Workplace ergonomics reduces strain by optimizing tools and work environments to fit natural body movements, minimizing the risk of musculoskeletal injuries. Exoskeleton assistance enhances physical capabilities by providing external support that helps workers lift heavy loads and maintain proper posture for extended periods. Combining ergonomic design with exoskeleton technology offers a comprehensive approach to improving workplace safety and reducing fatigue.

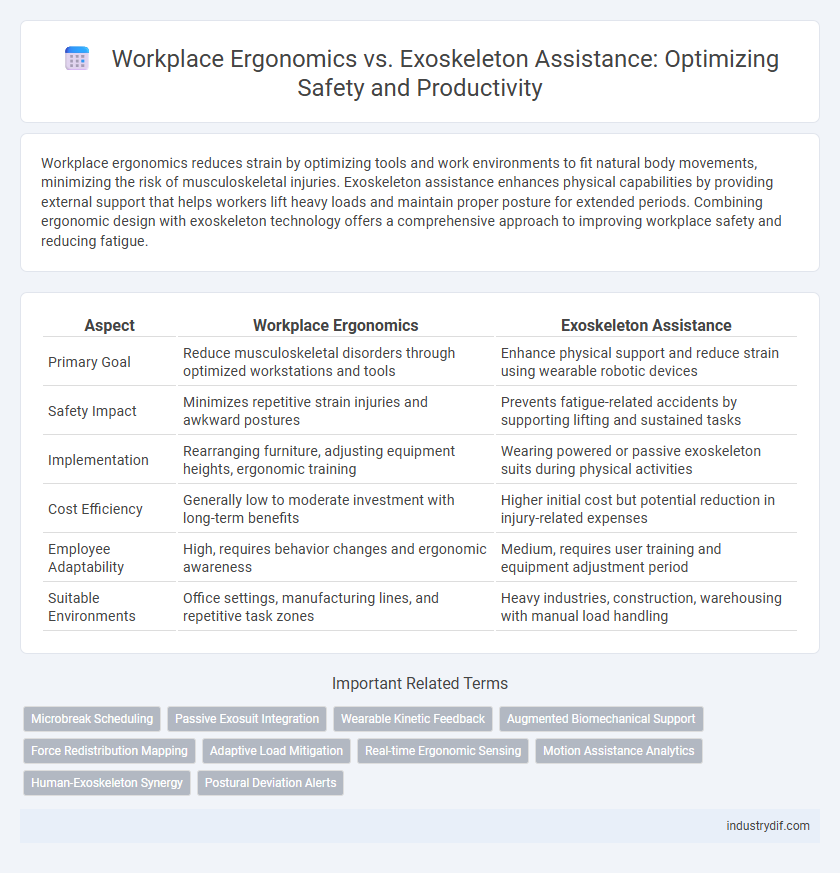

Table of Comparison

| Aspect | Workplace Ergonomics | Exoskeleton Assistance |

|---|---|---|

| Primary Goal | Reduce musculoskeletal disorders through optimized workstations and tools | Enhance physical support and reduce strain using wearable robotic devices |

| Safety Impact | Minimizes repetitive strain injuries and awkward postures | Prevents fatigue-related accidents by supporting lifting and sustained tasks |

| Implementation | Rearranging furniture, adjusting equipment heights, ergonomic training | Wearing powered or passive exoskeleton suits during physical activities |

| Cost Efficiency | Generally low to moderate investment with long-term benefits | Higher initial cost but potential reduction in injury-related expenses |

| Employee Adaptability | High, requires behavior changes and ergonomic awareness | Medium, requires user training and equipment adjustment period |

| Suitable Environments | Office settings, manufacturing lines, and repetitive task zones | Heavy industries, construction, warehousing with manual load handling |

Introduction to Workplace Ergonomics

Workplace ergonomics involves designing tasks, workstations, and tools to fit the worker's physical capabilities and limitations, reducing musculoskeletal disorders and enhancing productivity. Proper ergonomic practices focus on optimal posture, equipment positioning, and repetitive motion reduction to minimize injury risks. These principles serve as a foundation before integrating advanced solutions like exoskeleton assistance for improving worker safety and efficiency.

Defining Exoskeleton Assistance in Industry

Exoskeleton assistance in industry refers to wearable, powered devices designed to support and enhance workers' physical capabilities, reducing musculoskeletal strain and injury risks during repetitive or heavy tasks. Unlike traditional workplace ergonomics, which emphasize optimizing the physical environment and tools, exoskeletons provide direct biomechanical support to the user's body, improving posture and reducing fatigue. These advanced systems integrate sensors and actuators to adapt to movement, offering dynamic assistance that complements ergonomic practices for enhanced safety and productivity.

Key Differences Between Ergonomics and Exoskeleton Solutions

Workplace ergonomics focuses on designing tasks, workstations, and tools to fit the worker's physical needs, reducing strain and injury risks through proper posture and repetitive motion management. Exoskeleton assistance involves wearable robotic or mechanical devices that augment human strength and endurance, providing direct physical support to reduce muscle fatigue during heavy lifting or repetitive movements. Unlike ergonomic interventions that optimize existing workflows, exoskeletons actively enhance worker capabilities, making them complementary solutions in occupational safety strategies.

Impact on Worker Safety and Injury Prevention

Workplace ergonomics reduces musculoskeletal disorders by optimizing tools, tasks, and environments to fit workers' physical capabilities, significantly lowering injury risk. Exoskeleton assistance enhances worker safety by providing mechanical support and reducing strain during repetitive or heavy lifting tasks, preventing fatigue-related injuries. Combining ergonomic design with exoskeleton technology maximizes injury prevention and improves overall worker health and productivity.

Ergonomics Best Practices for Manual Labor

Workplace ergonomics best practices for manual labor emphasize proper body mechanics, workstation adjustments, and repetitive task management to reduce musculoskeletal injuries. Incorporating ergonomic tools such as adjustable lift tables and anti-fatigue mats further enhances worker comfort and productivity. Regular training on posture and safe lifting techniques ensures sustained injury prevention and workplace safety.

Exoskeleton Technologies: Types and Applications

Exoskeleton technologies encompass passive, active, and hybrid systems designed to enhance workplace ergonomics by reducing musculoskeletal strain and preventing injuries. Passive exoskeletons rely on mechanical supports without power sources to assist with load-bearing tasks, while active exoskeletons use motors and sensors to provide dynamic movement assistance tailored to specific job functions. Applications span industries such as manufacturing, construction, and healthcare, where exoskeletons improve worker safety, productivity, and long-term musculoskeletal health.

Cost-Benefit Analysis: Ergonomic Adjustments vs Exoskeleton Investment

Evaluating workplace ergonomics versus exoskeleton assistance requires a detailed cost-benefit analysis focusing on initial investment and long-term productivity gains. Ergonomic adjustments typically involve lower upfront costs through modifications such as adjustable furniture and ergonomic tools, reducing musculoskeletal disorders and associated absenteeism. In contrast, exoskeletons demand higher capital expenditure but may offer increased worker endurance and injury prevention, warranting consideration of maintenance, training, and scalability in budget planning.

Compliance with Occupational Health and Safety Standards

Workplace ergonomics and exoskeleton assistance both play crucial roles in ensuring compliance with occupational health and safety standards by reducing musculoskeletal disorders and workplace injuries. Ergonomic interventions align workstations and tasks with human capabilities, while exoskeletons provide physical support to workers performing repetitive or strenuous activities, enhancing safety and productivity. Integrating these solutions supports adherence to regulations such as OSHA's ergonomics guidelines and ISO 45001 standards, fostering safer work environments.

Human Factors: Adaptation and Acceptance in the Workplace

Workplace ergonomics aims to design tasks and environments that fit human capabilities, reducing strain and injury risks through proper posture and equipment adjustments. Exoskeleton assistance introduces mechanical support to augment human strength and endurance but requires careful consideration of user adaptation and acceptance to ensure effectiveness and comfort. Successful integration depends on addressing human factors such as ease of use, resistance to change, and training to foster long-term adoption and workplace safety improvements.

Future Trends: Integrating Ergonomics and Exoskeletons for Safer Workplaces

Future trends in workplace safety emphasize the integration of ergonomics with advanced exoskeleton technology to reduce musculoskeletal injuries and enhance worker productivity. Ergonomic designs combined with powered exoskeletons enable adaptive support tailored to individual tasks, improving posture and minimizing physical strain. Continuous innovation in sensor technology and AI-driven biomechanics promises smarter, responsive assistance systems that dynamically adjust to real-time workplace conditions.

Related Important Terms

Microbreak Scheduling

Workplace ergonomics emphasizes microbreak scheduling to reduce musculoskeletal strain by promoting frequent short rests, enhancing employee comfort and productivity. Exoskeleton assistance integrates microbreaks with mechanical support, further minimizing fatigue and injury risks through adaptive load distribution and movement reinforcement.

Passive Exosuit Integration

Passive exosuit integration in workplace ergonomics enhances worker safety by reducing musculoskeletal strain without the need for powered components, improving comfort and endurance during repetitive or strenuous tasks. Studies demonstrate that passive exosuits effectively lower injury rates and increase productivity by supporting natural movement and decreasing fatigue in industrial environments.

Wearable Kinetic Feedback

Wearable kinetic feedback in workplace ergonomics enhances employee safety by providing real-time motion analysis and posture correction, reducing strain and risk of musculoskeletal injuries. Integrating exoskeleton assistance with kinetic sensors improves task efficiency and supports natural movements, minimizing ergonomic hazards in industrial settings.

Augmented Biomechanical Support

Augmented biomechanical support through exoskeleton assistance enhances workplace ergonomics by reducing physical strain and preventing musculoskeletal disorders during repetitive or heavy lifting tasks. Integrating exoskeleton technology optimizes worker posture and movement efficiency, leading to increased safety and productivity in industrial environments.

Force Redistribution Mapping

Workplace ergonomics focuses on force redistribution mapping by analyzing human movement patterns to minimize musculoskeletal strain and optimize posture through adjustable workstations and ergonomic tools. Exoskeleton assistance enhances force redistribution by actively supporting joint loads and redistributing mechanical stresses away from vulnerable body areas, thereby reducing fatigue and the risk of injury during repetitive or heavy tasks.

Adaptive Load Mitigation

Workplace ergonomics aims to reduce musculoskeletal disorders through proper posture and tool design, while exoskeleton assistance provides adaptive load mitigation by dynamically supporting body movements and distributing weight to minimize strain. Integrating exoskeletons enhances ergonomic strategies by reducing fatigue and injury risk during repetitive or heavy-lifting tasks in industrial environments.

Real-time Ergonomic Sensing

Real-time ergonomic sensing enhances workplace safety by continuously monitoring workers' posture and movements to prevent musculoskeletal disorders. Integration with exoskeleton assistance systems offers dynamic support, reducing strain and improving ergonomic compliance through immediate feedback and adaptive adjustments.

Motion Assistance Analytics

Workplace ergonomics evaluates human movement to reduce strain and injury risks, while exoskeleton assistance leverages motion assistance analytics to enhance worker strength and endurance by analyzing joint angles, muscle activation, and lifting patterns in real-time. Integrating sensor data from wearable devices enables targeted interventions that improve posture, optimize load distribution, and minimize biomechanical stress during repetitive or heavy tasks.

Human-Exoskeleton Synergy

Workplace ergonomics enhances safety by optimizing human movement and reducing strain, while exoskeleton assistance supports musculoskeletal function to prevent injuries during repetitive or heavy tasks. The synergy between human biomechanics and exoskeleton technology maximizes efficiency and minimizes fatigue, leading to improved occupational health outcomes.

Postural Deviation Alerts

Workplace ergonomics leverages posture sensors to detect and alert employees of postural deviations, reducing the risk of musculoskeletal disorders by promoting neutral body alignment. Exoskeleton assistance enhances these alerts by providing real-time mechanical support and feedback, actively correcting posture and minimizing strain during repetitive or heavy tasks.

Workplace Ergonomics vs Exoskeleton Assistance Infographic

industrydif.com

industrydif.com