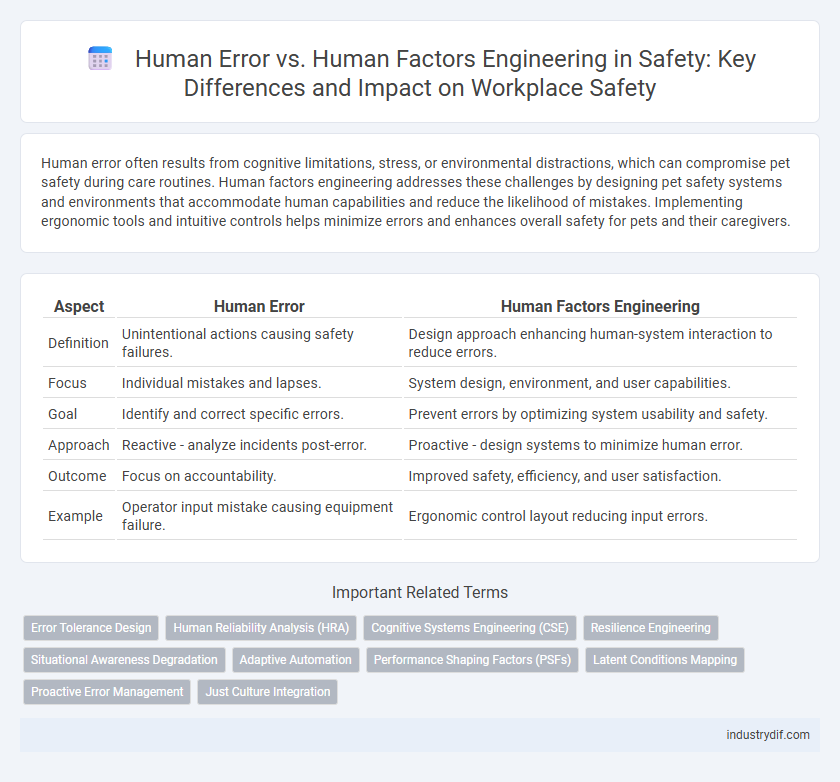

Human error often results from cognitive limitations, stress, or environmental distractions, which can compromise pet safety during care routines. Human factors engineering addresses these challenges by designing pet safety systems and environments that accommodate human capabilities and reduce the likelihood of mistakes. Implementing ergonomic tools and intuitive controls helps minimize errors and enhances overall safety for pets and their caregivers.

Table of Comparison

| Aspect | Human Error | Human Factors Engineering |

|---|---|---|

| Definition | Unintentional actions causing safety failures. | Design approach enhancing human-system interaction to reduce errors. |

| Focus | Individual mistakes and lapses. | System design, environment, and user capabilities. |

| Goal | Identify and correct specific errors. | Prevent errors by optimizing system usability and safety. |

| Approach | Reactive - analyze incidents post-error. | Proactive - design systems to minimize human error. |

| Outcome | Focus on accountability. | Improved safety, efficiency, and user satisfaction. |

| Example | Operator input mistake causing equipment failure. | Ergonomic control layout reducing input errors. |

Defining Human Error in Industrial Safety

Human error in industrial safety refers to unintentional actions or decisions that deviate from established procedures, leading to accidents or near misses. It is often influenced by complex interactions between operator behavior, environmental conditions, and system design. Human Factors Engineering aims to minimize these errors by optimizing workplace ergonomics, enhancing user interface design, and implementing fail-safes that account for human limitations and cognitive biases.

Introduction to Human Factors Engineering

Human Factors Engineering (HFE) systematically integrates principles of psychology, ergonomics, and cognitive science to design systems that accommodate human capabilities and limitations, reducing error incidence in safety-critical environments. Unlike traditional views attributing accidents solely to human error, HFE emphasizes optimizing system design to support human performance and resilience. This approach enhances safety by addressing the root causes of errors through improved interfaces, workflows, and environmental conditions tailored to human behavior.

Key Differences Between Human Error and Human Factors

Human error refers to actions or decisions that deviate from intended performance, often causing accidents or failures, while human factors engineering focuses on designing systems and environments to accommodate human abilities and limitations. Key differences include that human error is typically seen as an outcome or symptom, whereas human factors engineering is a proactive discipline aimed at minimizing errors through ergonomic principles and user-centered design. Emphasizing human factors engineering improves safety by addressing the root causes of errors, such as cognitive overload, poor interface design, and inadequate training.

Root Causes of Human Error in Safety Incidents

Human error in safety incidents often stems from underlying system flaws rather than individual mistakes, with root causes linked to poorly designed work environments, inadequate training, and unclear procedures. Human Factors Engineering addresses these issues by optimizing system interfaces, improving task design, and enhancing communication protocols to reduce cognitive overload and prevent errors. Effective application of Human Factors Engineering principles minimizes risks by aligning safety management systems with human capabilities and limitations.

The Role of Human Factors Engineering in Accident Prevention

Human Factors Engineering plays a critical role in accident prevention by systematically designing systems that accommodate human limitations and enhance performance. It addresses not only human error but also the interactions between humans, machines, and environments to reduce risk and improve safety outcomes. Incorporating ergonomic design, cognitive workload management, and user-centered interfaces directly minimizes error potential and supports safer operational practices.

Traditional Approaches to Managing Human Error

Traditional approaches to managing human error often emphasize individual responsibility, training, and adherence to procedures to reduce mistakes. These methods typically involve error detection, correction, and punitive measures aimed at the human operator, rather than examining systemic issues. Human Factors Engineering shifts this focus by designing systems that accommodate human limitations and enhance overall safety performance through ergonomic and cognitive support.

Integrating Human Factors into Safety Management Systems

Integrating human factors engineering into safety management systems enhances error prevention by addressing the cognitive, physical, and organizational aspects influencing human performance. Human error is redefined as a symptom of deeper systemic issues rather than isolated faults, promoting design improvements that align with user capabilities and limitations. Emphasizing human factors supports resilience and adaptability in safety protocols, reducing incident rates and improving overall operational safety.

Case Studies: Human Error vs. Human Factors Solutions

Case studies in safety demonstrate that human error often stems from systemic design flaws rather than individual negligence, highlighting the importance of human factors engineering in creating safer work environments. For instance, investigations into industrial accidents reveal that redesigning tools, interfaces, or workflows significantly reduces error rates by accommodating human cognitive and physical capabilities. Implementing human factors solutions, such as standardized procedures and ergonomic adjustments, consistently leads to improved safety outcomes compared to focusing solely on blame or retraining employees.

Best Practices for Reducing Human Error through Engineering

Human Factors Engineering prioritizes designing systems that accommodate human limitations to reduce the incidence of human error. Implementing ergonomic controls, intuitive interfaces, and fail-safe mechanisms decreases cognitive load and prevents mistakes in high-risk environments. Best practices include continuous user testing and iterative design improvements to align technology with human capabilities, thereby enhancing overall safety.

Future Trends in Human Factors and Industrial Safety

Future trends in human factors engineering emphasize integrating artificial intelligence and wearable technology to predict and mitigate human error in industrial safety environments. Advanced data analytics and machine learning algorithms are being developed to monitor operator behavior and environmental conditions, enabling proactive risk management. Embracing ergonomic design principles alongside real-time feedback systems enhances worker performance and reduces accident rates across complex industrial operations.

Related Important Terms

Error Tolerance Design

Human Factors Engineering emphasizes designing systems with error tolerance to minimize the impact of human error, ensuring safety by anticipating and accommodating potential mistakes. Error tolerance design integrates redundancy, fail-safes, and intuitive interfaces to reduce the likelihood of accidents caused by human performance limitations.

Human Reliability Analysis (HRA)

Human Reliability Analysis (HRA) systematically quantifies the likelihood of human errors within complex systems, enabling the identification and mitigation of potential safety risks. Integrating HRA with Human Factors Engineering enhances the design of interfaces and processes by considering cognitive, physical, and organizational factors that influence operator performance.

Cognitive Systems Engineering (CSE)

Human Error often stems from system design flaws overlooking cognitive workload and decision-making complexity, whereas Human Factors Engineering, particularly Cognitive Systems Engineering (CSE), systematically integrates cognitive processes into safety-critical system design to enhance operator performance and reduce accidents. CSE focuses on optimizing interaction between humans and technology by analyzing mental models, situation awareness, and cognitive demands, thereby proactively mitigating risks associated with human error.

Resilience Engineering

Human error is often a symptom rather than the root cause of safety incidents, with Human Factors Engineering emphasizing the design of systems that accommodate human limitations and support optimal performance. Resilience Engineering further advances safety by focusing on the capacity of socio-technical systems to adapt, recover, and maintain operations under varying and unexpected conditions, thereby reducing the likelihood and impact of errors.

Situational Awareness Degradation

Human error in safety-critical environments often stems from situational awareness degradation, where individuals fail to perceive, comprehend, or project environmental elements accurately. Human Factors Engineering addresses this by designing systems that enhance cognitive processing, reduce complexity, and support timely decision-making to mitigate the risk of errors caused by impaired situational awareness.

Adaptive Automation

Adaptive automation enhances safety by dynamically adjusting system controls based on real-time human performance, reducing human error caused by cognitive overload and fatigue. Incorporating human factors engineering principles allows for designing interfaces that optimize operator situational awareness and decision-making, minimizing risks in complex operational environments.

Performance Shaping Factors (PSFs)

Performance Shaping Factors (PSFs) in human factors engineering critically influence human error by affecting cognition, decision-making, and physical capabilities during task execution. Identifying and optimizing PSFs such as workload, environment, ergonomics, and training reduces error probability and enhances system safety.

Latent Conditions Mapping

Latent conditions mapping in human factors engineering identifies hidden systemic vulnerabilities that contribute to human errors in safety-critical environments. By analyzing these underlying conditions, organizations can implement proactive design changes that minimize error likelihood and enhance overall safety performance.

Proactive Error Management

Human Factors Engineering integrates design principles and system improvements to proactively reduce human error by addressing cognitive, environmental, and organizational influences. Proactive error management emphasizes identifying potential failure points before incidents occur, enhancing safety through predictive analysis and system resilience rather than reactive blame on individuals.

Just Culture Integration

Human error analysis shifts to human factors engineering by emphasizing system design and environmental influences rather than individual blame, fostering a just culture that promotes accountability and learning. Integrating just culture principles ensures reporting of incidents without fear, enhancing safety through continuous organizational improvement and error prevention.

Human Error vs Human Factors Engineering Infographic

industrydif.com

industrydif.com