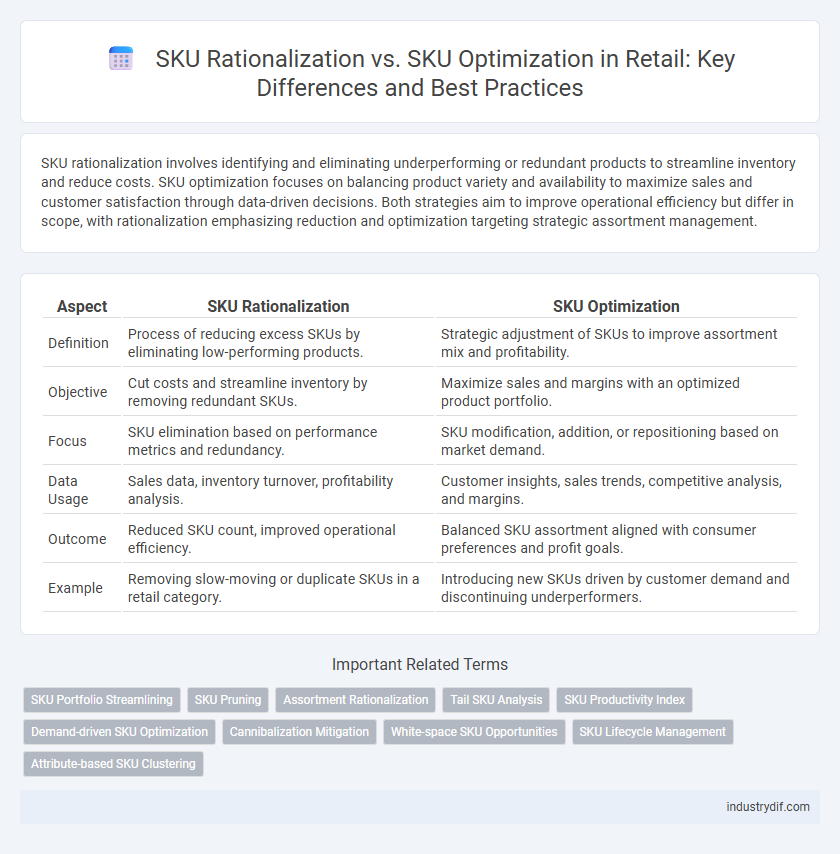

SKU rationalization involves identifying and eliminating underperforming or redundant products to streamline inventory and reduce costs. SKU optimization focuses on balancing product variety and availability to maximize sales and customer satisfaction through data-driven decisions. Both strategies aim to improve operational efficiency but differ in scope, with rationalization emphasizing reduction and optimization targeting strategic assortment management.

Table of Comparison

| Aspect | SKU Rationalization | SKU Optimization |

|---|---|---|

| Definition | Process of reducing excess SKUs by eliminating low-performing products. | Strategic adjustment of SKUs to improve assortment mix and profitability. |

| Objective | Cut costs and streamline inventory by removing redundant SKUs. | Maximize sales and margins with an optimized product portfolio. |

| Focus | SKU elimination based on performance metrics and redundancy. | SKU modification, addition, or repositioning based on market demand. |

| Data Usage | Sales data, inventory turnover, profitability analysis. | Customer insights, sales trends, competitive analysis, and margins. |

| Outcome | Reduced SKU count, improved operational efficiency. | Balanced SKU assortment aligned with consumer preferences and profit goals. |

| Example | Removing slow-moving or duplicate SKUs in a retail category. | Introducing new SKUs driven by customer demand and discontinuing underperformers. |

Understanding SKU Rationalization in Retail

SKU rationalization in retail involves analyzing and reducing the number of stock-keeping units (SKUs) to eliminate underperforming products, streamline inventory, and improve overall profitability. This process focuses on identifying low-selling or redundant SKUs that increase carrying costs and complicate inventory management. Understanding SKU rationalization enables retailers to enhance shelf space productivity, optimize supply chain efficiency, and better align product assortment with customer demand.

What is SKU Optimization?

SKU optimization involves analyzing product performance data, customer demand, and profitability to strategically adjust the assortment of stock-keeping units (SKUs) in retail. This process aims to maximize sales, reduce inventory costs, and improve shelf space efficiency by retaining high-performing SKUs and eliminating underperforming ones. Effective SKU optimization enhances inventory turnover rates and drives higher gross margins for retailers.

Key Differences Between SKU Rationalization and SKU Optimization

SKU Rationalization focuses on identifying and eliminating underperforming or redundant stock-keeping units to reduce inventory costs and improve operational efficiency. SKU Optimization involves adjusting the product mix and inventory levels based on demand forecasting, sales data, and market trends to maximize revenue and customer satisfaction. Key differences lie in SKU Rationalization's cost-cutting approach versus SKU Optimization's emphasis on balancing inventory availability with sales performance.

Benefits of Effective SKU Rationalization

Effective SKU rationalization in retail reduces inventory carrying costs by eliminating underperforming products, enhancing supply chain efficiency and improving shelf space utilization to boost sales per square foot. Streamlined SKU assortments lead to better demand forecasting, reduced stockouts, and decreased markdowns, driving higher profitability and customer satisfaction. Focusing on core, high-turn SKUs also supports targeted marketing efforts and inventory replenishment accuracy, maximizing overall operational performance.

Advantages of SKU Optimization for Retailers

SKU optimization enhances inventory efficiency by focusing on high-performing products and eliminating underperforming SKUs, leading to improved sales and reduced holding costs. It enables retailers to better align their product assortment with customer demand, increasing shelf space productivity and boosting profitability. Optimized SKUs streamline supply chain operations and enhance decision-making through data-driven insights, supporting agile responses to market trends.

Challenges in Implementing SKU Rationalization

Implementing SKU rationalization in retail faces challenges such as data complexity, inaccurate demand forecasting, and resistance from stakeholders fearing reduced product variety. Managers must analyze sales, inventory turnover, and profitability metrics to identify underperforming SKUs without alienating loyal customers. Overcoming these obstacles requires robust analytics systems and cross-functional collaboration to ensure efficient SKU portfolios and improved supply chain efficiency.

Best Practices for SKU Optimization

Effective SKU optimization focuses on analyzing sales data, customer demand, and inventory turnover to identify the highest-performing products while eliminating underperforming SKUs. Utilizing advanced analytics and demand forecasting models enables retailers to maintain an optimal SKU mix that maximizes shelf space efficiency and profitability. Continuous monitoring and cross-functional collaboration between merchandising, supply chain, and marketing teams ensure agile adjustments to SKU assortments aligned with market trends and consumer preferences.

How Data Drives SKU Decisions in Retail

SKU rationalization and SKU optimization both rely heavily on data analytics to enhance retail performance by evaluating product profitability, turnover rates, and customer preferences. Advanced data tools enable retailers to identify underperforming SKUs for elimination while optimizing inventory levels of high-demand items to improve shelf space efficiency and reduce carrying costs. Leveraging sales data, market trends, and consumer behavior insights ensures that SKU decisions drive higher revenue and operational agility in retail management.

Impact on Inventory Management and Supply Chain

SKU rationalization reduces inventory complexity by eliminating underperforming products, leading to lower holding costs and streamlined supply chain operations. SKU optimization enhances inventory management by analyzing demand patterns to balance stock levels, ensuring product availability while minimizing excess inventory. Together, these strategies improve forecast accuracy, reduce lead times, and increase overall supply chain efficiency in retail environments.

Case Studies: Successful SKU Strategies in Retail

Case studies of successful SKU strategies in retail reveal that SKU rationalization focuses on reducing product complexity by eliminating underperforming items, leading to improved inventory turnover and reduced carrying costs. In contrast, SKU optimization leverages data analytics to balance product variety with customer demand, maximizing sales and profitability through targeted assortment planning. Retailers like Walmart and Target demonstrate how combining these approaches enhances operational efficiency and drives revenue growth.

Related Important Terms

SKU Portfolio Streamlining

SKU portfolio streamlining involves SKU rationalization, which removes underperforming or redundant products to reduce complexity and costs, while SKU optimization focuses on balancing assortment breadth and depth to maximize sales and enhance inventory turnover. Effective SKU portfolio management drives profitability by aligning product offerings with consumer demand and operational efficiency in retail environments.

SKU Pruning

SKU pruning involves the strategic removal of underperforming or redundant SKUs to streamline inventory and improve sales efficiency, while SKU optimization focuses on balancing assortment breadth with customer demand to maximize profitability. Effective SKU pruning reduces carrying costs, minimizes stock obsolescence, and enhances product salability by concentrating resources on high-performing items.

Assortment Rationalization

SKU Rationalization focuses on reducing the number of stock keeping units (SKUs) by eliminating underperforming or redundant products to streamline inventory and reduce costs. SKU Optimization, particularly through Assortment Rationalization, involves strategically selecting and balancing SKUs to maximize sales, improve customer satisfaction, and enhance overall retail profitability.

Tail SKU Analysis

SKU rationalization focuses on reducing excess inventory by eliminating underperforming SKUs, streamlining the product assortment to improve operational efficiency and reduce costs. SKU optimization, particularly through tail SKU analysis, identifies opportunities to enhance sales and profitability by strategically managing low-volume, low-demand products without necessarily removing them from the portfolio.

SKU Productivity Index

SKU Rationalization involves eliminating underperforming SKUs based on low sales and inventory turnover, while SKU Optimization focuses on balancing assortment breadth to maximize overall SKU Productivity Index, which measures sales per SKU relative to shelf space and cost. Improving the SKU Productivity Index drives higher revenue and profitability by ensuring each SKU contributes efficiently to sales without excess inventory or markdown risk.

Demand-driven SKU Optimization

SKU rationalization involves reducing the number of stock keeping units by eliminating underperforming products, while demand-driven SKU optimization leverages real-time sales data and customer insights to adjust inventory dynamically, ensuring optimal product availability and maximizing profitability. Advanced analytics and AI-driven forecasting enable retailers to precisely align SKU assortment with evolving consumer demand, enhancing supply chain efficiency and minimizing stockouts or excess inventory.

Cannibalization Mitigation

SKU rationalization reduces the total number of stock keeping units by eliminating underperforming or redundant products, directly addressing cannibalization through product line simplification. SKU optimization focuses on enhancing the performance of retained products by fine-tuning assortment, pricing, and placement strategies, thereby mitigating cannibalization effects while maximizing overall category revenue.

White-space SKU Opportunities

SKU rationalization systematically eliminates underperforming SKUs to reduce complexity and increase profitability, whereas SKU optimization identifies white-space SKU opportunities by analyzing gaps in the product assortment to meet unmet customer demand and drive incremental sales. Leveraging advanced analytics and customer insights, retailers can uncover these white-space SKU opportunities to strategically expand their portfolio while maintaining operational efficiency.

SKU Lifecycle Management

SKU rationalization focuses on reducing the number of SKUs by eliminating underperforming products to streamline inventory and improve profitability, whereas SKU optimization involves strategically managing the entire SKU lifecycle-- from introduction to phase-out-- to maximize sales and customer satisfaction. Effective SKU lifecycle management integrates data-driven analysis, forecasting demand, and aligning product assortments with market trends to enhance retail efficiency and responsiveness.

Attribute-based SKU Clustering

SKU rationalization focuses on eliminating underperforming products to streamline inventory, while SKU optimization enhances assortment profitability by analyzing attribute-based SKU clustering, grouping products based on shared characteristics like size, color, or price. Attribute-based SKU clustering enables retailers to identify redundant SKUs and optimize stock levels, improving customer choice and operational efficiency.

SKU Rationalization vs SKU Optimization Infographic

industrydif.com

industrydif.com