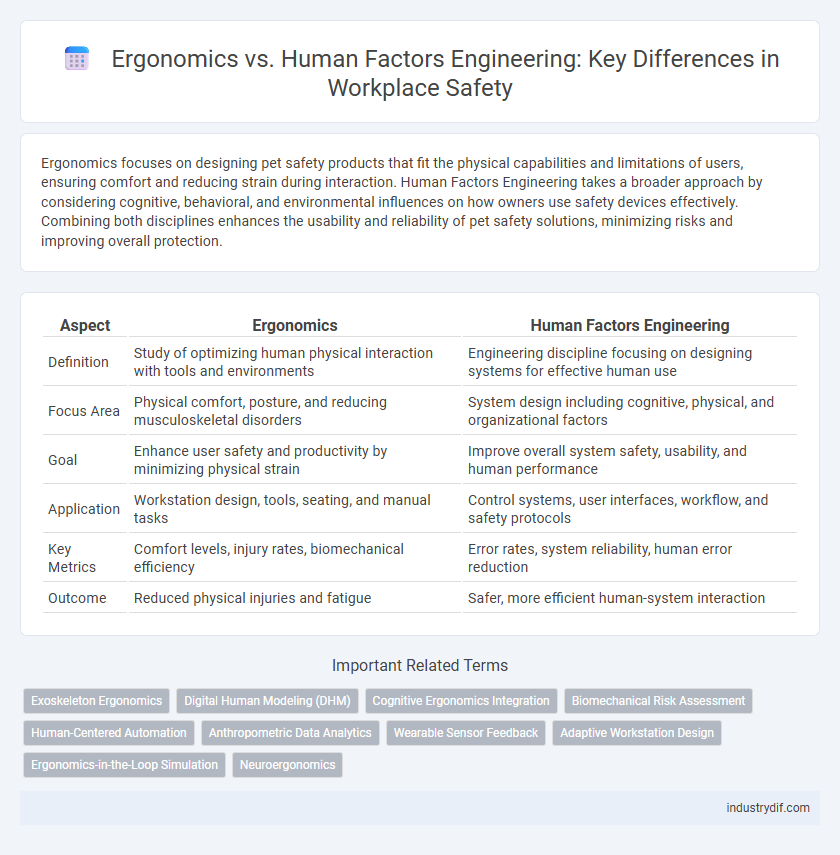

Ergonomics focuses on designing pet safety products that fit the physical capabilities and limitations of users, ensuring comfort and reducing strain during interaction. Human Factors Engineering takes a broader approach by considering cognitive, behavioral, and environmental influences on how owners use safety devices effectively. Combining both disciplines enhances the usability and reliability of pet safety solutions, minimizing risks and improving overall protection.

Table of Comparison

| Aspect | Ergonomics | Human Factors Engineering |

|---|---|---|

| Definition | Study of optimizing human physical interaction with tools and environments | Engineering discipline focusing on designing systems for effective human use |

| Focus Area | Physical comfort, posture, and reducing musculoskeletal disorders | System design including cognitive, physical, and organizational factors |

| Goal | Enhance user safety and productivity by minimizing physical strain | Improve overall system safety, usability, and human performance |

| Application | Workstation design, tools, seating, and manual tasks | Control systems, user interfaces, workflow, and safety protocols |

| Key Metrics | Comfort levels, injury rates, biomechanical efficiency | Error rates, system reliability, human error reduction |

| Outcome | Reduced physical injuries and fatigue | Safer, more efficient human-system interaction |

Introduction to Ergonomics and Human Factors Engineering

Ergonomics focuses on designing workplaces, tools, and tasks to fit the physical capabilities and limitations of humans, enhancing comfort, efficiency, and safety. Human Factors Engineering expands this scope by integrating psychological, cognitive, and organizational aspects to optimize overall system performance and reduce errors. Both disciplines aim to improve safety by minimizing human error and increasing user well-being in complex environments.

Defining Ergonomics in Industrial Safety

Ergonomics in industrial safety focuses on designing work environments and tasks to fit human capabilities and limitations, reducing the risk of injury and enhancing performance. Key elements include workstation layout, tool design, and repetitive motion analysis to prevent musculoskeletal disorders and improve comfort. Incorporating ergonomics principles leads to safer workplaces, decreased absenteeism, and higher productivity by minimizing human error and physical strain.

Understanding Human Factors Engineering

Human Factors Engineering focuses on designing systems and environments that match human capabilities and limitations to enhance safety and efficiency. It integrates knowledge from psychology, engineering, and physiology to optimize human interaction with tools, machines, and workspaces. Understanding Human Factors Engineering reduces errors, prevents accidents, and improves overall workplace safety by addressing cognitive, physical, and organizational factors.

Historical Evolution: Ergonomics vs Human Factors

Ergonomics originated in the early 20th century, emphasizing the design of tools and workspaces to fit human physical capabilities and limitations. Human Factors Engineering expanded in the mid-20th century, integrating psychological, cognitive, and organizational aspects to improve system performance and safety. The historical evolution reflects a shift from purely physical considerations in ergonomics to a multidisciplinary approach encompassing human behavior and system interactions in human factors.

Core Principles and Scope of Each Discipline

Ergonomics centers on designing tools and workspaces to fit human physical capabilities, emphasizing comfort, efficiency, and injury prevention through biomechanical analysis and anthropometric data. Human Factors Engineering encompasses a broader scope, integrating cognitive, physical, and organizational elements to optimize human-system interaction, focusing on task design, user interface, and error reduction. Core principles of Ergonomics include human-centered design and injury mitigation, while Human Factors Engineering prioritizes usability, system performance, and safety in complex environments.

Key Differences Between Ergonomics and Human Factors Engineering

Ergonomics primarily focuses on designing tools, equipment, and workspaces to fit human physical capabilities, aiming to reduce strain and enhance comfort. Human Factors Engineering encompasses a broader scope, including cognitive processes and organizational systems, optimizing overall human-system interaction to improve safety and efficiency. Key differences hinge on ergonomics addressing physical design elements while human factors engineering integrates psychological, environmental, and operational variables.

Overlapping Areas and Collaborative Approaches

Ergonomics and Human Factors Engineering both prioritize optimizing human performance and safety by addressing physical, cognitive, and environmental interactions in workplace design. Overlapping areas include task analysis, user-centered design, and risk assessment to reduce errors and enhance comfort. Collaborative approaches integrate multidisciplinary expertise to develop systems that improve safety outcomes and operational efficiency.

Impact on Workplace Safety and Productivity

Ergonomics enhances workplace safety and productivity by optimizing equipment and workspace design to fit human physical capabilities, reducing musculoskeletal disorders and fatigue. Human Factors Engineering broadens this scope by integrating cognitive and behavioral aspects, improving system interactions and minimizing human error in complex environments. Both disciplines contribute to safer, more efficient workplaces through tailored design and risk mitigation strategies.

Case Studies: Real-World Applications

Ergonomics focuses on designing workspaces to fit physical human needs, while Human Factors Engineering integrates cognitive and systemic considerations to optimize overall safety and performance. Case studies, such as reducing musculoskeletal injuries in assembly line workers and redesigning cockpit interfaces for pilots, demonstrate how these disciplines improve safety outcomes by addressing both physical and mental workload. Implementing ergonomic tools alongside comprehensive human factors assessments significantly decreases accident rates and enhances productivity in high-risk industries.

Choosing the Right Approach for Industrial Safety

Ergonomics centers on designing tools and workspaces to fit the physical needs of workers, reducing strain and injury risks. Human Factors Engineering expands this scope by integrating cognitive, organizational, and environmental aspects to optimize overall system performance and safety. Selecting the right approach for industrial safety depends on assessing specific workplace challenges, where ergonomics addresses physical interaction and human factors engineering ensures comprehensive risk mitigation through system design.

Related Important Terms

Exoskeleton Ergonomics

Exoskeleton ergonomics focuses on designing wearable robotic suits that enhance human physical capabilities while minimizing strain and injury risks, integrating anthropometric data to optimize fit and comfort. Human factors engineering expands this by systematically analyzing user interactions, cognitive load, and environmental conditions to ensure exoskeletons improve safety, efficiency, and user acceptance in workplace settings.

Digital Human Modeling (DHM)

Digital Human Modeling (DHM) integrates ergonomics and human factors engineering to optimize workplace design by simulating human interaction with digital environments, enhancing safety through improved task analysis and risk assessment. Utilizing advanced DHM software enables precise evaluation of human biomechanics and cognitive load, reducing injury risks and promoting efficient, user-centric system development.

Cognitive Ergonomics Integration

Cognitive ergonomics integration in safety design emphasizes optimizing mental processes such as perception, memory, and decision-making to reduce human error and enhance system performance. By combining human factors engineering with ergonomics, organizations create environments that support cognitive workload management, improving overall safety and operational efficiency.

Biomechanical Risk Assessment

Biomechanical risk assessment in ergonomics evaluates physical strain and musculoskeletal loading to prevent workplace injuries, emphasizing posture, force, and repetition metrics. Human Factors Engineering integrates these biomechanical insights with cognitive and environmental factors to design safer, more efficient systems that reduce overall human error and enhance safety outcomes.

Human-Centered Automation

Human-Centered Automation integrates principles of ergonomics and human factors engineering to design systems that optimize operator safety, reduce cognitive workload, and enhance decision-making accuracy. This approach prioritizes user interaction by tailoring automation to human capabilities and limitations, minimizing errors and improving overall system reliability in safety-critical environments.

Anthropometric Data Analytics

Ergonomics and Human Factors Engineering both utilize anthropometric data analytics to enhance workplace safety by optimizing design according to human body measurements and capabilities. Applying precise anthropometric datasets ensures equipment, tools, and environments reduce musculoskeletal disorders and improve overall user comfort and productivity.

Wearable Sensor Feedback

Wearable sensor feedback enhances ergonomics by providing real-time data on posture, movement, and muscle strain, enabling workers to adjust their positions to prevent musculoskeletal disorders. Human Factors Engineering integrates this sensor data into system design to optimize overall safety, performance, and user well-being in complex work environments.

Adaptive Workstation Design

Ergonomics emphasizes designing adaptive workstations that fit individual physical needs to reduce musculoskeletal disorders and enhance comfort. Human Factors Engineering integrates cognitive and physical considerations, optimizing workstation layouts to improve safety, efficiency, and user interaction within dynamic work environments.

Ergonomics-in-the-Loop Simulation

Ergonomics-in-the-loop simulation integrates human physical capabilities and limitations directly into system design processes, enhancing workplace safety by reducing musculoskeletal disorders and improving user comfort. This approach uses realistic, real-time interactions to optimize equipment interfaces, workflows, and environments based on ergonomic principles, surpassing traditional human factors engineering by embedding human biomechanical input throughout the simulation cycle.

Neuroergonomics

Neuroergonomics bridges ergonomics and human factors engineering by integrating neuroscience principles to optimize human-system interaction for enhanced safety and performance. This field focuses on understanding cognitive workload, attention, and brain function to design work environments that reduce errors and prevent accidents.

Ergonomics vs Human Factors Engineering Infographic

industrydif.com

industrydif.com