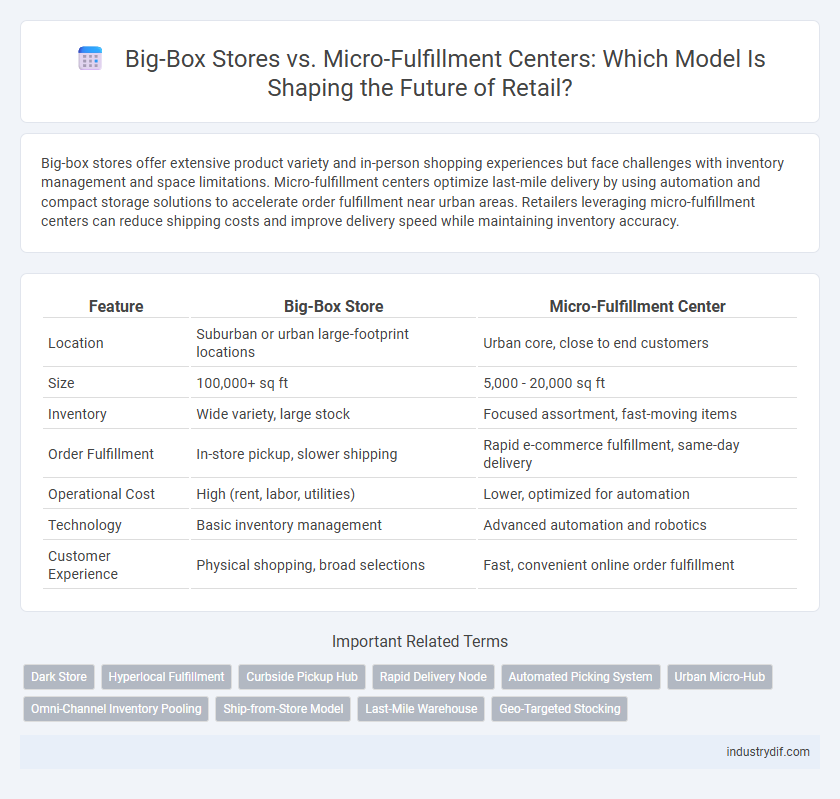

Big-box stores offer extensive product variety and in-person shopping experiences but face challenges with inventory management and space limitations. Micro-fulfillment centers optimize last-mile delivery by using automation and compact storage solutions to accelerate order fulfillment near urban areas. Retailers leveraging micro-fulfillment centers can reduce shipping costs and improve delivery speed while maintaining inventory accuracy.

Table of Comparison

| Feature | Big-Box Store | Micro-Fulfillment Center |

|---|---|---|

| Location | Suburban or urban large-footprint locations | Urban core, close to end customers |

| Size | 100,000+ sq ft | 5,000 - 20,000 sq ft |

| Inventory | Wide variety, large stock | Focused assortment, fast-moving items |

| Order Fulfillment | In-store pickup, slower shipping | Rapid e-commerce fulfillment, same-day delivery |

| Operational Cost | High (rent, labor, utilities) | Lower, optimized for automation |

| Technology | Basic inventory management | Advanced automation and robotics |

| Customer Experience | Physical shopping, broad selections | Fast, convenient online order fulfillment |

Big-Box Store Overview

Big-box stores are large-scale retail establishments typically exceeding 50,000 square feet, offering a wide variety of products under one roof, which drives high foot traffic and significant in-store sales volume. These stores rely on strategic location and extensive inventory to meet diverse consumer needs, supporting consumer shopping preferences for immediate product availability. The traditional big-box retail model faces challenges from e-commerce growth, prompting investments in omnichannel strategies and integration with micro-fulfillment centers to enhance last-mile delivery efficiency.

Micro-Fulfillment Center Explained

Micro-fulfillment centers (MFCs) are compact, automated warehouses located close to urban consumers, designed to expedite order fulfillment for e-commerce and omnichannel retail. Unlike large big-box stores that require extensive floor space and inventory, MFCs leverage advanced robotics and AI to maximize efficiency in a smaller footprint, reducing delivery times and last-mile costs. Retailers adopting micro-fulfillment centers benefit from faster stock turnover and enhanced customer satisfaction through rapid, accurate order processing.

Operational Scale Differences

Big-box stores typically operate on a large operational scale, offering extensive inventory across diverse product categories in expansive physical locations exceeding 100,000 square feet. Micro-fulfillment centers function on a much smaller footprint, often under 10,000 square feet, specializing in rapid order processing and localized distribution to enhance e-commerce fulfillment efficiency. The operational scale difference impacts inventory management, labor allocation, and supply chain logistics, with big-box stores prioritizing in-store shopping experiences and micro-fulfillment centers emphasizing speed and automation for last-mile delivery.

Inventory Management Strategies

Big-box stores leverage extensive shelf space to stock a broad variety of products, enabling bulk inventory storage and immediate customer access, which supports high-volume sales and reduces stockouts. Micro-fulfillment centers utilize automated systems and data analytics to optimize inventory turnover, prioritize fast-moving items, and enable rapid order fulfillment for e-commerce and omnichannel retail. Combining real-time inventory tracking with localized storage, micro-fulfillment centers minimize holding costs and enhance supply chain responsiveness compared to traditional large-format retail models.

Customer Experience Comparison

Big-box stores provide customers with a wide selection of products under one roof, enabling immediate, in-person shopping experiences with the ability to inspect items before purchase. Micro-fulfillment centers leverage automation and proximity to urban areas to expedite order processing and delivery times, enhancing convenience through faster home delivery or curbside pickup options. Customer satisfaction in micro-fulfillment models often stems from efficiency and speed, while big-box stores excel in offering tactile shopping and extensive product variety.

Location and Footprint Analysis

Big-box stores typically require expansive locations of 50,000 to 200,000 square feet, often situated in suburban areas with ample parking to accommodate high customer traffic and bulk inventory storage. Micro-fulfillment centers occupy significantly smaller footprints, around 10,000 to 20,000 square feet, and are strategically located within urban or densely populated environments to enable rapid order fulfillment and reduce last-mile delivery costs. The spatial efficiency and proximity of micro-fulfillment centers to consumers enhance speed and convenience, contrasting with big-box stores' emphasis on a comprehensive in-store shopping experience.

Technology Integration in Retail

Big-box stores leverage extensive physical space and traditional inventory systems but face challenges in rapid order fulfillment and real-time inventory tracking. Micro-fulfillment centers utilize advanced robotics, AI, and IoT technologies to streamline order processing, enhance delivery speed, and optimize stock management within compact urban locations. Integrating micro-fulfillment tech with existing retail systems enables seamless omnichannel retail experiences and boosts operational efficiency.

Supply Chain Efficiency

Big-box stores typically require extensive inventory storage on-site, leading to higher carrying costs and slower replenishment cycles, whereas micro-fulfillment centers use automated systems to accelerate order processing and reduce storage footprint near urban areas. Micro-fulfillment centers enhance supply chain efficiency by minimizing last-mile delivery times and optimizing inventory distribution based on real-time demand data. This approach enables retailers to meet growing e-commerce demands while lowering overall logistics expenses and improving customer satisfaction.

Cost Structures and Profit Margins

Big-box stores incur high fixed costs related to extensive real estate, inventory management, and in-store staffing, which can squeeze profit margins despite high sales volumes. Micro-fulfillment centers reduce overhead by automating inventory handling and utilizing smaller spaces closer to urban customers, leading to lower operational costs and improved margin efficiency. Optimizing cost structures through micro-fulfillment enables retailers to increase profitability by accelerating order fulfillment and reducing last-mile delivery expenses.

Future Trends in Retail Fulfillment

Big-box stores are evolving by integrating micro-fulfillment centers to enhance speed and efficiency in order fulfillment, addressing the increasing demand for rapid delivery in urban areas. Micro-fulfillment centers leverage automation and AI-driven inventory management, reducing last-mile delivery times and operational costs while supporting omnichannel retail strategies. Future trends indicate a hybrid model where traditional large-format stores coexist with strategically placed micro-fulfillment hubs to optimize both in-store experience and e-commerce fulfillment.

Related Important Terms

Dark Store

Dark stores in retail function as micro-fulfillment centers optimized for rapid order processing within urban areas, significantly reducing delivery times compared to traditional big-box stores that rely on larger physical footprints for in-person shopping. These dark stores leverage automation and proximity to consumers, enhancing inventory management efficiency and meeting growing e-commerce demand without the overhead of customer-facing operations.

Hyperlocal Fulfillment

Big-box stores offer expansive inventory and in-store shopping experiences, but micro-fulfillment centers excel in hyperlocal fulfillment by enabling rapid order processing and delivery within a few miles of urban customer clusters. Leveraging automation and compact storage, micro-fulfillment centers reduce last-mile delivery times and enhance inventory turnover, making them vital for retailers aiming to capture immediate local demand.

Curbside Pickup Hub

Big-box stores leverage extensive inventory and spacious layouts to facilitate curbside pickup hubs that handle high order volumes efficiently, enhancing customer convenience and reducing in-store congestion. Micro-fulfillment centers optimize last-mile delivery by utilizing automated storage and retrieval systems near urban areas, enabling faster order processing and improved accuracy for curbside pickup services.

Rapid Delivery Node

Big-box stores serve as traditional retail hubs with extensive inventory but slower delivery speeds, whereas micro-fulfillment centers act as rapid delivery nodes strategically located near urban areas to enable same-day or two-hour delivery. These centers leverage automation and proximity to customer clusters to optimize last-mile logistics, significantly reducing delivery times and operational costs compared to large-format retail stores.

Automated Picking System

Big-box stores typically rely on manual or semi-automated picking systems that manage high product variety but face challenges in speed and accuracy, whereas micro-fulfillment centers utilize advanced automated picking systems designed to maximize efficiency and reduce labor costs in compact spaces. Automated picking systems in micro-fulfillment centers leverage robotics, AI, and real-time inventory management to rapidly process online orders, significantly enhancing order accuracy and fulfillment speed compared to traditional big-box store operations.

Urban Micro-Hub

Urban micro-fulfillment centers optimize retail supply chains by enabling faster last-mile delivery and reducing transportation costs compared to traditional big-box stores, which require larger physical footprints and inventory management. These compact facilities utilize automation and data analytics to efficiently serve dense urban populations, enhancing customer convenience and reducing environmental impact.

Omni-Channel Inventory Pooling

Big-box stores traditionally rely on large, centralized inventory, while micro-fulfillment centers enhance omni-channel inventory pooling by enabling rapid, localized order fulfillment and reducing last-mile delivery costs. Leveraging advanced automation and real-time inventory synchronization, micro-fulfillment centers improve stock accuracy and customer experience across physical and digital retail channels.

Ship-from-Store Model

Big-box stores leverage vast inventory and physical space to fulfill orders directly from their retail locations, enhancing speed and reducing last-mile delivery costs through the ship-from-store model. Micro-fulfillment centers optimize urban retail logistics by utilizing automation and proximity to customers, enabling faster order processing and greater inventory accuracy within smaller footprints.

Last-Mile Warehouse

Big-box stores rely on expansive physical locations to stock diverse inventory, enhancing direct customer access but facing challenges in rapid fulfillment and last-mile delivery efficiency. Micro-fulfillment centers, strategically positioned within urban areas, optimize last-mile logistics by enabling faster order processing and reducing delivery times through automated storage and retrieval systems.

Geo-Targeted Stocking

Big-box stores maintain large inventories centralized in extensive retail spaces, limiting agility in stock distribution and reducing responsiveness to local demand variations. Micro-fulfillment centers utilize geo-targeted stocking strategies by deploying smaller, automated warehouses closer to urban hubs, enhancing inventory precision, reducing delivery times, and optimizing local consumer preferences.

Big-box store vs Micro-fulfillment center Infographic

industrydif.com

industrydif.com