Manual Lockout-Tagout requires physically securing energy-isolating devices to ensure worker safety during equipment maintenance, relying heavily on human diligence and proper training. Digital Lockout-Tagout integrates electronic controls and software to automate and monitor lockout procedures, reducing human error and providing real-time status updates. Choosing between manual and digital systems depends on factors like facility size, complexity, and the need for enhanced compliance tracking.

Table of Comparison

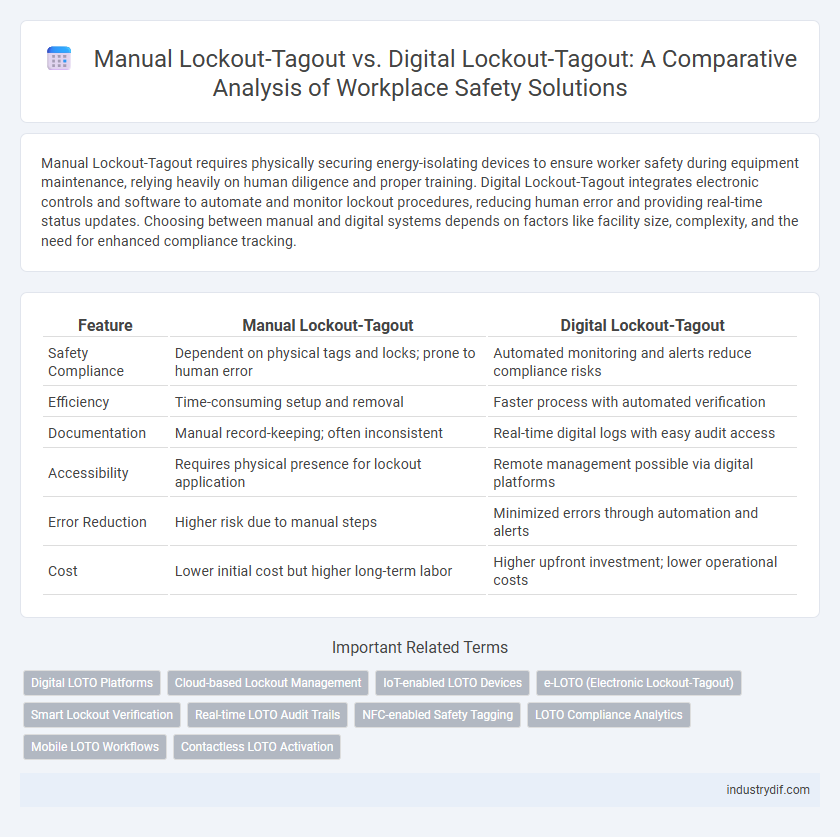

| Feature | Manual Lockout-Tagout | Digital Lockout-Tagout |

|---|---|---|

| Safety Compliance | Dependent on physical tags and locks; prone to human error | Automated monitoring and alerts reduce compliance risks |

| Efficiency | Time-consuming setup and removal | Faster process with automated verification |

| Documentation | Manual record-keeping; often inconsistent | Real-time digital logs with easy audit access |

| Accessibility | Requires physical presence for lockout application | Remote management possible via digital platforms |

| Error Reduction | Higher risk due to manual steps | Minimized errors through automation and alerts |

| Cost | Lower initial cost but higher long-term labor | Higher upfront investment; lower operational costs |

Introduction to Lockout-Tagout (LOTO) Systems

Lockout-Tagout (LOTO) systems are critical safety procedures designed to prevent accidental machine startup during maintenance, protecting workers from hazardous energy releases. Manual LOTO involves physically isolating energy sources using locks and tags, ensuring equipment remains inoperative until maintenance is complete. Digital LOTO enhances this process by integrating electronic controls and software management, improving compliance tracking and reducing human error in industrial safety protocols.

Manual LOTO: Definition and Core Principles

Manual Lockout-Tagout (LOTO) is a safety procedure that involves physically isolating hazardous energy sources by applying locks and tags to equipment to prevent accidental startup during maintenance. Core principles include energy isolation, authorization, verification of de-energization, and communication, ensuring that only trained personnel control lockout devices. This method reduces workplace accidents by enforcing strict control over machinery and electrical systems during servicing.

Digital LOTO: Emerging Technologies and Methods

Digital Lockout-Tagout (LOTO) leverages advanced technologies such as IoT sensors, RFID tags, and cloud-based platforms to enhance safety by providing real-time monitoring and remote control of energy isolation. These systems reduce human error, increase compliance through automated verification, and enable centralized data management for audits and reporting. Emerging methods integrate AI-driven analytics to predict potential hazards and optimize maintenance schedules, significantly improving workplace safety and operational efficiency.

Compliance and Regulatory Standards

Manual Lockout-Tagout systems comply with OSHA standards outlined in 29 CFR 1910.147, requiring physical isolation of energy sources to prevent hazardous energy release during maintenance. Digital Lockout-Tagout solutions enhance compliance by providing automated tracking, audit trails, and real-time status updates, aligning with regulatory requirements while reducing human error. Both approaches must meet ANSI/ASSE Z244.1 standards to ensure effective control of hazardous energy and maintain workplace safety.

Human Error: Risks in Manual vs Digital Approaches

Manual Lockout-Tagout procedures are prone to human error due to reliance on physical tags and locks that can be improperly applied or overlooked, increasing the risk of accidental machine startup and workplace injuries. Digital Lockout-Tagout systems reduce these risks by automating lockout verification, providing real-time status updates, and incorporating user authentication to ensure compliance and accountability. Studies show that digital solutions can lower human error rates by up to 60%, significantly enhancing overall safety in industrial environments.

Documentation and Audit Trails

Manual Lockout-Tagout relies on physical tags and handwritten logs, which can lead to inconsistencies and difficulty in maintaining precise documentation. Digital Lockout-Tagout systems automatically capture real-time data, providing detailed audit trails and ensuring compliance with safety regulations like OSHA standards. Enhanced traceability in digital solutions minimizes human error and streamlines safety audits, improving overall workplace safety management.

Training Requirements for Manual and Digital LOTO

Training requirements for Manual Lockout-Tagout (LOTO) emphasize hands-on instruction in physical device usage, hazard recognition, and compliance with OSHA standards to ensure proper isolation of energy sources. Digital Lockout-Tagout systems demand additional training on software interfaces, real-time monitoring tools, and cybersecurity protocols to manage electronic controls effectively. Both methods require comprehensive understanding of safety procedures, but digital LOTO training integrates technical skills for managing automated energy control systems.

Cost Implications and Return on Investment

Manual Lockout-Tagout systems generally incur lower initial costs but involve higher labor expenses and increased risk of human error, potentially leading to costly downtime and safety incidents. Digital Lockout-Tagout solutions require a higher upfront investment for technology and training but offer significant savings through streamlined processes, enhanced compliance tracking, and reduced incident-related costs. Companies adopting digital systems often experience a stronger return on investment due to improved efficiency, minimized production stoppages, and better regulatory adherence.

Scalability and Integration with Industrial Systems

Digital Lockout-Tagout systems offer superior scalability compared to manual methods by enabling centralized control and real-time updates across multiple facilities. Integration with industrial IoT platforms and SCADA systems enhances monitoring capabilities and automates compliance reporting. Manual Lockout-Tagout lacks these integration features, limiting efficiency in large-scale operations and complex industrial environments.

Future Trends in Lockout-Tagout Safety

Future trends in lockout-tagout safety emphasize integrating digital lockout-tagout (LOTO) systems with Internet of Things (IoT) devices and cloud-based platforms to enhance real-time monitoring and data analytics. Automated digital LOTO solutions improve compliance tracking, streamline audit processes, and reduce human error compared to traditional manual lockout-tagout methods. Advancements in wearable technology and mobile apps further enable remote management and instant notifications, fostering safer work environments on industrial sites.

Related Important Terms

Digital LOTO Platforms

Digital Lockout-Tagout (LOTO) platforms enhance workplace safety by providing real-time equipment status updates, reducing human error, and ensuring compliance with OSHA regulations. These platforms integrate with existing safety systems, offering automated audit trails, remote access control, and instant communication to streamline lockout-tagout procedures.

Cloud-based Lockout Management

Cloud-based lockout management systems enhance safety by enabling real-time monitoring and centralized control of lockout-tagout procedures across multiple locations. These digital platforms reduce human error, streamline compliance reporting, and provide secure, accessible audit trails compared to traditional manual lockout-tagout methods.

IoT-enabled LOTO Devices

IoT-enabled digital Lockout-Tagout (LOTO) devices enhance safety by providing real-time monitoring, remote control, and automated alerts, significantly reducing human errors compared to traditional manual LOTO methods. These connected systems integrate with industrial networks to ensure compliance, streamline audit trails, and improve response times during equipment maintenance.

e-LOTO (Electronic Lockout-Tagout)

Electronic Lockout-Tagout (e-LOTO) systems streamline safety protocols by replacing traditional manual lockout-tagout methods with digital controls, enhancing compliance through real-time monitoring and audit trails. These digital solutions reduce human error, enable remote access management, and improve overall workplace safety by ensuring equipment is securely de-energized before maintenance.

Smart Lockout Verification

Smart Lockout Verification enhances traditional Manual Lockout-Tagout procedures by integrating real-time digital monitoring and authentication, significantly reducing human error and unauthorized equipment activation. Digital Lockout-Tagout systems provide comprehensive audit trails and instant status updates, improving workplace safety compliance and incident response efficiency.

Real-time LOTO Audit Trails

Digital Lockout-Tagout systems provide real-time LOTO audit trails, enabling instant tracking and verification of lockout status, which significantly enhances compliance monitoring and operational safety. Manual Lockout-Tagout relies on physical records prone to errors and delays, making real-time audit and incident response less efficient.

NFC-enabled Safety Tagging

NFC-enabled safety tagging in digital lockout-tagout systems enhances hazard communication by enabling instant, secure access to real-time lockout status and safety procedures via smartphones, significantly reducing human error compared to manual methods. This technology improves compliance, traceability, and workplace safety through precise electronic documentation and remote authorization, making digital lockout-tagout a superior choice for modern industrial environments.

LOTO Compliance Analytics

Digital Lockout-Tagout systems enhance LOTO compliance analytics by providing real-time data tracking, automated audit trails, and instant reporting, significantly reducing human error compared to traditional manual methods. These advanced analytics enable safety managers to identify non-compliance trends, streamline corrective actions, and ensure adherence to OSHA standards more effectively.

Mobile LOTO Workflows

Digital Lockout-Tagout (LOTO) systems streamline mobile LOTO workflows by enabling real-time updates, remote monitoring, and automated compliance tracking, reducing human error compared to traditional manual LOTO methods. Mobile LOTO apps improve safety by allowing workers to access and manage lockout procedures directly from devices on-site, enhancing efficiency and accountability in hazardous energy control.

Contactless LOTO Activation

Contactless LOTO activation via digital lockout-tagout systems enhances worker safety by eliminating physical contact with hazardous equipment, reducing contamination risks and operational downtime. Manual lockout-tagout relies on physical locks and tags, increasing exposure to hazards and human error, whereas digital solutions enable remote control and real-time monitoring for efficient and secure safety compliance.

Manual Lockout-Tagout vs Digital Lockout-Tagout Infographic

industrydif.com

industrydif.com