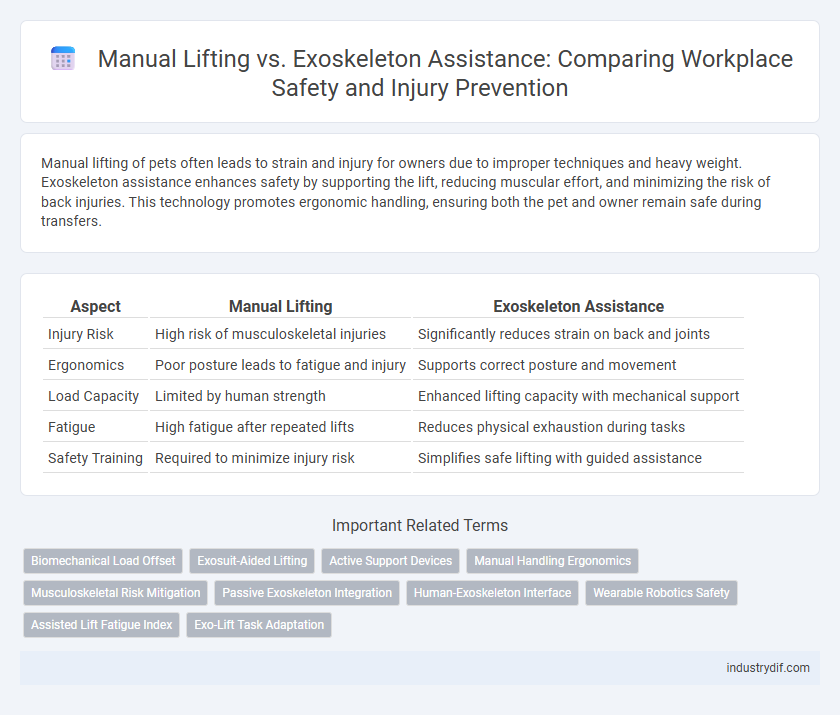

Manual lifting of pets often leads to strain and injury for owners due to improper techniques and heavy weight. Exoskeleton assistance enhances safety by supporting the lift, reducing muscular effort, and minimizing the risk of back injuries. This technology promotes ergonomic handling, ensuring both the pet and owner remain safe during transfers.

Table of Comparison

| Aspect | Manual Lifting | Exoskeleton Assistance |

|---|---|---|

| Injury Risk | High risk of musculoskeletal injuries | Significantly reduces strain on back and joints |

| Ergonomics | Poor posture leads to fatigue and injury | Supports correct posture and movement |

| Load Capacity | Limited by human strength | Enhanced lifting capacity with mechanical support |

| Fatigue | High fatigue after repeated lifts | Reduces physical exhaustion during tasks |

| Safety Training | Required to minimize injury risk | Simplifies safe lifting with guided assistance |

Introduction to Manual Lifting and Exoskeleton Assistance

Manual lifting remains a common method in workplaces, often leading to musculoskeletal disorders due to improper technique and heavy loads. Exoskeleton assistance offers enhanced support by redistributing weight and reducing strain on the back and joints, promoting safer lifting practices. Implementing exoskeletons can significantly decrease injury rates and improve overall worker safety in manual material handling tasks.

Common Hazards of Manual Lifting

Manual lifting frequently leads to musculoskeletal disorders, including strains and sprains, due to improper posture and excessive load weight. Workers are at risk of back injuries, herniated discs, and repetitive stress injuries when handling heavy or awkward objects without mechanical support. Ergonomic challenges such as uneven weight distribution and lack of sufficient rest periods exacerbate these hazards, increasing the likelihood of workplace accidents and long-term health issues.

Ergonomic Risks Associated with Traditional Lifting

Traditional manual lifting poses significant ergonomic risks, including musculoskeletal disorders caused by repetitive strain, poor posture, and heavy loads. These risks lead to increased incidences of lower back injuries, muscle fatigue, and joint stress among workers in industries like warehousing and construction. Exoskeleton assistance reduces these ergonomic hazards by improving posture, distributing weight more evenly, and decreasing physical exertion, thereby enhancing overall workplace safety.

How Exoskeletons Enhance Worker Safety

Exoskeletons significantly reduce the risk of musculoskeletal injuries by providing mechanical support and distributing weight more evenly during manual lifting tasks. These wearable devices enhance posture and decrease strain on the lower back and shoulders, which are common sites of injury in traditional manual lifting. By minimizing fatigue and improving ergonomic alignment, exoskeletons contribute to higher worker safety and productivity in physically demanding environments.

Comparing Injury Rates: Manual Lifting vs Exoskeleton Use

Manual lifting consistently exhibits higher injury rates, with musculoskeletal disorders accounting for approximately 33% of workplace injuries in industries reliant on this method. Exoskeleton assistance has demonstrated a reduction of injury incidence by up to 40%, significantly decreasing strain on the lower back and shoulders during repetitive lifting tasks. Emerging studies highlight the potential of exoskeleton technology to lower cumulative trauma disorders, promoting long-term workforce safety and reducing workers' compensation claims.

Regulatory Guidelines for Manual Lifting

Regulatory guidelines for manual lifting prioritize ergonomic assessments and adherence to weight limits set by organizations such as OSHA and NIOSH to minimize musculoskeletal disorders. Employers are required to implement training programs that emphasize proper lifting techniques and encourage the use of mechanical aids when lifting thresholds exceed recommended limits. Compliance with these standards reduces workplace injuries and supports employee safety in environments where manual handling is unavoidable.

Worker Training: Manual Methods vs Powered Assistance

Worker training for manual lifting emphasizes proper body mechanics, risk awareness, and injury prevention techniques to reduce musculoskeletal disorders. In contrast, training for exoskeleton-assisted lifting focuses on device operation, adjustment, and maintenance to maximize safety benefits and minimize malfunctions. Effective training programs combine ergonomic principles with hands-on exoskeleton use to enhance worker performance and reduce fatigue-related accidents.

Long-term Health Outcomes in Lifting Tasks

Manual lifting in occupational settings often results in musculoskeletal disorders due to repetitive strain and improper techniques, contributing to chronic back pain and long-term disability. Exoskeleton assistance reduces biomechanical load on the lower back and shoulders, promoting better posture and decreasing fatigue during prolonged lifting tasks. Studies indicate that integrating exoskeletons can significantly improve long-term health outcomes by minimizing injury rates and enhancing musculoskeletal health in manual labor environments.

Cost-Benefit Analysis: Manual vs Exoskeleton Investment

Manual lifting requires minimal upfront expenses but often leads to higher long-term costs from worker injuries and lost productivity. Exoskeleton assistance involves a significant initial investment in technology and training but can reduce injury rates and increase efficiency, lowering overall operational expenses. Conducting a cost-benefit analysis reveals that while manual lifting saves on immediate costs, exoskeletons offer better financial returns through improved workplace safety and reduced compensation claims.

Future Trends in Industrial Lifting Safety

Future trends in industrial lifting safety emphasize the integration of advanced exoskeleton technologies designed to reduce musculoskeletal injuries and enhance worker endurance. Data-driven ergonomic assessments combined with AI-powered exoskeletons optimize lifting postures and force distribution, minimizing fatigue and maximizing productivity. Continuous innovation in lightweight materials and sensor feedback systems will further improve the adaptability and safety of manual lifting tasks in industrial environments.

Related Important Terms

Biomechanical Load Offset

Manual lifting often results in high biomechanical load on the lower back, increasing the risk of musculoskeletal injuries, whereas exoskeleton assistance significantly reduces spinal compression forces by redistributing weight and supporting key muscle groups. Studies indicate that exoskeleton use can decrease lumbar load by up to 30-40%, enhancing worker safety and reducing fatigue during repetitive lifting tasks.

Exosuit-Aided Lifting

Exosuit-aided lifting significantly reduces musculoskeletal strain by supporting key muscle groups and promoting ergonomic postures, thereby decreasing workplace injury rates. Studies report up to a 40% reduction in lumbar load and enhanced lifting efficiency compared to traditional manual handling methods.

Active Support Devices

Active support devices in manual lifting, such as exoskeletons, significantly reduce musculoskeletal strain by providing targeted support to the lower back and shoulders, enhancing worker safety and endurance. These devices improve lifting ergonomics by distributing load forces more evenly, thereby minimizing the risk of workplace injuries and long-term physical damage.

Manual Handling Ergonomics

Manual lifting often leads to musculoskeletal disorders due to poor posture and repetitive strain, whereas exoskeleton assistance enhances manual handling ergonomics by reducing spinal load and supporting natural body mechanics. Improved ergonomic outcomes with exoskeletons contribute to lower injury rates and increased worker safety in physically demanding tasks.

Musculoskeletal Risk Mitigation

Manual lifting increases the risk of musculoskeletal disorders due to repetitive strain and heavy load on the lower back and shoulders, often resulting in long-term injuries. Exoskeleton assistance reduces biomechanical stress by supporting body posture and distributing weight more evenly, significantly lowering the incidence of musculoskeletal injuries in industrial settings.

Passive Exoskeleton Integration

Passive exoskeleton integration significantly reduces musculoskeletal strain by supporting the body's natural posture and distributing weight during manual lifting tasks, enhancing worker safety and decreasing injury rates. These devices operate without powered components, offering a low-maintenance, energy-efficient solution that improves endurance and reduces fatigue in repetitive lifting environments.

Human-Exoskeleton Interface

The human-exoskeleton interface enhances manual lifting safety by reducing musculoskeletal strain and improving load distribution through adaptive sensors and ergonomic design. Advanced feedback mechanisms enable real-time adjustments, minimizing the risk of injury compared to traditional manual lifting methods.

Wearable Robotics Safety

Wearable robotics like exoskeletons significantly reduce the risk of musculoskeletal injuries by supporting proper posture and distributing weight evenly during manual lifting tasks. These devices incorporate safety features such as real-time motion sensors and adaptive support, minimizing strain and preventing overexertion in industrial environments.

Assisted Lift Fatigue Index

The Assisted Lift Fatigue Index (ALFI) quantifies the reduction in muscle strain and endurance loss achieved through exoskeleton assistance during manual lifting tasks, demonstrating a significant decrease in fatigue-related injury risk. Studies reveal that workers using exoskeletons experience up to a 40% improvement in lift endurance, enhancing overall workplace safety by minimizing musculoskeletal disorders.

Exo-Lift Task Adaptation

Exo-Lift task adaptation enhances safety by reducing musculoskeletal strain and improving posture during manual lifting, leading to fewer workplace injuries. Integrating exoskeleton assistance with ergonomic task adjustments significantly lowers fatigue and increases lifting efficiency in industrial environments.

Manual Lifting vs Exoskeleton Assistance Infographic

industrydif.com

industrydif.com