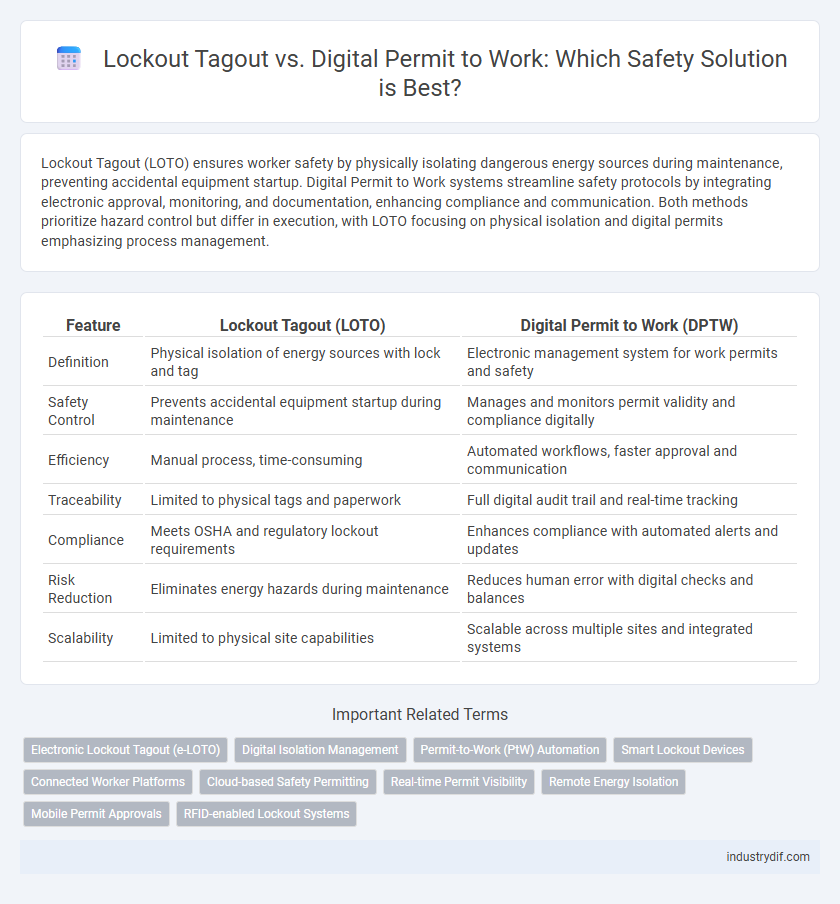

Lockout Tagout (LOTO) ensures worker safety by physically isolating dangerous energy sources during maintenance, preventing accidental equipment startup. Digital Permit to Work systems streamline safety protocols by integrating electronic approval, monitoring, and documentation, enhancing compliance and communication. Both methods prioritize hazard control but differ in execution, with LOTO focusing on physical isolation and digital permits emphasizing process management.

Table of Comparison

| Feature | Lockout Tagout (LOTO) | Digital Permit to Work (DPTW) |

|---|---|---|

| Definition | Physical isolation of energy sources with lock and tag | Electronic management system for work permits and safety |

| Safety Control | Prevents accidental equipment startup during maintenance | Manages and monitors permit validity and compliance digitally |

| Efficiency | Manual process, time-consuming | Automated workflows, faster approval and communication |

| Traceability | Limited to physical tags and paperwork | Full digital audit trail and real-time tracking |

| Compliance | Meets OSHA and regulatory lockout requirements | Enhances compliance with automated alerts and updates |

| Risk Reduction | Eliminates energy hazards during maintenance | Reduces human error with digital checks and balances |

| Scalability | Limited to physical site capabilities | Scalable across multiple sites and integrated systems |

Introduction to Lockout Tagout (LOTO) and Digital Permit to Work (PTW)

Lockout Tagout (LOTO) is a critical safety procedure that ensures machinery and equipment are properly shut off and isolated to prevent accidental startup during maintenance or repair. Digital Permit to Work (PTW) systems enhance traditional safety protocols by providing electronic authorization, real-time monitoring, and streamlined communication for hazardous work activities. Both methods aim to reduce workplace accidents by controlling energy sources and ensuring compliance with safety regulations.

Key Definitions: LOTO vs Digital PTW

Lockout Tagout (LOTO) is a safety procedure that involves physically isolating energy sources using locks and tags to prevent accidental machine startup during maintenance or repair. Digital Permit to Work (Digital PTW) systems use electronic platforms to manage and authorize work permits, enhancing risk assessment, communication, and compliance tracking in hazardous environments. Both LOTO and Digital PTW aim to ensure worker safety, but LOTO focuses on energy isolation, while Digital PTW facilitates comprehensive work control and documentation.

Regulatory Compliance and Industry Standards

Lockout Tagout (LOTO) procedures comply with OSHA standard 29 CFR 1910.147, ensuring control of hazardous energy during equipment maintenance. Digital Permit to Work (PTW) systems enhance regulatory compliance by integrating real-time safety checks and auditable records aligned with ISO 45001 occupational health and safety management standards. Both methods support industry mandates, but digital PTW offers scalable control and improved tracking for complex operational environments.

Advantages and Limitations of Traditional Lockout Tagout

Traditional Lockout Tagout (LOTO) provides robust mechanical isolation, ensuring equipment cannot be energized during maintenance, which significantly reduces the risk of accidental startup. However, its reliance on physical tags and locks can lead to human errors, such as improper application or failure to update status, limiting real-time visibility and communication. Unlike digital permit-to-work systems, LOTO lacks centralized monitoring and automated compliance tracking, making auditability and coordination across multiple contractors more challenging.

Benefits and Challenges of Digital Permit to Work Systems

Digital Permit to Work systems enhance safety by providing real-time monitoring, reducing human error, and enabling streamlined communication across teams during hazardous operations. These systems offer benefits such as instant accessibility, automated compliance tracking, and reduced paperwork, improving overall operational efficiency. Challenges include the need for robust cybersecurity measures, initial implementation costs, and the requirement for comprehensive training to ensure user adoption and system effectiveness.

Integration of LOTO and Digital PTW in Modern Safety Programs

Integration of Lockout Tagout (LOTO) procedures with Digital Permit to Work (PTW) systems enhances real-time monitoring and compliance tracking in modern safety programs. Digital PTW platforms streamline issuance, verification, and audit trails of LOTO permits, reducing human error and ensuring hazardous energy isolation before maintenance activities. This synergy improves worker safety by providing centralized control and instant communication across teams, aligning with regulatory standards such as OSHA and ISO 45001.

Case Studies: Real-world Applications and Outcomes

Case studies reveal that Lockout Tagout (LOTO) procedures have significantly reduced workplace injuries by isolating hazardous energy sources during maintenance, with many manufacturing plants reporting a 45% decrease in accidents. Digital Permit to Work systems integrate real-time data and automated workflows, enhancing compliance and communication, as evidenced by a chemical plant that achieved a 30% improvement in permit processing time and zero permit-related incidents over two years. Combining LOTO with digital permits offers comprehensive safety management, exemplified by an oil refinery that saw a 60% reduction in unscheduled downtime and improved audit scores.

Digital Transformation: Moving from Paper-based to Electronic Systems

Digital transformation in safety protocols shifts lockout tagout processes from paper-based methods to electronic systems, enhancing real-time monitoring and compliance tracking. Electronic permit to work systems reduce human error, streamline communication, and ensure audit trails for critical safety operations. This transition optimizes risk management by enabling faster updates and centralized data access in industrial environments.

Safety Performance: Comparing Incident Reduction and Compliance

Lockout Tagout (LOTO) procedures significantly reduce workplace incidents by physically isolating energy sources, with studies showing up to a 60% decrease in accidental startups during maintenance. Digital Permit to Work systems enhance compliance monitoring through real-time data tracking and automated alerts, leading to a 40% improvement in adherence to safety protocols. Combining LOTO with digital permits creates a synergistic effect, driving incident reduction rates beyond traditional methods by integrating physical safeguards with digital oversight.

Future Trends: Innovations in Isolation and Permit Management

Lockout Tagout procedures are increasingly integrated with digital permit to work systems, enhancing real-time monitoring and compliance tracking. Innovations such as IoT-enabled lockout devices and automated permit approvals improve isolation accuracy and reduce human error. Future trends emphasize seamless connectivity and data analytics to optimize safety protocols and workforce accountability.

Related Important Terms

Electronic Lockout Tagout (e-LOTO)

Electronic Lockout Tagout (e-LOTO) systems enhance workplace safety by digitizing traditional Lockout Tagout procedures, providing real-time tracking and remote authorization to prevent accidental equipment energization. Compared to conventional methods, e-LOTO integrates with Digital Permit to Work platforms, streamlining compliance, reducing human error, and improving auditability for hazardous energy control.

Digital Isolation Management

Digital Isolation Management enhances Lockout Tagout protocols by integrating real-time monitoring, automated permit issuance, and compliance tracking to reduce human error and increase workplace safety. This technology-driven approach streamlines Digital Permit to Work processes, ensuring precise control of hazardous energy isolation and improving overall operational efficiency.

Permit-to-Work (PtW) Automation

Digital Permit-to-Work (PtW) automation enhances traditional Lockout Tagout (LOTO) processes by streamlining hazard identification, authorization, and compliance tracking through real-time data integration and mobile access. Leveraging automated workflows and audit trails, PtW systems reduce human error, improve worker safety, and facilitate regulatory compliance across complex industrial operations.

Smart Lockout Devices

Smart lockout devices enhance traditional Lockout Tagout procedures by integrating digital permit-to-work systems, enabling real-time monitoring and remote control of hazardous energy sources. These advanced devices reduce human error, increase compliance with safety regulations, and streamline workflow efficiency in industrial environments.

Connected Worker Platforms

Lockout Tagout (LOTO) procedures ensure worker safety by physically isolating hazardous energy sources, while Digital Permit to Work systems streamline authorization processes within Connected Worker Platforms, enhancing real-time compliance and communication. Integrating LOTO with digital permits improves operational efficiency and reduces human error by providing instant access to safety protocols and worker status.

Cloud-based Safety Permitting

Cloud-based Safety Permitting enhances traditional Lockout Tagout procedures by enabling real-time monitoring, remote authorization, and streamlined compliance documentation, significantly reducing downtime and human error. Digital Permit to Work systems integrate with Lockout Tagout protocols to provide centralized control, automated audit trails, and instant notifications, improving overall workplace safety and operational efficiency.

Real-time Permit Visibility

Digital Permit to Work systems provide real-time permit visibility through centralized dashboards, enabling instant tracking and status updates of lockout tagout procedures. This enhanced transparency reduces human error, improves compliance, and accelerates decision-making compared to traditional Lockout Tagout methods reliant on physical tags and manual logs.

Remote Energy Isolation

Lockout Tagout (LOTO) procedures ensure physical isolation of hazardous energy sources through mechanical devices to prevent accidental startup, while Digital Permit to Work (dPTW) systems enhance safety by enabling remote energy isolation and real-time monitoring, reducing human error and improving compliance. Remote energy isolation via dPTW integrates IoT sensors and automated controls, providing precise control and documentation for lockout-tagout processes, thereby increasing operational efficiency and safety in high-risk environments.

Mobile Permit Approvals

Lockout Tagout procedures ensure physical isolation of hazardous energy, while Digital Permit to Work systems streamline mobile permit approvals, enhancing efficiency and real-time compliance tracking. Mobile permit approvals enable instant authorization and auditability, reducing downtime and human error in high-risk work environments.

RFID-enabled Lockout Systems

RFID-enabled Lockout Tagout systems enhance safety by providing real-time identification and status verification of locked-out equipment, significantly reducing human error and unauthorized access. Digital Permit to Work platforms integrate RFID technology to automate compliance tracking, improve auditability, and ensure strict adherence to safety protocols in hazardous environments.

Lockout Tagout vs Digital Permit to Work Infographic

industrydif.com

industrydif.com