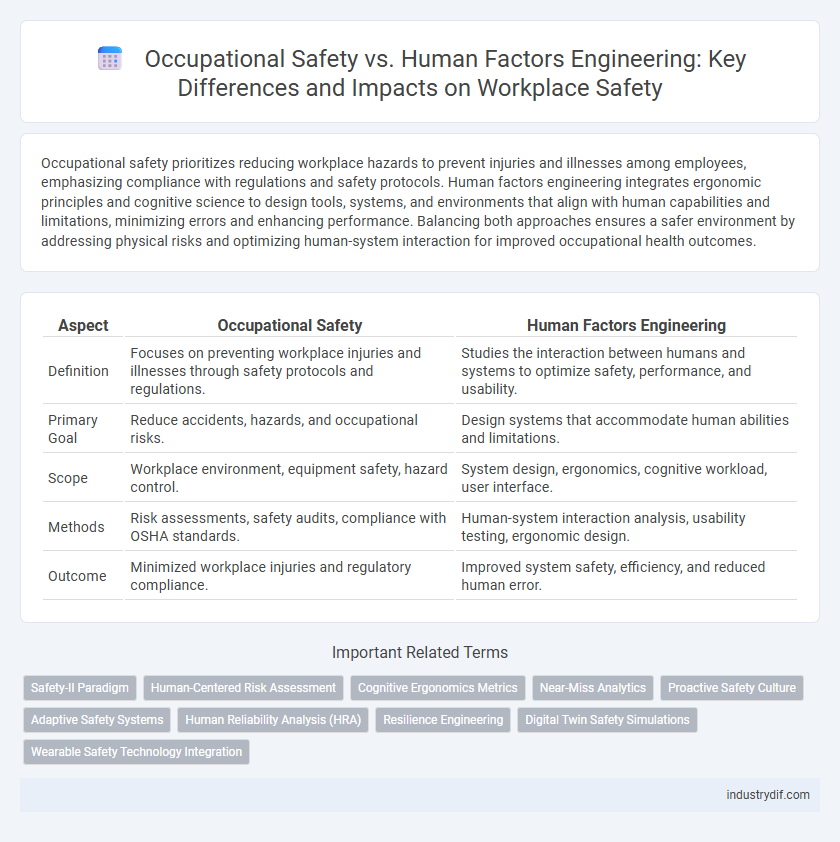

Occupational safety prioritizes reducing workplace hazards to prevent injuries and illnesses among employees, emphasizing compliance with regulations and safety protocols. Human factors engineering integrates ergonomic principles and cognitive science to design tools, systems, and environments that align with human capabilities and limitations, minimizing errors and enhancing performance. Balancing both approaches ensures a safer environment by addressing physical risks and optimizing human-system interaction for improved occupational health outcomes.

Table of Comparison

| Aspect | Occupational Safety | Human Factors Engineering |

|---|---|---|

| Definition | Focuses on preventing workplace injuries and illnesses through safety protocols and regulations. | Studies the interaction between humans and systems to optimize safety, performance, and usability. |

| Primary Goal | Reduce accidents, hazards, and occupational risks. | Design systems that accommodate human abilities and limitations. |

| Scope | Workplace environment, equipment safety, hazard control. | System design, ergonomics, cognitive workload, user interface. |

| Methods | Risk assessments, safety audits, compliance with OSHA standards. | Human-system interaction analysis, usability testing, ergonomic design. |

| Outcome | Minimized workplace injuries and regulatory compliance. | Improved system safety, efficiency, and reduced human error. |

Understanding Occupational Safety: Key Principles

Occupational safety centers on identifying and controlling workplace hazards to prevent accidents and injuries. Key principles include hazard recognition, risk assessment, and the implementation of effective safety protocols and training programs. Human factors engineering complements these efforts by designing systems and environments that account for human capabilities and limitations, thereby enhancing overall safety performance.

Defining Human Factors Engineering in the Workplace

Human Factors Engineering in the workplace focuses on designing systems, tools, and environments that align with human abilities and limitations to enhance safety and performance. This discipline integrates principles from psychology, engineering, and ergonomics to reduce errors, prevent accidents, and improve overall occupational safety. By optimizing human-system interaction, organizations can minimize workplace hazards and promote a safer, more efficient work environment.

Core Differences Between Occupational Safety and Human Factors Engineering

Occupational Safety primarily focuses on minimizing workplace hazards through compliance with safety regulations, risk assessments, and protective measures to prevent accidents and injuries. Human Factors Engineering emphasizes designing systems, tools, and environments to optimize human performance, reduce errors, and enhance overall safety by considering cognitive, physical, and organizational factors. The core difference lies in Occupational Safety targeting hazard control and regulatory adherence, while Human Factors Engineering centers on integrating human capabilities and limitations into system design for improved safety outcomes.

Historical Evolution of Safety and Human Factors Approaches

The historical evolution of occupational safety has transitioned from rudimentary hazard control to incorporating sophisticated human factors engineering principles, emphasizing the interaction between workers and their environments. Early safety approaches focused primarily on physical protections, while modern human factors engineering integrates cognitive, environmental, and organizational aspects to reduce errors and enhance system reliability. This shift reflects a deeper understanding of human behavior, ergonomics, and system design in preventing workplace injuries and improving overall safety performance.

The Role of Human Behavior in Occupational Safety

Human behavior critically influences occupational safety by shaping risk perception, compliance with safety protocols, and decision-making processes in hazardous environments. Human Factors Engineering systematically analyzes these behavioral aspects to design work systems and tools that minimize errors and enhance safety performance. Integrating behavioral insights with ergonomic solutions reduces workplace accidents and promotes a culture of proactive safety management.

Risk Assessment: Safety Protocols vs. Human-Centered Design

Occupational safety relies heavily on risk assessment to develop safety protocols that mitigate hazards through standardized procedures and compliance measures. Human Factors Engineering integrates risk assessment by emphasizing human-centered design, which anticipates user behavior and ergonomic factors to prevent accidents at the source. Combining both approaches enhances workplace safety by addressing both environmental risks and human interactions with systems.

Integrating Human Factors into Traditional Safety Programs

Integrating human factors engineering into traditional occupational safety programs enhances hazard identification by addressing cognitive, physical, and organizational elements that influence worker behavior. This approach reduces workplace incidents by designing systems and processes tailored to human capabilities and limitations, promoting safer interactions with machinery and environments. Emphasizing ergonomic design and error reduction strategies fosters a proactive safety culture that aligns with industry standards such as OSHA and ISO 45001.

Case Studies: Success Stories in Safety and Human Factors Collaboration

Case studies in occupational safety reveal significant improvements when integrated with human factors engineering, demonstrating reduced workplace incidents by up to 40%. Collaborative approaches emphasize ergonomic design and behavioral analysis, leading to enhanced safety protocols and employee well-being across industries. These success stories highlight measurable outcomes such as decreased injury rates and increased compliance with safety standards.

Regulatory Standards for Occupational Safety and Human Factors

Occupational safety regulatory standards such as OSHA's General Industry Standards (29 CFR 1910) ensure workplace hazard identification, risk assessment, and injury prevention, mandating employer compliance for worker protection. Human Factors Engineering integrates regulatory frameworks like ISO 9241 and ANSI/HFES standards to optimize system design for human interaction, reducing errors and enhancing safety performance. Both domains emphasize compliance with safety standards, but occupational safety focuses on physical hazard controls while human factors prioritize ergonomic and cognitive considerations.

Future Trends: Merging Occupational Safety with Human Factors Engineering

Future trends in occupational safety emphasize integrating human factors engineering principles to enhance workplace design and reduce injury risks. By leveraging ergonomic data and cognitive workload analysis, organizations can create safer, more efficient environments that anticipate human limitations and behaviors. This convergence promotes proactive hazard identification and fosters adaptive safety systems tailored to evolving technological and operational contexts.

Related Important Terms

Safety-II Paradigm

The Safety-II paradigm emphasizes understanding how everyday work succeeds by studying human factors engineering, which focuses on designing systems that accommodate human variability and enhance resilience. Occupational safety traditionally centers on preventing failures and accidents, while Safety-II promotes proactive approaches that support workers' adaptability to complex environments.

Human-Centered Risk Assessment

Human-Centered Risk Assessment integrates Human Factors Engineering principles to identify and mitigate safety hazards by analyzing human behaviors, capabilities, and limitations within occupational environments. This approach enhances occupational safety by designing systems and workflows that prioritize human well-being and reduce the likelihood of errors and accidents.

Cognitive Ergonomics Metrics

Occupational Safety integrates Cognitive Ergonomics Metrics to enhance worker performance by minimizing mental workload, reducing errors, and improving decision-making processes in high-risk environments. Human Factors Engineering leverages cognitive load assessments, situational awareness indexes, and reaction time measurements to design safer systems that align with human cognitive capabilities.

Near-Miss Analytics

Near-Miss Analytics integrates Occupational Safety data with Human Factors Engineering principles to proactively identify potential hazards before incidents occur, enhancing workplace injury prevention. Leveraging real-time near-miss reporting and ergonomic assessments, organizations can implement targeted interventions that reduce human error and improve overall safety performance.

Proactive Safety Culture

Occupational Safety emphasizes regulatory compliance and hazard prevention to reduce workplace accidents, while Human Factors Engineering focuses on designing systems that align with human capabilities and limitations, fostering a proactive safety culture through ergonomic solutions and error mitigation. Integrating these approaches enhances proactive safety culture by anticipating risks and promoting continuous improvement in worker well-being and system reliability.

Adaptive Safety Systems

Adaptive Safety Systems integrate human factors engineering principles to enhance occupational safety by dynamically responding to workers' behaviors and environmental conditions. These systems leverage real-time data and contextual awareness to minimize human error, optimize safety protocols, and reduce workplace accidents effectively.

Human Reliability Analysis (HRA)

Human Reliability Analysis (HRA) plays a critical role in Human Factors Engineering by systematically evaluating the likelihood of human errors within complex occupational safety systems. Integrating HRA into safety management enhances hazard identification and mitigates risks by addressing cognitive and behavioral factors influencing worker performance.

Resilience Engineering

Occupational safety prioritizes hazard identification and risk mitigation to prevent workplace injuries, while human factors engineering emphasizes designing systems that accommodate human capabilities and limitations. Resilience engineering enhances both by focusing on adaptive capacity and recovery from unexpected disruptions, ensuring sustained safety performance under dynamic conditions.

Digital Twin Safety Simulations

Occupational safety benefits significantly from integrating Human Factors Engineering through digital twin safety simulations, which create virtual replicas of work environments to identify and mitigate hazards before real-world implementation. These simulations enhance risk assessment accuracy and improve worker safety by modeling human-machine interactions and predicting potential failures in complex industrial systems.

Wearable Safety Technology Integration

Integrating wearable safety technology in occupational safety enhances hazard detection and real-time monitoring, aligning with human factors engineering principles to improve worker ergonomics and reduce cognitive overload. This synergy optimizes safety outcomes by adapting technology to human behavior and environmental conditions, ensuring proactive risk management.

Occupational Safety vs Human Factors Engineering Infographic

industrydif.com

industrydif.com