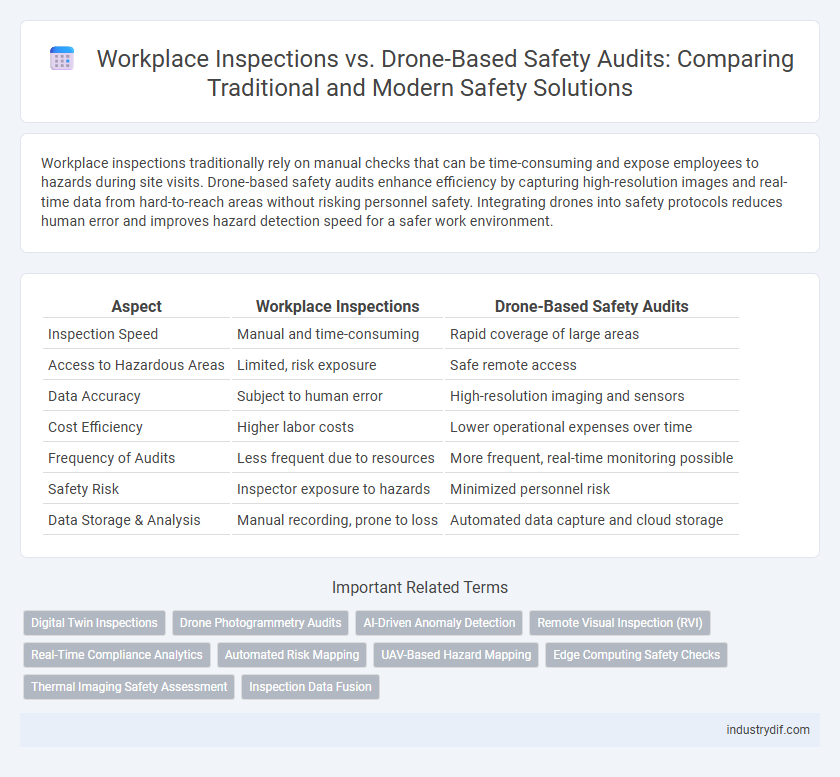

Workplace inspections traditionally rely on manual checks that can be time-consuming and expose employees to hazards during site visits. Drone-based safety audits enhance efficiency by capturing high-resolution images and real-time data from hard-to-reach areas without risking personnel safety. Integrating drones into safety protocols reduces human error and improves hazard detection speed for a safer work environment.

Table of Comparison

| Aspect | Workplace Inspections | Drone-Based Safety Audits |

|---|---|---|

| Inspection Speed | Manual and time-consuming | Rapid coverage of large areas |

| Access to Hazardous Areas | Limited, risk exposure | Safe remote access |

| Data Accuracy | Subject to human error | High-resolution imaging and sensors |

| Cost Efficiency | Higher labor costs | Lower operational expenses over time |

| Frequency of Audits | Less frequent due to resources | More frequent, real-time monitoring possible |

| Safety Risk | Inspector exposure to hazards | Minimized personnel risk |

| Data Storage & Analysis | Manual recording, prone to loss | Automated data capture and cloud storage |

Introduction to Workplace Safety Assessments

Workplace safety assessments are essential for identifying hazards and ensuring regulatory compliance in various industries. Traditional workplace inspections involve physical walkthroughs by safety professionals, while drone-based safety audits utilize unmanned aerial vehicles to access hard-to-reach areas and capture real-time data. Incorporating drone technology enhances precision, reduces inspection time, and improves overall risk management strategies.

Traditional Workplace Inspections: Methods and Limitations

Traditional workplace inspections rely heavily on manual walkthroughs and checklists to identify safety hazards, which can be time-consuming and prone to human error. Inspectors may miss hard-to-reach areas or subtle risk factors, limiting the comprehensiveness of the audit. These methods often struggle to provide real-time data and detailed analysis necessary for proactive safety management.

The Rise of Drone-Based Safety Audits

Drone-based safety audits revolutionize workplace inspections by providing high-resolution aerial data, identifying hazards in hard-to-reach areas, and reducing human risk exposure. These audits enhance accuracy through real-time data analysis and integrate advanced sensors like thermal imaging for comprehensive safety assessments. Companies adopting drones report faster identification of safety violations, increased inspection frequency, and improved compliance with industry safety standards.

Efficiency Comparison: Human Inspections vs Drone Audits

Workplace inspections conducted by humans typically require more time and resources due to physical access limitations and manual data recording. Drone-based safety audits provide enhanced efficiency by quickly capturing comprehensive visual data in hard-to-reach or hazardous areas, reducing inspection time by up to 70%. The integration of drones with AI analytics accelerates hazard detection and reporting, streamlining safety compliance and minimizing operational downtime.

Data Accuracy and Documentation in Safety Evaluations

Workplace inspections conducted traditionally rely on manual observation, which can introduce human error and inconsistencies in safety evaluations. Drone-based safety audits enhance data accuracy by capturing high-resolution images and real-time video, enabling precise hazard identification and thorough documentation. This technology supports comprehensive safety records, facilitating better compliance with regulatory standards and more effective risk management.

Worker Safety Risks and Exposure in Both Methods

Workplace inspections conducted manually often expose workers to hazards such as falls, chemical exposure, and confined space entry, increasing the risk of injury during the audit process. Drone-based safety audits minimize worker exposure by remotely capturing high-resolution imagery and real-time data in hazardous or hard-to-reach areas, significantly reducing direct contact with dangerous environments. Data from OSHA indicates drone inspections reduce on-site injuries by up to 30%, emphasizing their effectiveness in mitigating workplace safety risks.

Regulatory Compliance in Drone and Traditional Audits

Workplace inspections and drone-based safety audits both aim to ensure regulatory compliance by identifying hazards and enforcing safety standards. Traditional inspections rely on manual evaluations in accordance with OSHA and other regulatory frameworks, while drone-based audits enhance compliance by providing comprehensive, real-time data and accessing hard-to-reach areas. Regulatory agencies increasingly recognize drones as a valid tool for safety audits, provided operators follow FAA regulations and privacy laws, ensuring accurate and efficient workplace safety assessments.

Cost Analysis: Manual Inspections vs Drone Implementation

Manual workplace inspections typically incur higher labor costs and longer timeframes due to the need for on-site personnel to conduct thorough evaluations. Drone-based safety audits offer a cost-efficient alternative by reducing labor expenses and minimizing downtime through rapid data collection and automated reporting. Initial drone implementation involves upfront investment in equipment and training, but long-term savings and improved inspection accuracy contribute to a favorable return on investment.

Future Trends in Workplace Safety Auditing Technology

Workplace safety inspections are evolving rapidly with the integration of drone-based safety audits, which offer enhanced accessibility to hard-to-reach areas and real-time data collection. Advanced AI-driven analytics paired with high-resolution drone imagery improve hazard detection precision and predictive safety management. Future trends indicate widespread adoption of autonomous drones equipped with thermal and lidar sensors, transforming workplace safety auditing into a continuous, data-centric process.

Choosing the Right Approach: Factors to Consider

Workplace inspections require thorough human observation to identify hazards, while drone-based safety audits leverage aerial technology for access to hard-to-reach areas and real-time data capture. Choosing the right approach depends on factors such as site complexity, the presence of confined spaces, budget constraints, and the need for high-resolution imaging or immediate hazard detection. Evaluating operational risks, regulatory compliance, and available technology integration ensures optimal safety management tailored to the specific work environment.

Related Important Terms

Digital Twin Inspections

Digital Twin Inspections revolutionize workplace safety by creating precise virtual replicas of physical environments, enabling real-time hazard identification and risk assessment without on-site disruptions. Integrating drone-based safety audits with digital twins enhances accuracy and efficiency, providing dynamic, data-driven insights that surpass traditional inspection methods.

Drone Photogrammetry Audits

Drone photogrammetry audits enhance workplace inspections by capturing high-resolution, georeferenced images that provide precise spatial data for identifying safety hazards and structural anomalies. This technology reduces human error, accelerates data collection, and enables thorough analysis of hard-to-reach areas, improving overall safety compliance and risk management.

AI-Driven Anomaly Detection

Workplace inspections enhanced by AI-driven anomaly detection enable real-time identification of safety hazards, significantly reducing human error and increasing efficiency compared to traditional methods. Drone-based safety audits leverage AI algorithms to analyze high-resolution imagery, promptly detecting irregularities such as structural weaknesses or unsafe conditions in challenging environments.

Remote Visual Inspection (RVI)

Workplace inspections utilize on-site evaluations to identify safety hazards, whereas drone-based safety audits leverage Remote Visual Inspection (RVI) technology to access hard-to-reach areas, enhancing hazard detection efficiency and worker safety. RVI enables high-resolution video and imaging, reducing human exposure to dangerous environments and providing comprehensive, real-time data for risk assessment.

Real-Time Compliance Analytics

Workplace inspections provide manual observation data, while drone-based safety audits deliver real-time compliance analytics through high-resolution sensors and AI-powered recognition, enabling immediate identification of hazards and regulatory violations. This advanced technology enhances safety protocols by continuously monitoring environments and generating actionable insights for rapid intervention.

Automated Risk Mapping

Workplace inspections integrated with drone-based safety audits enhance automated risk mapping by providing real-time, high-resolution data that identifies hazards with greater accuracy and speed. Drones equipped with advanced sensors capture comprehensive environmental metrics, enabling dynamic risk assessments and more effective mitigation strategies in complex industrial settings.

UAV-Based Hazard Mapping

UAV-based hazard mapping enhances workplace safety by providing comprehensive, high-resolution aerial data that identifies potential risks inaccessible during traditional inspections. This technology enables real-time analysis, improving accuracy and efficiency in detecting hazards like structural weaknesses, chemical spills, or fire risks.

Edge Computing Safety Checks

Edge computing safety checks enhance workplace inspections by enabling real-time data processing and immediate hazard detection on-site, reducing reliance on remote servers and minimizing latency. Drone-based safety audits integrated with edge computing facilitate rapid identification of safety risks in hazardous or hard-to-reach areas, improving accuracy and response time in industrial environments.

Thermal Imaging Safety Assessment

Workplace inspections with traditional methods often miss critical heat anomalies that drone-based safety audits equipped with thermal imaging can detect, enhancing early identification of electrical faults, overheating machinery, and fire hazards. Drone thermal imaging provides precise, real-time temperature mapping, improving hazard assessment accuracy and enabling proactive maintenance that significantly reduces workplace safety risks.

Inspection Data Fusion

Workplace inspections combined with drone-based safety audits leverage inspection data fusion to enhance hazard detection accuracy and reduce blind spots by integrating visual, thermal, and sensor data in real-time. This data fusion enables comprehensive safety assessments, facilitating proactive risk mitigation and ensuring regulatory compliance through detailed, multi-dimensional analysis.

Workplace Inspections vs Drone-Based Safety Audits Infographic

industrydif.com

industrydif.com