Manual lockout involves physically isolating energy sources using padlocks and tags to ensure equipment remains de-energized during maintenance, providing a straightforward and reliable safety measure. Digital lockout tagout systems utilize electronic devices and software to monitor and control equipment status remotely, enhancing efficiency and tracking compliance. Both methods aim to prevent accidental machine startup, but digital systems offer improved audit trails and real-time updates compared to traditional manual approaches.

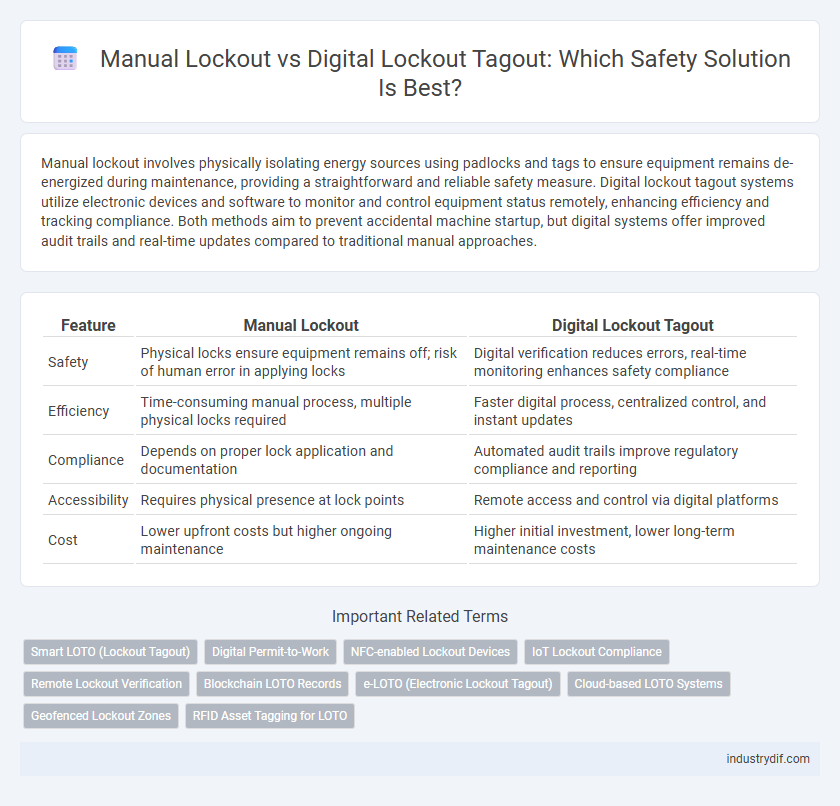

Table of Comparison

| Feature | Manual Lockout | Digital Lockout Tagout |

|---|---|---|

| Safety | Physical locks ensure equipment remains off; risk of human error in applying locks | Digital verification reduces errors, real-time monitoring enhances safety compliance |

| Efficiency | Time-consuming manual process, multiple physical locks required | Faster digital process, centralized control, and instant updates |

| Compliance | Depends on proper lock application and documentation | Automated audit trails improve regulatory compliance and reporting |

| Accessibility | Requires physical presence at lock points | Remote access and control via digital platforms |

| Cost | Lower upfront costs but higher ongoing maintenance | Higher initial investment, lower long-term maintenance costs |

Understanding Lockout Tagout: Manual vs Digital

Manual Lockout Tagout involves physically isolating energy sources using locks and tags to prevent accidental equipment startup, ensuring worker safety during maintenance. Digital Lockout Tagout systems leverage software and electronic devices to monitor and control energy isolation, providing real-time status updates and remote access for enhanced compliance and efficiency. Understanding the differences between manual and digital lockout tagout methods is crucial for implementing effective safety protocols tailored to specific industrial environments.

Key Differences Between Manual and Digital Lockout Tagout

Manual lockout tagout involves physical locks and tags to isolate hazardous energy, ensuring equipment cannot be operated during maintenance, while digital lockout tagout uses software systems to manage energy control procedures electronically, increasing efficiency and traceability. Manual methods rely on tactile verification and physical barriers, whereas digital systems provide real-time monitoring, audit trails, and remote authorization capabilities. The choice between manual and digital LOTO impacts compliance, safety risk reduction, and operational workflow integration in industrial environments.

Advantages of Manual Lockout Tagout Systems

Manual lockout tagout systems offer straightforward, cost-effective solutions for securing machinery during maintenance, ensuring clear physical isolation and preventing accidental startup. Their simplicity allows workers to quickly apply and verify locks without reliance on complex technology or battery power. Manual systems provide universal compatibility with various equipment types, enhancing workplace safety through direct, tangible control measures.

Benefits of Digital Lockout Tagout Solutions

Digital lockout tagout solutions enhance safety by providing real-time status updates and reducing human error through automated processes. These systems offer precise tracking and auditing capabilities, ensuring compliance with stringent safety regulations and minimizing downtime. Integration with mobile devices and cloud platforms enables seamless communication and faster incident response, improving overall workplace safety management.

Common Challenges in Manual Lockout Tagout Implementation

Manual Lockout Tagout (LOTO) faces common challenges such as human error, including improper lock placement and failure to verify energy isolation, which can lead to hazardous incidents. Inconsistent labeling and the physical limitations of manual locks increase the risk of unauthorized removal or equipment re-energization. The lack of real-time monitoring and audit trails in manual LOTO procedures complicates compliance tracking and accountability.

Enhancing Compliance with Digital Lockout Tagout

Digital Lockout Tagout systems enhance safety compliance by providing real-time status updates and automated audit trails, reducing human error and ensuring consistent lockout procedures. Unlike manual lockout methods, digital solutions offer centralized control and instant alerts, improving accountability and regulatory adherence. Integrating digital lockout tagout technology accelerates hazard identification and mitigates risks during maintenance.

Safety Impact: Comparing Manual and Digital Procedures

Manual Lockout procedures rely heavily on physical locks and tags to ensure machinery is safely de-energized, minimizing human errors through visible, tactile confirmation but are prone to inconsistencies and delays in documentation. Digital Lockout Tagout systems enhance safety impact by integrating real-time monitoring, automated alerts, and centralized record-keeping, significantly reducing lockout violations and improving compliance rates. Studies show facilities adopting digital lockout systems experience up to a 40% reduction in safety incidents related to improper lockout/tagout practices.

Integration of Digital Lockout Tagout in Industrial Settings

Digital Lockout Tagout systems enhance industrial safety by integrating automated controls with real-time monitoring, reducing human error inherent in manual procedures. These systems provide centralized management of lockout points, enabling faster compliance and streamlined audits through electronic documentation. Implementation of digital solutions minimizes downtime and increases worker safety by ensuring proper isolation of hazardous energy sources before maintenance activities.

Cost Considerations: Manual vs Digital Lockout Tagout

Manual lockout tagout systems typically involve lower initial costs due to basic equipment like padlocks, tags, and hasps, making them suitable for smaller budgets and simpler operations. Digital lockout tagout solutions require significant upfront investment in software, hardware, and training but offer long-term savings through improved compliance, real-time monitoring, and reduced downtime. Evaluating total cost of ownership, including maintenance and efficiency gains, is essential for choosing between manual and digital lockout tagout methods.

Future Trends in Lockout Tagout Technology

Emerging trends in lockout tagout technology prioritize digital systems integrating IoT sensors and real-time monitoring to enhance workplace safety and compliance. Manual lockout methods remain essential for their simplicity but are increasingly complemented by digital tools that provide automated audit trails and remote access controls. Future lockout tagout solutions emphasize predictive maintenance, data analytics, and seamless integration with smart factory environments to minimize human error and downtime.

Related Important Terms

Smart LOTO (Lockout Tagout)

Smart Lockout Tagout (LOTO) systems enhance workplace safety by integrating digital controls with traditional lockout procedures, enabling real-time monitoring and remote management of hazardous energy isolation. These advanced digital LOTO solutions reduce human error, improve compliance tracking, and accelerate lockout processes compared to manual lockout methods.

Digital Permit-to-Work

Digital Permit-to-Work systems enhance safety by providing real-time monitoring, automated workflows, and instant communication, reducing human error associated with Manual Lockout Tagout procedures. These digital solutions streamline compliance, enable detailed audit trails, and improve hazard identification for safer operational environments.

NFC-enabled Lockout Devices

NFC-enabled lockout devices enhance safety protocols by allowing quick, contactless verification and real-time status updates in lockout tagout procedures, reducing human error compared to traditional manual lockout methods. These digital systems integrate seamlessly with safety management software, providing detailed audit trails and facilitating compliance with OSHA and ANSI standards.

IoT Lockout Compliance

IoT lockout systems enhance compliance by providing real-time monitoring and automatic alerts, reducing human error common in manual lockout procedures. Digital lockout tagout solutions use interconnected sensors and cloud-based platforms to document and enforce safety protocols, increasing overall workplace safety and ensuring regulatory adherence.

Remote Lockout Verification

Manual lockout procedures rely on physical tags and locks to ensure equipment is de-energized, limiting verification to on-site inspections. Digital Lockout Tagout systems enhance safety with remote lockout verification through real-time status updates and audit trails, enabling faster response and reducing human error.

Blockchain LOTO Records

Digital Lockout Tagout (LOTO) systems enhanced with blockchain technology provide immutable, transparent records that significantly reduce human error and unauthorized access compared to manual lockout methods. Blockchain-enabled LOTO records ensure real-time verification, auditability, and higher compliance with safety regulations by securely logging every lockout event on a decentralized ledger.

e-LOTO (Electronic Lockout Tagout)

e-LOTO (Electronic Lockout Tagout) enhances workplace safety by providing real-time monitoring, automated audit trails, and remote lockout capabilities, reducing human error and improving compliance over traditional manual lockout systems. Integrating digital controls with sensor technology increases efficiency in hazardous energy isolation, ensuring faster response times and comprehensive lockout verification.

Cloud-based LOTO Systems

Cloud-based Lockout Tagout (LOTO) systems enhance workplace safety by enabling real-time monitoring, remote management, and centralized data access, significantly reducing human error compared to traditional manual lockout methods. These digital platforms streamline compliance tracking, improve audit readiness, and facilitate swift response to lockout status changes, bolstering overall operational safety and efficiency.

Geofenced Lockout Zones

Geofenced Lockout Zones in digital lockout tagout systems enhance safety by automatically restricting access to hazardous areas using GPS or RFID technology, reducing human error associated with manual lockout procedures. These zones provide real-time monitoring and alerts, ensuring compliance with safety protocols and significantly lowering the risk of unauthorized equipment activation.

RFID Asset Tagging for LOTO

RFID asset tagging enhances digital lockout tagout (LOTO) systems by providing precise, real-time tracking and verification of locked-out equipment, significantly reducing human error and unauthorized access during maintenance. Compared to manual lockout methods, RFID technology streamlines safety compliance, accelerates audits, and improves incident prevention through automated data logging and instant status updates.

Manual Lockout vs Digital Lockout Tagout Infographic

industrydif.com

industrydif.com