Manual inspections of pet safety involve close, hands-on evaluation that ensures detailed observation of small hazards like loose wires or toxic plants. Drone-based safety inspections offer a faster, broader overview of larger areas, efficiently identifying structural risks and inaccessible spots where pets might get trapped. Combining both methods provides thorough protection by merging precise detail with extensive reach.

Table of Comparison

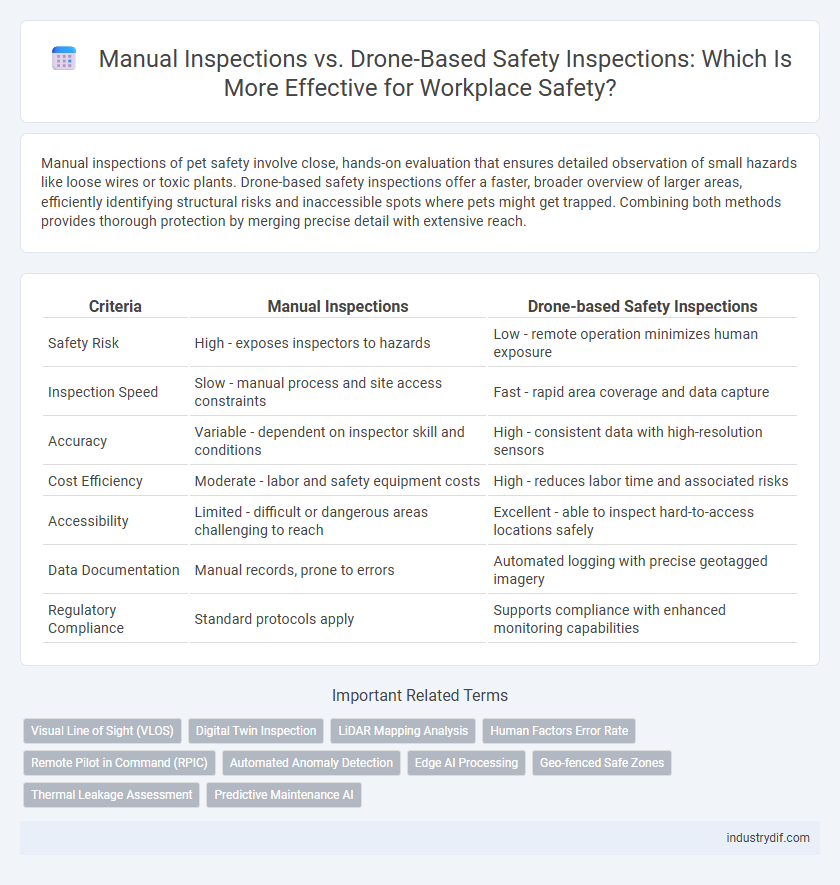

| Criteria | Manual Inspections | Drone-based Safety Inspections |

|---|---|---|

| Safety Risk | High - exposes inspectors to hazards | Low - remote operation minimizes human exposure |

| Inspection Speed | Slow - manual process and site access constraints | Fast - rapid area coverage and data capture |

| Accuracy | Variable - dependent on inspector skill and conditions | High - consistent data with high-resolution sensors |

| Cost Efficiency | Moderate - labor and safety equipment costs | High - reduces labor time and associated risks |

| Accessibility | Limited - difficult or dangerous areas challenging to reach | Excellent - able to inspect hard-to-access locations safely |

| Data Documentation | Manual records, prone to errors | Automated logging with precise geotagged imagery |

| Regulatory Compliance | Standard protocols apply | Supports compliance with enhanced monitoring capabilities |

Introduction to Manual vs Drone-based Safety Inspections

Manual safety inspections rely on human inspectors physically examining sites, often facing limitations such as accessibility challenges and increased risk of injury. Drone-based safety inspections utilize advanced aerial technology to capture high-resolution images and data, enabling rapid assessment of hazardous or hard-to-reach areas with enhanced precision. This transition from manual to drone-based methods significantly improves inspection efficiency, reduces human risk, and provides comprehensive, real-time safety insights.

Key Differences in Inspection Methodologies

Manual inspections rely on direct human observation, enabling tactile assessment and immediate judgment in complex environments. Drone-based safety inspections utilize advanced sensors and aerial imaging technology to access hard-to-reach areas, providing high-resolution data and reducing human exposure to hazardous conditions. Drones streamline the inspection process by capturing real-time visual and thermal information, enhancing accuracy while minimizing time and labor costs compared to traditional methods.

Accuracy and Data Collection Capabilities

Drone-based safety inspections deliver superior accuracy through high-resolution imaging and real-time data transmission, enabling precise identification of hazards often missed during manual inspections. Advanced sensors and AI-powered analytics enhance data collection capabilities, capturing comprehensive environmental variables and structural details more efficiently. Manual inspections, while reliable, are limited by human error and accessibility challenges, resulting in less thorough data compared to drone technology.

Safety Risk Mitigation: Human vs Drone

Manual inspections expose workers to significant safety risks, including falls, electrical hazards, and limited access to dangerous areas. Drone-based safety inspections mitigate these risks by enabling remote data collection in hazardous or hard-to-reach locations, reducing the likelihood of accidents and injuries. Utilizing drones enhances overall safety protocols by minimizing direct human exposure to potentially dangerous environments during inspection tasks.

Cost Efficiency and Operational Expenses

Manual inspections often incur higher operational expenses due to labor-intensive processes, extended inspection times, and the need for specialized safety equipment, which collectively increase overall costs. Drone-based safety inspections significantly reduce labor costs and time on-site, enhancing cost efficiency by enabling rapid data collection and real-time analysis while minimizing manual risk exposure. Investments in drone technology typically yield lower long-term operational expenses, improved inspection accuracy, and minimized downtime, driving greater economic benefits for safety management.

Inspection Speed and Downtime Reduction

Drone-based safety inspections significantly increase inspection speed by capturing high-resolution data quickly over large or hard-to-reach areas, reducing the need for manual access. This rapid data collection minimizes operational downtime compared to manual inspections that require extensive setup and physical presence. Organizations adopting drones report up to 70% faster inspections and a corresponding decrease in safety-related downtime, optimizing overall productivity.

Accessibility to Hazardous or Hard-to-Reach Areas

Drone-based safety inspections significantly enhance accessibility to hazardous or hard-to-reach areas such as high-rise structures, confined spaces, and unstable terrain, reducing the need for personnel to enter dangerous environments. Manual inspections often require extensive safety measures, scaffolding, and time-consuming preparations, increasing both risk and operational costs. Utilizing drones equipped with high-resolution cameras and thermal sensors enables rapid, precise assessments while minimizing human exposure to potential hazards.

Regulatory Compliance and Legal Considerations

Manual inspections require strict adherence to OSHA regulations and often involve detailed record-keeping to ensure legal compliance, but they can be limited by human error and physical safety risks. Drone-based safety inspections must comply with FAA regulations, including operator certification and flight restrictions, while offering enhanced data accuracy and reduced liability through comprehensive digital audit trails. Integrating drone technology with established safety protocols not only streamlines regulatory reporting but also minimizes legal exposure related to onsite hazards and inspection documentation.

Environmental Impact and Sustainability

Manual inspections often require significant travel and use of vehicles, leading to higher carbon emissions and environmental disturbance. Drone-based safety inspections reduce the need for onsite human presence, minimizing fuel consumption and lowering the overall carbon footprint. This technology promotes sustainability by enabling frequent, accurate assessments with minimal environmental disruption.

Future Trends in Industrial Safety Inspections

Drone-based safety inspections are rapidly transforming industrial safety protocols by enabling real-time data collection and reducing human exposure to hazardous environments. Manual inspections, while still essential for detailed assessments, are increasingly supplemented by drones equipped with advanced sensors and AI-driven analytics, enhancing accuracy and efficiency. Future trends indicate a seamless integration of drone technology with IoT systems and predictive maintenance software, driving proactive safety management and minimizing risk in industrial settings.

Related Important Terms

Visual Line of Sight (VLOS)

Manual inspections rely heavily on Visual Line of Sight (VLOS) for accurate assessment, limiting access to hazardous or hard-to-reach areas and increasing risk to inspectors. Drone-based safety inspections enhance VLOS by providing aerial perspectives and real-time video feeds, enabling safer, more comprehensive evaluations without compromising operator safety.

Digital Twin Inspection

Digital Twin Inspection enhances safety by providing precise, real-time 3D models of infrastructure, enabling thorough analysis without physical risks associated with manual inspections. Drone-based safety inspections integrated with digital twin technology streamline data collection and improve accuracy, reducing human error and increasing operational efficiency.

LiDAR Mapping Analysis

Manual inspections rely heavily on visual assessments, which can miss critical details in complex environments, whereas drone-based safety inspections equipped with LiDAR mapping provide precise 3D spatial data for comprehensive hazard identification. LiDAR technology enhances accuracy in detecting structural anomalies and potential safety risks by generating high-resolution point clouds, enabling faster and safer analysis compared to traditional methods.

Human Factors Error Rate

Drone-based safety inspections significantly reduce human factors error rates compared to manual inspections by minimizing fatigue, cognitive overload, and physical hazards for workers. Automated data capture and real-time analytics from drones enhance accuracy and consistency, leading to safer and more reliable inspection outcomes.

Remote Pilot in Command (RPIC)

Remote Pilot in Command (RPIC) plays a critical role in drone-based safety inspections by ensuring compliance with aviation regulations and maintaining operational control to prevent accidents. Unlike manual inspections, RPIC-controlled drones provide enhanced safety monitoring capabilities in hazardous environments, reducing human exposure to potential risks.

Automated Anomaly Detection

Drone-based safety inspections leverage automated anomaly detection powered by AI algorithms to identify hazards with higher accuracy and speed than manual inspections. This technology reduces human error, enhances data consistency, and enables real-time risk assessment in hazardous environments.

Edge AI Processing

Manual inspections rely heavily on human judgment and can be time-consuming, while drone-based safety inspections equipped with Edge AI processing enable real-time data analysis at the inspection site, significantly reducing response times and enhancing hazard detection accuracy. Edge AI-powered drones process visual and sensory data on-device, minimizing latency and reliance on network connectivity, which ensures continuous monitoring and immediate identification of safety risks in complex industrial environments.

Geo-fenced Safe Zones

Geo-fenced safe zones enhance drone-based safety inspections by automatically restricting drone movement to designated areas, reducing human error and safety risks present in manual inspections. This technology enables precise monitoring and rapid identification of hazards within predefined perimeters, significantly improving site safety compliance and efficiency.

Thermal Leakage Assessment

Thermal leakage assessment using drone-based safety inspections enables precise detection of heat loss and energy inefficiencies in hard-to-reach areas, significantly reducing human exposure to hazardous environments compared to manual inspections. Advanced thermal imaging sensors on drones provide faster data collection and real-time analytics, enhancing overall accuracy and operational safety during facility audits.

Predictive Maintenance AI

Predictive Maintenance AI integrates real-time data from drone-based safety inspections to identify potential equipment failures before they occur, enabling proactive maintenance and reducing downtime. Manual inspections limit the scope and frequency of data collection, hindering early detection capabilities and increasing the risk of unexpected safety hazards.

Manual Inspections vs Drone-based Safety Inspections Infographic

industrydif.com

industrydif.com