Safety gloves provide essential protection against cuts, abrasions, and chemical exposure, making them ideal for general pet handling tasks. Exoskeleton gloves enhance strength and reduce fatigue by supporting hand movements, beneficial for intensive or repetitive activities in pet care. Choosing between the two depends on the level of protection needed and the physical demands of the task.

Table of Comparison

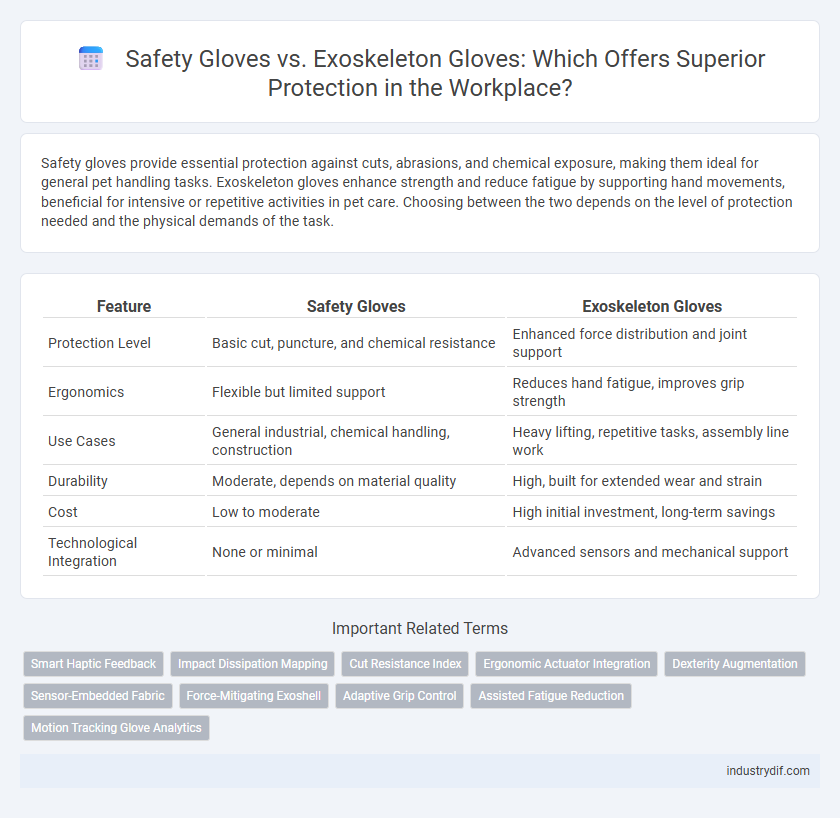

| Feature | Safety Gloves | Exoskeleton Gloves |

|---|---|---|

| Protection Level | Basic cut, puncture, and chemical resistance | Enhanced force distribution and joint support |

| Ergonomics | Flexible but limited support | Reduces hand fatigue, improves grip strength |

| Use Cases | General industrial, chemical handling, construction | Heavy lifting, repetitive tasks, assembly line work |

| Durability | Moderate, depends on material quality | High, built for extended wear and strain |

| Cost | Low to moderate | High initial investment, long-term savings |

| Technological Integration | None or minimal | Advanced sensors and mechanical support |

Overview of Safety Gloves and Exoskeleton Gloves

Safety gloves provide essential hand protection against hazards such as cuts, abrasions, chemical exposure, and impacts, making them crucial in industries like construction, manufacturing, and healthcare. Exoskeleton gloves enhance manual labor by incorporating mechanical support to reduce hand fatigue and increase lifting strength, ideal for repetitive or heavy-duty tasks. Both types improve workplace safety but serve distinct functions: safety gloves primarily shield the hand, while exoskeleton gloves augment physical capability.

Key Features and Functionalities

Safety gloves provide essential hand protection with materials like nitrile, leather, and Kevlar, offering cut resistance, chemical protection, and enhanced grip for various industrial tasks. Exoskeleton gloves integrate powered support systems to reduce hand fatigue, augment strength, and improve precision during repetitive or heavy-duty work. Combining traditional glove protection with ergonomic assistance, exoskeleton gloves enhance overall safety and productivity in demanding environments.

Material Composition and Durability

Safety gloves typically utilize high-strength materials such as Kevlar, nitrile, or leather, offering robust cut resistance and chemical protection tailored for specific industrial hazards. Exoskeleton gloves integrate advanced composites like carbon fiber and reinforced polymers within ergonomic frameworks that enhance durability while providing mechanical support to reduce user fatigue. The material composition of exoskeleton gloves emphasizes both protection and flexibility, extending glove lifespan under repetitive strain conditions compared to traditional safety gloves.

Protection Levels and Standards

Safety gloves provide essential protection against chemical, cut, and impact hazards, adhering to industry standards such as ANSI/ISEA 105 and EN 388 to ensure durability and resistance. Exoskeleton gloves enhance worker safety by reducing strain and fatigue while offering moderate protection, often integrating with standard safety gloves to meet protection requirements. Choosing between these gloves depends on assessing specific hazard exposure and compliance with safety certification levels to optimize hand protection and ergonomic support.

Ergonomics and User Comfort

Safety gloves provide essential hand protection with varied materials designed for flexibility and breathability, but they may cause hand fatigue during prolonged use. Exoskeleton gloves enhance ergonomics by incorporating mechanical support that reduces muscle strain and improves grip strength, promoting user comfort in extended tasks. Combining durability with ergonomic assistance, exoskeleton gloves offer superior comfort for workers requiring repetitive motions or heavy lifting.

Application Areas in Industrial Settings

Safety gloves provide essential protection against cuts, abrasions, and chemical exposures in industries such as manufacturing, construction, and warehousing. Exoskeleton gloves enhance worker endurance and reduce muscle fatigue in repetitive tasks, making them ideal for automotive assembly, heavy machinery operation, and logistics. Combining both technologies optimizes hand safety and efficiency in high-demand industrial environments.

Impact on Worker Productivity

Safety gloves provide essential hand protection but can sometimes reduce dexterity and increase fatigue, potentially limiting worker productivity during extended tasks. Exoskeleton gloves, designed with ergonomic support and powered assistance, enhance grip strength and reduce muscle strain, enabling workers to perform repetitive or heavy-duty tasks more efficiently. Studies indicate that exoskeleton gloves can improve productivity by up to 20% compared to conventional safety gloves due to decreased fatigue and increased endurance.

Cost Considerations and ROI

Safety gloves offer a low upfront cost and immediate protection for workers, making them a cost-effective choice for short-term use and routine tasks. Exoskeleton gloves involve a higher initial investment but provide long-term ROI through enhanced productivity, reduced worker fatigue, and decreased injury rates in physically demanding environments. Evaluating total cost of ownership, including maintenance and training, is crucial for selecting the optimal safety solution that balances budget constraints with operational efficiency.

Maintenance and Longevity

Safety gloves require regular inspection for tears and wear, with frequent replacement to maintain protective integrity, while exoskeleton gloves demand specialized maintenance due to their mechanical components, including battery checks and joint lubrication. The durability of safety gloves typically ranges from weeks to months depending on material and usage, whereas exoskeleton gloves offer extended longevity through robust construction and modular parts designed for easy repairs. Proper maintenance practices directly influence the lifespan and performance efficiency of both glove types, ensuring optimal safety standards in industrial environments.

Future Trends in Industrial Hand Protection

Emerging trends in industrial hand protection emphasize the integration of smart technologies in safety gloves to enhance user comfort and injury prevention. Exoskeleton gloves, equipped with powered assistive features, are revolutionizing dexterity support and reducing musculoskeletal strain during repetitive tasks. Future developments focus on combining advanced materials with AI-driven sensors to provide real-time feedback and adaptive protection tailored to specific workplace hazards.

Related Important Terms

Smart Haptic Feedback

Safety gloves with smart haptic feedback enhance user awareness by providing real-time touch and pressure signals, reducing injury risks during hazardous tasks. Exoskeleton gloves integrate advanced sensors and actuators to amplify hand strength and precision while delivering tactile feedback, improving safety and efficiency in industrial environments.

Impact Dissipation Mapping

Safety gloves provide basic impact dissipation by using foam or gel padding to absorb shocks, while exoskeleton gloves enhance impact dissipation through integrated rigid frames and sensor-driven actuation that redirect and mitigate forces away from vulnerable hand areas. Impact dissipation mapping in exoskeleton gloves leverages advanced materials and biomechanical analysis to optimize protective coverage and maximize force dispersion during hazardous tasks.

Cut Resistance Index

Safety gloves with a high Cut Resistance Index (CRI) offer essential hand protection against sharp objects, making them ideal for tasks involving glass, metal, or blades. Exoskeleton gloves enhance muscular endurance and reduce hand fatigue but generally provide lower cut resistance compared to specialized safety gloves designed to meet ANSI/ISEA or EN 388 standards.

Ergonomic Actuator Integration

Safety gloves with ergonomic actuator integration enhance hand protection by combining flexibility and resistance to impact, while exoskeleton gloves focus on augmenting grip strength and reducing muscle strain through powered actuators. Integrating ergonomic actuators in both glove types optimizes user comfort and efficiency, reducing workplace injuries related to repetitive motions and heavy lifting tasks.

Dexterity Augmentation

Safety gloves protect hands from hazards while offering limited dexterity, whereas exoskeleton gloves actively augment hand strength and precision through powered assistive technology, enabling enhanced manual performance in complex tasks. By integrating force sensors and actuators, exoskeleton gloves improve fine motor control and reduce fatigue, making them ideal for industrial applications requiring precise manipulation and extended wear.

Sensor-Embedded Fabric

Sensor-embedded fabric in safety gloves enhances real-time monitoring of hand movements and environmental hazards, providing improved protection and ergonomic support compared to traditional exoskeleton gloves. These smart textiles enable seamless integration of tactile feedback and motion sensors, optimizing grip strength and reducing the risk of repetitive strain injuries in industrial settings.

Force-Mitigating Exoshell

Force-mitigating exoshell gloves enhance safety by integrating rigid structures that redistribute and absorb impact forces, reducing strain and injury risk compared to traditional safety gloves. These exoskeleton gloves provide superior support for heavy-duty tasks, improving hand durability and worker endurance in hazardous environments.

Adaptive Grip Control

Safety gloves with adaptive grip control enhance manual dexterity and reduce hand fatigue by automatically adjusting pressure according to the object's shape and weight, improving worker efficiency and reducing the risk of grip-related injuries. Exoskeleton gloves integrate motorized assistance to amplify hand strength while maintaining adaptive grip control, offering superior ergonomic support in heavy-duty industrial applications.

Assisted Fatigue Reduction

Safety gloves designed for general protection reduce minor hand injuries while exoskeleton gloves actively assist in reducing muscle fatigue by providing powered support during repetitive or heavy tasks. Studies demonstrate exoskeleton gloves can decrease muscle strain by up to 30%, significantly enhancing worker endurance and reducing the risk of chronic musculoskeletal disorders.

Motion Tracking Glove Analytics

Safety gloves equipped with motion tracking glove analytics provide real-time data on hand movements and grip strength, enabling precise monitoring of worker ergonomics and reducing the risk of repetitive strain injuries. Exoskeleton gloves enhance this capability by integrating motion sensors with mechanical support, offering both injury prevention and augmented hand strength in industrial environments.

Safety Gloves vs Exoskeleton Gloves Infographic

industrydif.com

industrydif.com