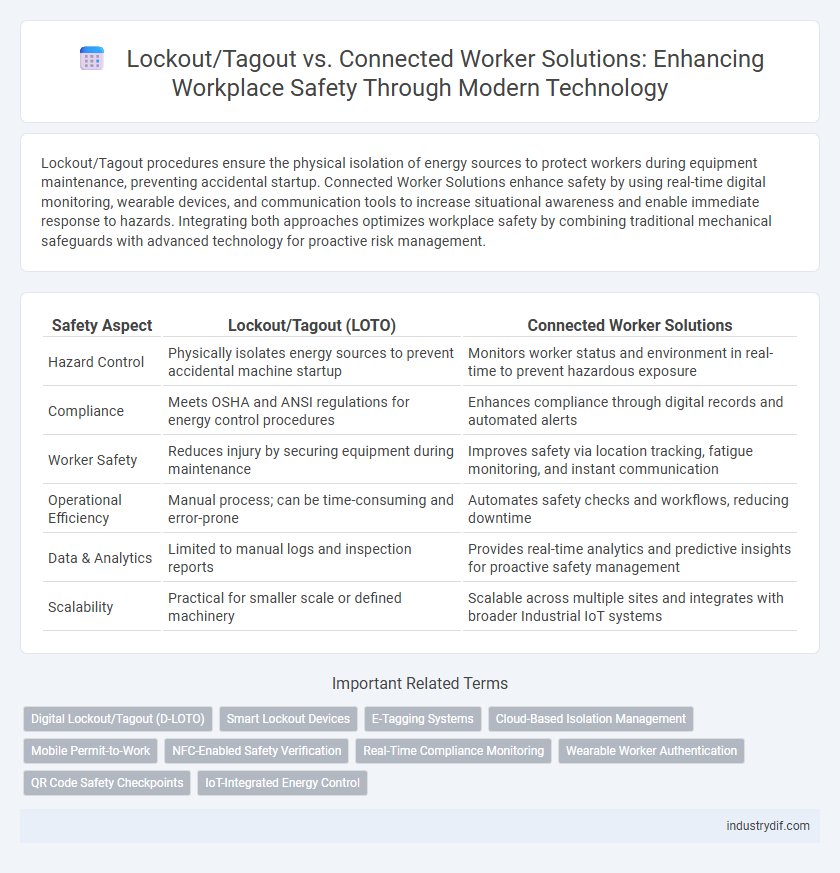

Lockout/Tagout procedures ensure the physical isolation of energy sources to protect workers during equipment maintenance, preventing accidental startup. Connected Worker Solutions enhance safety by using real-time digital monitoring, wearable devices, and communication tools to increase situational awareness and enable immediate response to hazards. Integrating both approaches optimizes workplace safety by combining traditional mechanical safeguards with advanced technology for proactive risk management.

Table of Comparison

| Safety Aspect | Lockout/Tagout (LOTO) | Connected Worker Solutions |

|---|---|---|

| Hazard Control | Physically isolates energy sources to prevent accidental machine startup | Monitors worker status and environment in real-time to prevent hazardous exposure |

| Compliance | Meets OSHA and ANSI regulations for energy control procedures | Enhances compliance through digital records and automated alerts |

| Worker Safety | Reduces injury by securing equipment during maintenance | Improves safety via location tracking, fatigue monitoring, and instant communication |

| Operational Efficiency | Manual process; can be time-consuming and error-prone | Automates safety checks and workflows, reducing downtime |

| Data & Analytics | Limited to manual logs and inspection reports | Provides real-time analytics and predictive insights for proactive safety management |

| Scalability | Practical for smaller scale or defined machinery | Scalable across multiple sites and integrates with broader Industrial IoT systems |

Introduction to Lockout/Tagout (LOTO) and Connected Worker Solutions

Lockout/Tagout (LOTO) is a critical safety procedure designed to prevent accidental machine energization during maintenance by isolating energy sources and applying lock devices. Connected Worker Solutions leverage IoT technology and wearable devices to enhance real-time communication, hazard identification, and compliance monitoring on industrial sites. Integrating LOTO protocols with Connected Worker platforms significantly improves safety outcomes by combining physical energy isolation with digital oversight and worker awareness.

Core Principles of Lockout/Tagout in Industrial Safety

Lockout/Tagout (LOTO) core principles in industrial safety center on isolating energy sources to prevent accidental machine startup during maintenance, using standardized lock and tag devices to ensure visibility and security. Effective LOTO procedures mandate employee training, verification of energy isolation, and consistent communication to minimize hazards and protect workers from electrical, mechanical, hydraulic, or pneumatic energy releases. These principles provide a foundational safety framework, contrasting with connected worker solutions that emphasize real-time monitoring and digital compliance management.

Evolution of Workplace Safety: From LOTO to Digital Solutions

Lockout/Tagout (LOTO) procedures have long been essential in preventing equipment-related accidents by physically isolating energy sources during maintenance. The evolution towards Connected Worker Solutions integrates digital technologies such as IoT sensors and real-time monitoring to enhance safety protocols, ensuring continuous hazard awareness and faster response times. This shift from manual to smart safety systems increases operational efficiency and significantly reduces human error in industrial environments.

Key Functions of Connected Worker Technology

Connected Worker solutions enhance safety by integrating real-time data, communication, and remote support, surpassing traditional Lockout/Tagout methods that primarily focus on physical isolation of hazardous energy. Key functions include continuous monitoring of worker location, automated hazard alerts, and digital verification of lockout/tagout procedures, reducing human error and increasing compliance. These technologies enable proactive risk management, improving overall workplace safety and operational efficiency.

Compliance and Regulatory Considerations: LOTO and Modern Safety Tools

Lockout/Tagout (LOTO) procedures remain essential for compliance with OSHA's control of hazardous energy standard (29 CFR 1910.147), ensuring that machinery is properly de-energized during maintenance. Connected Worker solutions enhance LOTO by integrating digital verification, real-time monitoring, and automated compliance reporting, reducing human error and improving audit readiness. Combining traditional LOTO practices with smart safety technologies supports meeting regulatory requirements while advancing workplace safety management.

Limitations of Traditional Lockout/Tagout Procedures

Traditional Lockout/Tagout (LOTO) procedures often face limitations such as reliance on manual processes that increase human error risks and prolonged downtime due to cumbersome equipment isolation steps. These procedures lack real-time monitoring and communication capabilities, hindering effective hazard recognition and response. Connected Worker Solutions address these gaps by enabling automated equipment status tracking, worker location awareness, and instant safety alerts, enhancing compliance and operational efficiency.

Enhancing Safety Protocols with Connected Worker Systems

Connected Worker Solutions enhance safety protocols by integrating real-time monitoring and automated lockout/tagout (LOTO) procedures, reducing human error and ensuring compliance. These systems leverage IoT sensors, wearable devices, and mobile applications to provide instant notifications and status updates on equipment lockout conditions. By enabling continuous communication and data-driven decision-making, Connected Worker Solutions significantly improve workplace safety and operational efficiency compared to traditional LOTO methods.

Integration Challenges: Bridging LOTO and Connected Worker Solutions

Integrating Lockout/Tagout (LOTO) procedures with Connected Worker Solutions requires overcoming challenges related to real-time data synchronization and ensuring secure access control across digital platforms. The convergence demands robust interoperability between traditional mechanical safety systems and IoT-enabled devices to maintain compliance with OSHA standards. Effective integration enhances worker safety by providing instant status updates and streamlined communication, reducing the risk of unauthorized equipment energization.

Case Studies: Success Stories in Safety Optimization

Case studies reveal Lockout/Tagout (LOTO) procedures significantly reduce workplace accidents by ensuring machinery is properly de-energized during maintenance, with organizations reporting up to a 40% decrease in lockout-related incidents. Connected Worker Solutions integrate real-time monitoring and wearable technology, enabling proactive hazard detection and immediate response, resulting in a 30% improvement in safety compliance and faster incident resolution. Combining LOTO protocols with connected worker tech has proven to optimize safety measures, enhance worker engagement, and minimize downtime in industrial environments.

Future Trends in Industrial Safety: Digital Vs. Manual Approaches

Lockout/Tagout procedures remain fundamental for machine safety, but Connected Worker solutions are rapidly transforming industrial safety by integrating digital monitoring and real-time hazard detection. Future trends emphasize wearable technology and IoT connectivity, enabling predictive maintenance and automated compliance reporting to reduce human error. This digital shift enhances operational efficiency while maintaining regulatory adherence and worker protection in increasingly complex industrial environments.

Related Important Terms

Digital Lockout/Tagout (D-LOTO)

Digital Lockout/Tagout (D-LOTO) enhances traditional Lockout/Tagout safety protocols by integrating real-time monitoring, automated notifications, and centralized control through connected worker solutions, reducing human error and improving compliance rates. D-LOTO systems leverage IoT devices and mobile applications to streamline hazard isolation and facilitate efficient communication across teams, significantly increasing workplace safety in industrial environments.

Smart Lockout Devices

Smart lockout devices enhance traditional Lockout/Tagout procedures by enabling real-time monitoring and remote control, significantly reducing the risk of accidental equipment energization. Integrated with Connected Worker solutions, these intelligent devices improve worker safety compliance and streamline hazard identification through automated alerts and data analytics.

E-Tagging Systems

E-Tagging systems enhance lockout/tagout procedures by providing real-time digital tracking of equipment status, reducing human error and improving compliance with safety regulations. Connected worker solutions integrate E-Tagging to enable seamless communication and instant updates, ensuring accurate lockout verification and faster incident response.

Cloud-Based Isolation Management

Cloud-based isolation management in Lockout/Tagout systems enhances safety by providing real-time access to equipment status, ensuring accurate isolation of energy sources and reducing human error. Connected worker solutions leverage IoT and mobile technology to enable seamless communication and compliance tracking, improving incident response and operational transparency.

Mobile Permit-to-Work

Mobile Permit-to-Work systems integrated within Connected Worker solutions enhance Lockout/Tagout safety by providing real-time, digital authorization and status updates that reduce human error and streamline compliance tracking. These systems offer instant access to permits, hazard information, and remote monitoring capabilities, significantly improving operational safety and reducing downtime compared to traditional Lockout/Tagout procedures.

NFC-Enabled Safety Verification

NFC-enabled safety verification in lockout/tagout systems enhances worker protection by ensuring real-time identification and authentication of authorized personnel during equipment maintenance. Connected worker solutions leverage NFC technology to provide seamless, digital confirmation of lockout status, reducing human error and improving compliance with safety protocols.

Real-Time Compliance Monitoring

Real-time compliance monitoring in Lockout/Tagout ensures immediate identification and mitigation of unauthorized energy source reactivations, minimizing workplace hazards. Connected Worker Solutions enhance this by integrating IoT devices and wearable technology, offering continuous visibility and automated alerts to maintain strict adherence to safety protocols.

Wearable Worker Authentication

Wearable worker authentication in connected worker solutions enhances Lockout/Tagout safety by providing real-time identity verification and ensuring only authorized personnel access hazardous equipment, reducing human error risks. This technology integrates biometric or RFID-based authentication to enforce compliance and improve incident tracking compared to traditional Lockout/Tagout procedures.

QR Code Safety Checkpoints

QR Code Safety Checkpoints enhance Lockout/Tagout procedures by providing real-time verification of equipment status and access permissions, reducing human error and ensuring compliance with safety protocols. Connected Worker Solutions integrate these checkpoints into digital workflows, enabling instant tracking, documentation, and employee accountability for improved hazard control and operational safety.

IoT-Integrated Energy Control

Lockout/Tagout procedures are essential for traditional energy isolation, but IoT-integrated Connected Worker Solutions offer real-time monitoring and remote control capabilities, enhancing compliance and reducing human error. These smart systems utilize sensors and wireless connectivity to provide continuous safety status updates, improving hazard detection and operational efficiency in industrial environments.

Lockout/Tagout vs Connected Worker Solutions Infographic

industrydif.com

industrydif.com