Emergency Stop (E-Stop) devices are crucial for pet safety, providing an immediate way to halt machinery or equipment in hazardous situations. The E-Stop Mushroom button is a prominent type of emergency stop, designed with a large, easily recognizable mushroom-shaped head for quick activation during emergencies. This design enhances accessibility and ensures rapid response, minimizing risks and protecting pets from potential harm.

Table of Comparison

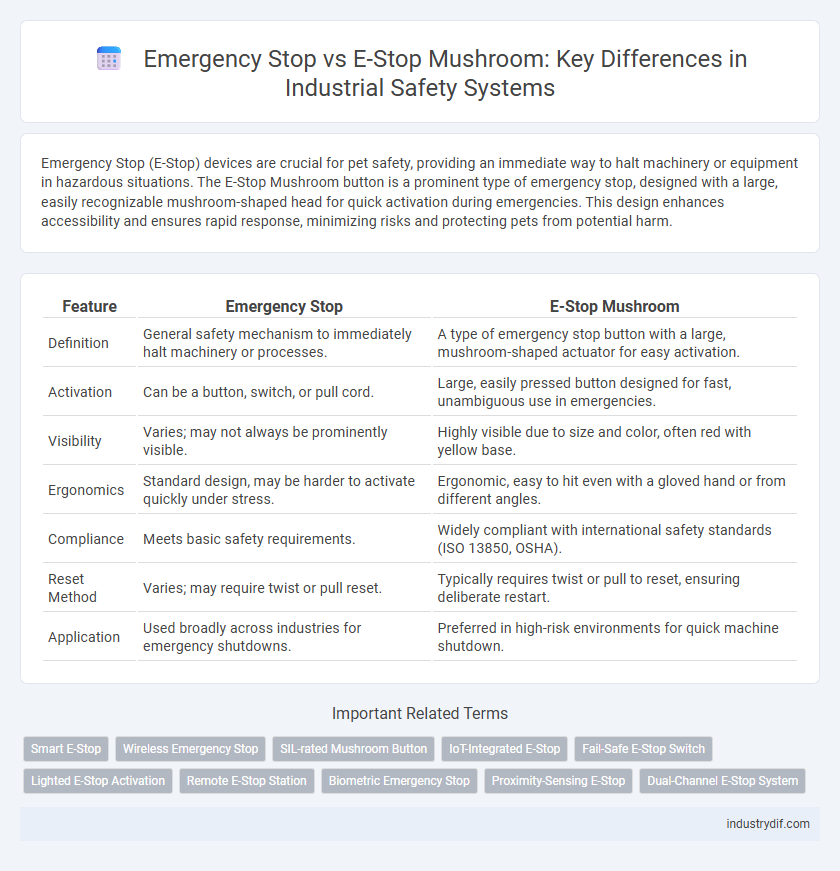

| Feature | Emergency Stop | E-Stop Mushroom |

|---|---|---|

| Definition | General safety mechanism to immediately halt machinery or processes. | A type of emergency stop button with a large, mushroom-shaped actuator for easy activation. |

| Activation | Can be a button, switch, or pull cord. | Large, easily pressed button designed for fast, unambiguous use in emergencies. |

| Visibility | Varies; may not always be prominently visible. | Highly visible due to size and color, often red with yellow base. |

| Ergonomics | Standard design, may be harder to activate quickly under stress. | Ergonomic, easy to hit even with a gloved hand or from different angles. |

| Compliance | Meets basic safety requirements. | Widely compliant with international safety standards (ISO 13850, OSHA). |

| Reset Method | Varies; may require twist or pull reset. | Typically requires twist or pull to reset, ensuring deliberate restart. |

| Application | Used broadly across industries for emergency shutdowns. | Preferred in high-risk environments for quick machine shutdown. |

Understanding Emergency Stop Systems in Industry

Emergency Stop (E-Stop) systems are critical safety mechanisms designed to immediately halt machinery operations to prevent accidents and injuries. E-Stop Mushroom buttons, characterized by their large, red, mushroom-shaped design, provide a highly visible and easily accessible interface for rapid activation in emergency situations. Understanding the implementation and maintenance of these systems ensures compliance with industrial safety standards like ISO 13850 and enhances workplace protection.

What is an E-Stop Mushroom Button?

An E-Stop Mushroom Button is a highly visible, large, red emergency stop switch designed for quick and easy activation to immediately halt machinery or equipment during hazardous situations. Its distinctive mushroom shape ensures rapid operation even under stress or with gloved hands, enhancing workplace safety and reducing accident risks. Often integrated into industrial control panels, E-Stop Mushroom Buttons comply with international safety standards such as ISO 13850, ensuring reliable emergency intervention.

Key Differences: Emergency Stop vs E-Stop Mushroom

Emergency Stop (E-Stop) buttons provide a crucial safety mechanism to immediately halt machinery or processes during emergencies, while the E-Stop Mushroom specifically refers to the visually distinctive, large, red, mushroom-shaped button designed for quick identification and easy activation. The key difference lies in the design and usability, as the Mushroom style enhances operator response time and accessibility, especially in high-risk environments. Both serve to interrupt power and stop operations, but the Mushroom type is often preferred for its ergonomic advantage and compliance with safety standards.

Industry Safety Standards for Emergency Stops

Emergency Stop (E-Stop) devices are critical for industrial safety, designed to quickly halt machinery to prevent accidents and injuries. E-Stop Mushroom buttons, characterized by their large, red, and easily identifiable design, comply with rigorous industry safety standards such as ISO 13850 and IEC 60947-5-5, ensuring rapid accessibility and reliability in emergency situations. Proper implementation and maintenance of E-Stop systems are essential for meeting regulatory requirements and minimizing workplace hazards.

Common Applications of Emergency Stop Devices

Emergency stop devices, including traditional E-Stop buttons and E-Stop mushroom switches, are commonly used in industrial machinery, conveyor systems, and automated production lines to instantly halt operations during hazardous situations. The mushroom-style E-Stop is favored for its large, easily accessible design, enabling quick activation in environments requiring rapid response and high visibility. Both devices comply with safety standards such as ISO 13850 and IEC 60947-5-5, ensuring reliable emergency shutdown functionality across various manufacturing and processing industries.

Design Requirements for E-Stop Mushrooms

E-Stop mushrooms must comply with ISO 13850 standards, featuring a large, red, and highly visible button designed for rapid activation in emergencies. The design requires a latching mechanism to maintain the stop condition until manually reset, ensuring machine safety and operator protection. Ergonomic considerations include a diameter typically ranging from 30 to 60 mm, enabling easy and intuitive engagement under stress.

Compliance and Regulatory Guidelines

Emergency Stop systems must comply with international standards such as ISO 13850 to ensure rapid machine shutdown during hazards, whereas E-Stop Mushroom buttons adhere to specific ergonomic and visibility requirements outlined in IEC 60947-5-5 for operator safety and ease of access. Regulatory guidelines mandate that E-Stop devices be prominently colored red with a yellow background for universal recognition and must be easily resettable only after hazard removal. Compliance with these standards is critical to minimize workplace accidents and meet OSHA and EU Machinery Directive safety requirements.

Best Practices for Emergency Stop Implementation

Emergency Stop implementation requires selecting reliable and easily accessible devices to ensure immediate machine shutdown during hazardous situations. E-Stop Mushroom buttons, characterized by their large, red, and mushroom-shaped design, are preferred for high visibility and rapid activation under stress. Best practices include regular functional testing, strategic placement for unobstructed access, and adherence to international safety standards such as ISO 13850 to maximize operator protection and minimize accident risks.

Maintenance and Testing of E-Stop Systems

Regular maintenance and testing of Emergency Stop (E-Stop) systems, especially mushroom-style push buttons, are crucial to ensure reliable performance during critical shutdowns. Periodic inspections should verify mechanical integrity, contact continuity, and proper button latching and reset functions to prevent failure in emergencies. Documentation of test results and adherence to industry standards such as IEC 60947-5-5 enhances safety compliance and system dependability.

Future Trends in Industrial Safety Interlocks

Future trends in industrial safety interlocks emphasize the integration of advanced sensors and smart E-Stop mushroom buttons with IoT connectivity to enhance real-time monitoring and rapid response. Emerging technologies enable predictive maintenance and automated shutdowns, reducing downtime and preventing hazardous incidents. The shift towards modular, wireless safety systems offers greater flexibility and scalability in emergency stop configurations, aligning with Industry 4.0 standards.

Related Important Terms

Smart E-Stop

Smart E-Stop systems enhance traditional Emergency Stop functions by integrating advanced sensors and IoT connectivity for real-time monitoring and predictive maintenance. Unlike standard Mushroom-style E-Stops, Smart E-Stops offer diagnostic feedback and remote reset capabilities, significantly improving workplace safety and minimizing downtime.

Wireless Emergency Stop

Wireless Emergency Stop systems enhance industrial safety by providing flexible, remote activation compared to traditional wired E-Stop Mushroom buttons, enabling rapid response in hazardous situations without physical proximity constraints. These wireless solutions leverage secure communication protocols and robust battery management to maintain reliability and compliance with safety standards such as ISO 13850 and IEC 60947-5-5.

SIL-rated Mushroom Button

SIL-rated Emergency Stop (E-Stop) mushroom buttons provide certified functional safety performance in industrial environments, ensuring rapid machine shutdown to prevent hazards. These devices comply with Safety Integrity Level (SIL) standards, delivering reliable operator protection and minimizing risk through robust design and stringent testing.

IoT-Integrated E-Stop

IoT-integrated E-Stops enhance industrial safety by enabling remote monitoring and real-time diagnostics, reducing downtime and ensuring rapid response during emergencies. Unlike traditional emergency stops, these smart devices communicate system status via IoT networks, facilitating predictive maintenance and seamless integration with safety management systems.

Fail-Safe E-Stop Switch

Fail-safe E-Stop switches, including Emergency Stop and E-Stop Mushroom buttons, are designed to immediately halt machinery to prevent accidents and ensure operator safety by cutting power or initiating a controlled shutdown. E-Stop Mushroom buttons provide enhanced visibility and ease of activation with their large, red, mushroom-shaped design, ensuring rapid response in emergency situations.

Lighted E-Stop Activation

Lighted E-Stop Activation enhances emergency stop functions by providing immediate visual feedback, improving operator response times and safety awareness in hazardous environments. The illuminated mushroom button design ensures clear, intuitive identification, reducing accidental resets and enhancing system reliability during critical shutdowns.

Remote E-Stop Station

Remote E-Stop Stations enhance safety by allowing emergency stop activation from a distance, ensuring rapid machine shutdown in hazardous situations without direct access to the control panel. These stations typically feature an E-Stop Mushroom button, designed for easy identification and operation, minimizing response time and reducing accident risk in industrial environments.

Biometric Emergency Stop

Biometric Emergency Stop systems enhance workplace safety by using fingerprint or retinal recognition to rapidly and securely halt machinery, reducing false activations common in traditional E-Stop Mushroom buttons. These advanced systems integrate with automated controls to ensure immediate shutdown while maintaining authorized operator access, crucial in high-risk industrial environments.

Proximity-Sensing E-Stop

Proximity-sensing E-Stops enhance safety by detecting operator presence without physical contact, reducing response time and preventing accidental activations compared to traditional emergency stop buttons. These advanced systems integrate with industrial machinery to provide immediate shutdown upon detecting hazards within a predefined proximity, significantly minimizing risk in high-speed or automated environments.

Dual-Channel E-Stop System

A Dual-Channel E-Stop system enhances safety by utilizing two independent circuits to ensure reliable emergency shutdown, reducing the risk of failure compared to single-channel Emergency Stop buttons. The E-Stop Mushroom design provides a large, easily accessible actuator that improves operator response time during critical situations, making it an essential component in high-risk industrial environments.

Emergency Stop vs E-Stop Mushroom Infographic

industrydif.com

industrydif.com