Near miss reporting relies on human observation and timely documentation to prevent potential accidents, often resulting in delayed responses and gaps in data accuracy. AI-driven safety monitoring continuously analyzes real-time data from sensors and cameras to detect hazards proactively, minimizing risks before incidents occur. Integrating AI technology enhances safety protocols by providing immediate alerts and comprehensive insights that traditional near miss reporting cannot achieve.

Table of Comparison

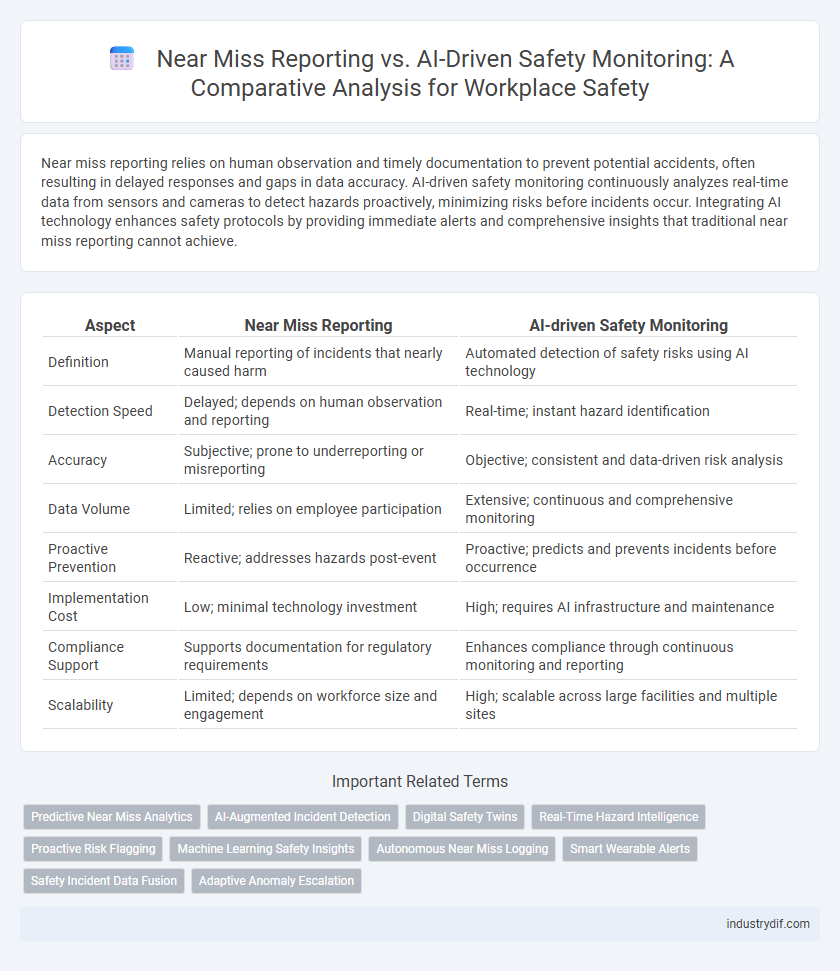

| Aspect | Near Miss Reporting | AI-driven Safety Monitoring |

|---|---|---|

| Definition | Manual reporting of incidents that nearly caused harm | Automated detection of safety risks using AI technology |

| Detection Speed | Delayed; depends on human observation and reporting | Real-time; instant hazard identification |

| Accuracy | Subjective; prone to underreporting or misreporting | Objective; consistent and data-driven risk analysis |

| Data Volume | Limited; relies on employee participation | Extensive; continuous and comprehensive monitoring |

| Proactive Prevention | Reactive; addresses hazards post-event | Proactive; predicts and prevents incidents before occurrence |

| Implementation Cost | Low; minimal technology investment | High; requires AI infrastructure and maintenance |

| Compliance Support | Supports documentation for regulatory requirements | Enhances compliance through continuous monitoring and reporting |

| Scalability | Limited; depends on workforce size and engagement | High; scalable across large facilities and multiple sites |

Understanding Near Miss Reporting in Industrial Safety

Near miss reporting in industrial safety involves documenting incidents that did not result in injury or damage but had the potential to do so, providing critical data for hazard identification and risk mitigation. Effective near miss reporting systems enable organizations to analyze patterns, prevent future accidents, and enhance workplace safety culture. Integrating near miss reports with AI-driven safety monitoring can improve real-time risk assessment by combining human-reported insights with predictive analytics.

The Role of AI-driven Monitoring in Modern Workplaces

AI-driven safety monitoring transforms modern workplaces by continuously analyzing real-time data to identify potential hazards before incidents occur. Unlike traditional near miss reporting, which relies on manual input and recall, AI systems use sensors, video analytics, and machine learning algorithms to detect patterns and predict risks with high accuracy. This proactive approach significantly reduces workplace accidents and enhances overall safety culture by enabling immediate interventions and informed decision-making.

Key Differences: Human Reporting vs. AI Detection

Near miss reporting relies on human observation and voluntary submission, which can result in underreporting due to fear or forgetfulness, whereas AI-driven safety monitoring continuously analyzes data from sensors and cameras to detect hazards in real-time. Human reporting provides detailed context and narrative insights that AI may miss, but AI systems offer scalability and consistency by identifying trends and patterns across vast data sets. Combining both approaches enhances workplace safety by leveraging human judgment alongside advanced machine learning algorithms for early hazard detection and prevention.

Data Accuracy and Efficiency: Manual vs. Machine

Near miss reporting relies heavily on manual input, often resulting in incomplete or delayed data that can hinder timely safety interventions. AI-driven safety monitoring leverages real-time data analytics and machine learning algorithms to enhance accuracy by automatically detecting potential hazards and anomalies. This technology improves efficiency by processing vast amounts of safety data instantly, reducing human error and enabling proactive risk management.

Real-time Response: Advantages of AI-driven Safety

AI-driven safety monitoring offers real-time response capabilities by continuously analyzing data from sensors and cameras, enabling immediate identification and mitigation of potential hazards. Unlike traditional near miss reporting, which relies on manual entry and retrospective analysis, AI systems provide proactive alerts that prevent accidents before they occur. This enhances overall workplace safety by reducing response times and minimizing human error in hazard detection.

Overcoming Human Bias in Near Miss Reporting

Near miss reporting often suffers from human bias, leading to underreporting or inconsistent data that hampers effective safety analysis. AI-driven safety monitoring leverages advanced algorithms and machine learning to detect patterns and anomalies objectively, minimizing subjective errors inherent in human reports. Integrating AI with near miss systems enhances accuracy in hazard identification, driving proactive safety interventions and reducing workplace incidents.

Integration Challenges: Merging Traditional and AI Systems

Integrating near miss reporting with AI-driven safety monitoring presents challenges such as data consistency, real-time processing, and interoperability between legacy systems and advanced analytics platforms. Traditional near miss reports often rely on manual input and subjective observations, whereas AI systems require structured data and continuous monitoring for predictive insights. Overcoming these integration hurdles demands standardized data frameworks and seamless communication protocols to maximize workplace safety outcomes.

Building a Proactive Safety Culture with AI

Near miss reporting provides valuable insights into potential hazards but relies heavily on manual submissions, leading to inconsistent data and delayed interventions. AI-driven safety monitoring continuously analyzes real-time environmental and behavioral data, identifying risks before incidents occur and enabling immediate corrective actions. Integrating AI enhances predictive safety measures, fostering a proactive culture that reduces accidents and improves overall workplace safety compliance.

Privacy and Ethical Considerations in AI Safety Monitoring

AI-driven safety monitoring enhances hazard detection by continuously analyzing workplace environments, but raises significant privacy concerns due to pervasive data collection and surveillance. Near miss reporting relies on voluntary employee input, preserving individual autonomy and reducing privacy risks, yet may suffer from underreporting and delayed responses. Ethical implementation of AI systems requires transparent data handling, strict access controls, and unbiased algorithms to balance safety improvements with respect for worker privacy rights.

Future Trends: The Evolution of Industrial Safety Practices

Near miss reporting remains a critical component in industrial safety, providing real-time data that helps identify potential hazards before accidents occur. AI-driven safety monitoring leverages machine learning algorithms and IoT sensors to analyze large datasets, predict risks, and automate hazard detection with greater accuracy. Future trends in industrial safety emphasize the integration of AI technologies with near miss reporting systems, enhancing predictive maintenance, reducing human error, and fostering proactive safety cultures.

Related Important Terms

Predictive Near Miss Analytics

Predictive Near Miss Analytics leverages AI-driven safety monitoring to identify potential hazards before incidents occur, enhancing workplace safety by analyzing patterns and trends from near miss reports. This proactive approach enables organizations to implement targeted interventions, reducing risks and preventing accidents more effectively than traditional near miss reporting alone.

AI-Augmented Incident Detection

AI-augmented incident detection enhances traditional near miss reporting by employing real-time data analysis and machine learning algorithms to identify potential hazards before they escalate into accidents. This technology increases workplace safety through continuous monitoring, predictive insights, and rapid response capabilities that significantly reduce human error and improve incident prevention.

Digital Safety Twins

Near miss reporting relies on manual inputs which often leads to underreporting, while AI-driven safety monitoring leverages Digital Safety Twins to simulate real-time operations and predict potential hazards with higher accuracy. Digital Safety Twins integrate sensor data and predictive analytics, enabling proactive risk management and reducing workplace accidents significantly.

Real-Time Hazard Intelligence

Near miss reporting relies on manual input and often delays hazard visibility, whereas AI-driven safety monitoring delivers real-time hazard intelligence by continuously analyzing data from sensors, cameras, and wearables to detect potential risks instantly. This proactive approach enhances workplace safety by enabling immediate intervention and reducing incident rates through predictive analytics and automated alerts.

Proactive Risk Flagging

Near Miss Reporting relies on human observation and timely documentation to identify potential hazards, often leading to delayed response times in risk mitigation. AI-driven Safety Monitoring utilizes real-time data analytics and machine learning algorithms to proactively flag emerging risks, enhancing early intervention and reducing workplace accidents.

Machine Learning Safety Insights

Near Miss Reporting relies on manual input and subjective observations, often leading to underreported incidents, while AI-driven Safety Monitoring utilizes machine learning algorithms to analyze vast data sets in real time, uncovering patterns and predicting potential hazards with greater accuracy. Machine learning safety insights enable proactive risk mitigation by continuously learning from near misses and incident data to enhance workplace safety outcomes and reduce accident rates.

Autonomous Near Miss Logging

Autonomous near miss logging leverages AI-driven safety monitoring systems to automatically detect, record, and analyze potential hazards without relying on manual reporting, significantly reducing underreporting issues in traditional near miss reporting methods. This technology enhances workplace safety by providing real-time insights and predictive analytics to prevent accidents before they occur.

Smart Wearable Alerts

Smart wearable alerts enhance AI-driven safety monitoring by providing real-time hazard detection and instant near miss reporting, reducing workplace accidents significantly. These devices leverage biometric data and environmental sensors to predict risks proactively, surpassing traditional near miss reporting methods in accuracy and response time.

Safety Incident Data Fusion

Near Miss Reporting captures real-time human observations of potential hazards, while AI-driven Safety Monitoring integrates diverse data sources such as sensor readings, video analytics, and historical incident records for comprehensive safety incident data fusion. Combining both approaches enhances predictive accuracy and proactive risk mitigation in workplace safety management.

Adaptive Anomaly Escalation

Adaptive Anomaly Escalation in AI-driven safety monitoring enhances near miss reporting by automatically identifying and prioritizing unusual patterns that human observers might overlook, enabling faster intervention. This technology leverages machine learning algorithms to dynamically assess risk levels and escalate potential hazards in real time, significantly improving workplace safety outcomes.

Near Miss Reporting vs AI-driven Safety Monitoring Infographic

industrydif.com

industrydif.com