Polymer materials offer flexibility and tunable properties for scientific pet applications, enabling customized structural designs and biocompatibility. Metal-organic frameworks (MOFs) provide high surface area and porosity, facilitating enhanced gas storage and molecular sensing capabilities. Both polymers and MOFs contribute uniquely to advancing scientific pet technologies through their distinct mechanical and chemical characteristics.

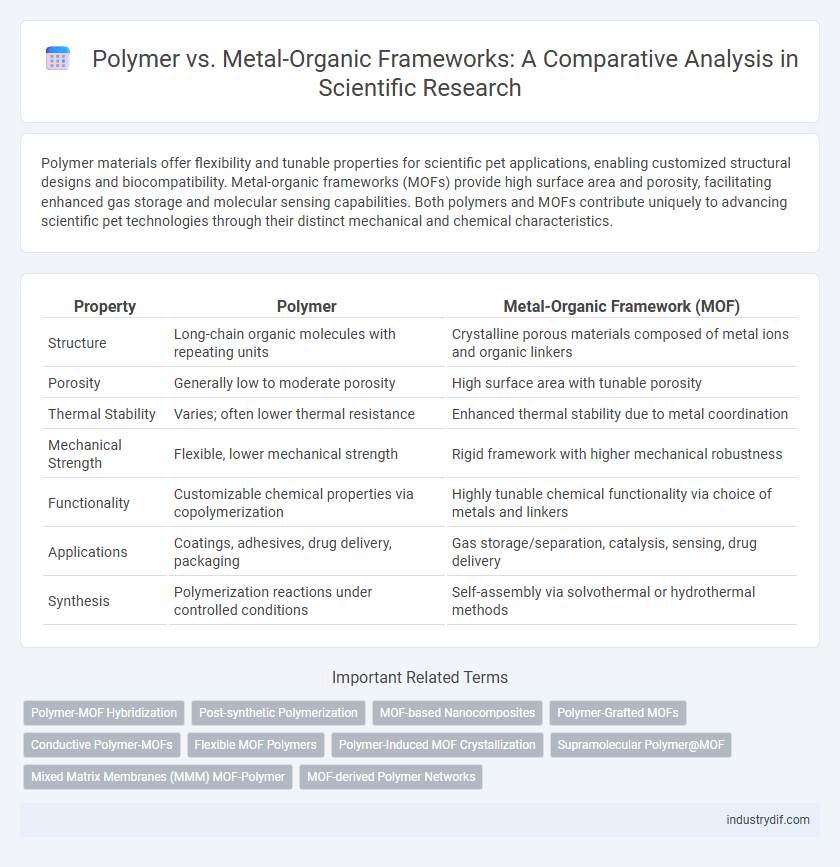

Table of Comparison

| Property | Polymer | Metal-Organic Framework (MOF) |

|---|---|---|

| Structure | Long-chain organic molecules with repeating units | Crystalline porous materials composed of metal ions and organic linkers |

| Porosity | Generally low to moderate porosity | High surface area with tunable porosity |

| Thermal Stability | Varies; often lower thermal resistance | Enhanced thermal stability due to metal coordination |

| Mechanical Strength | Flexible, lower mechanical strength | Rigid framework with higher mechanical robustness |

| Functionality | Customizable chemical properties via copolymerization | Highly tunable chemical functionality via choice of metals and linkers |

| Applications | Coatings, adhesives, drug delivery, packaging | Gas storage/separation, catalysis, sensing, drug delivery |

| Synthesis | Polymerization reactions under controlled conditions | Self-assembly via solvothermal or hydrothermal methods |

Introduction to Polymers and Metal-Organic Frameworks

Polymers are large macromolecules composed of repeating structural units called monomers, exhibiting diverse properties such as flexibility and chemical resistance critical for applications in materials science. Metal-Organic Frameworks (MOFs) are crystalline compounds consisting of metal ions coordinated to organic ligands, forming porous structures with high surface area useful for gas storage, catalysis, and sensing. Both polymers and MOFs represent advanced materials with tunable chemical and physical characteristics, enabling innovations in drug delivery, energy storage, and environmental remediation.

Structural Characteristics: Polymers vs MOFs

Polymers exhibit flexible, long-chain molecular structures with covalent bonds providing durability and adaptability in various applications, whereas Metal-Organic Frameworks (MOFs) feature crystalline, porous architectures formed by metal ions coordinated to organic ligands, resulting in high surface areas and tunable pore sizes. The amorphous or semi-crystalline nature of polymers contrasts with the well-defined, periodic lattices of MOFs, influencing their respective mechanical properties and functionalities. MOFs' structural rigidity and modularity enable precise control over gas storage and catalysis, while polymers offer versatility in processing and mechanical resilience.

Synthesis Methods of Polymers and MOFs

Synthesis of polymers typically involves chain-growth or step-growth polymerization techniques such as free-radical, anionic, cationic, or condensation polymerization, allowing precise control over molecular weight and polymer architecture. Metal-Organic Frameworks (MOFs) are synthesized through solvothermal or hydrothermal methods, utilizing metal ions and organic linkers to create highly porous crystalline structures with tunable pore sizes. Both synthesis approaches require careful optimization of reaction conditions like temperature, solvent, and reaction time to achieve desired structural and functional properties.

Thermal and Chemical Stability Comparison

Polymers generally exhibit moderate thermal stability with decomposition temperatures ranging from 200degC to 400degC, whereas Metal-Organic Frameworks (MOFs) display diverse thermal properties depending on their metal centers and organic linkers, often maintaining structural integrity up to 500degC or higher. Chemical stability in polymers is influenced by their backbone composition, with fluoropolymers demonstrating exceptional resistance to solvents and acids, while MOFs can vary greatly, where Zr-based MOFs show remarkable resistance to hydrolysis and harsh chemical environments compared to other MOF subclasses. This comparison highlights MOFs' tunable framework chemistry that allows enhanced thermal robustness and chemical resilience tailored for specific applications versus the more uniform but generally lower stability range of polymers.

Porosity and Surface Area Analysis

Polymer-based materials generally exhibit lower porosity and surface area compared to Metal-Organic Frameworks (MOFs), which feature highly tunable porous architectures and exceptionally large surface areas often exceeding 3000 m2/g. MOFs' crystalline structures enable precise control over pore size distribution, facilitating enhanced gas adsorption and molecular sieving applications. In contrast, polymers tend to have less uniform pore structures, limiting their efficacy in high-performance adsorption and catalysis processes.

Mechanical Properties: Strength and Flexibility

Polymer-based materials exhibit notable flexibility and moderate strength due to their long-chain molecular structures, making them ideal for applications requiring elasticity and impact resistance. Metal-Organic Frameworks (MOFs), composed of metal nodes interconnected by organic linkers, demonstrate exceptional strength arising from their crystalline lattice but typically lack the flexibility found in polymers. The mechanical properties of MOFs can be tuned by varying metal centers and organic linkers, potentially improving flexibility while maintaining high strength for advanced structural applications.

Functionalization and Tailoring Techniques

Polymer functionalization utilizes versatile chemical modifications such as grafting, copolymerization, and crosslinking to introduce specific functional groups, enhancing properties like selectivity and reactivity. Metal-Organic Frameworks (MOFs) leverage post-synthetic modification and linker exchange techniques to tailor pore environments and active sites, optimizing gas adsorption and catalytic performance. The precise control over functional group placement in MOFs contrasts with the broader tunability in polymers, making each material suitable for distinct applications in sensing, separation, and catalysis.

Applications in Gas Storage and Separation

Polymer materials exhibit tunable porosity and chemical stability, making them effective for gas storage and selective gas separation applications such as CO2 capture and natural gas purification. Metal-Organic Frameworks (MOFs) provide exceptionally high surface areas and adjustable pore sizes, enhancing gas adsorption capacity and separation efficiency for gases like hydrogen, methane, and carbon dioxide. Both polymers and MOFs play critical roles in advancing storage density and selectivity in industrial gas separation technologies.

Environmental Impact and Sustainability

Polymers often exhibit lower environmental impact than metal-organic frameworks (MOFs) due to their typically simpler synthesis and greater potential for biodegradability. MOFs, while highly effective for gas storage and catalysis, frequently rely on rare metals and complex ligands that pose challenges for large-scale sustainability and recycling. Advancements in green synthesis methods and renewable feedstocks are critical to reducing the ecological footprint of both polymers and MOFs in scientific and industrial applications.

Future Trends in Polymer and MOF Research

Future trends in polymer and metal-organic framework (MOF) research emphasize the development of hybrid materials combining the flexibility of polymers with the high surface area and tunable porosity of MOFs for advanced applications in gas storage, catalysis, and drug delivery. Innovations in controlled polymerization techniques and MOF synthesis enable precise structural design at the molecular level, enhancing performance and functionality in environmental and energy-related technologies. Emerging research prioritizes scalable production methods and the integration of computational modeling to accelerate material discovery and optimize real-world applicability.

Related Important Terms

Polymer-MOF Hybridization

Polymer-metal-organic framework (Polymer-MOF) hybridization combines the mechanical flexibility and processability of polymers with the high porosity and tunable functionality of MOFs, leading to enhanced gas storage, selective separation, and catalytic performance. This synergistic integration improves structural stability and facilitates the design of advanced materials for sensing, drug delivery, and environmental applications through adjustable chemical interactions and optimized surface properties.

Post-synthetic Polymerization

Post-synthetic polymerization (PSP) enhances Metal-Organic Frameworks (MOFs) by covalently linking polymer chains within their porous structures, significantly improving mechanical stability and functional versatility compared to traditional polymers. This approach allows for precise tuning of MOF properties such as gas adsorption capacity, catalytic activity, and chemical resistance, optimizing performance for advanced applications in separation, sensing, and catalysis.

MOF-based Nanocomposites

Metal-Organic Framework (MOF)-based nanocomposites exhibit superior surface area, tunable porosity, and enhanced chemical functionality compared to traditional polymers, making them highly effective for gas storage, catalysis, and drug delivery applications. Integrating MOFs with polymers improves mechanical stability and processability while preserving the unique adsorption and separation properties intrinsic to MOFs.

Polymer-Grafted MOFs

Polymer-grafted metal-organic frameworks (MOFs) exhibit enhanced stability and tunable surface properties compared to conventional MOFs, enabling improved performance in gas separation, catalysis, and drug delivery applications. The covalent bonding of polymers onto MOF surfaces facilitates selective permeability and mechanical robustness, combining the structural advantages of MOFs with the functional versatility of polymers.

Conductive Polymer-MOFs

Conductive Polymer-Metal Organic Frameworks (MOFs) combine the electrical conductivity of polymers with the high surface area and tunable porosity of MOFs, enabling enhanced electrochemical performance in sensors, energy storage, and catalysis applications. These hybrid materials exhibit synergistic properties such as improved charge transport, mechanical flexibility, and chemical stability, surpassing conventional pure polymer or MOF systems in conductivity and functional versatility.

Flexible MOF Polymers

Flexible metal-organic framework (MOF) polymers exhibit tunable porosity and structural adaptability, surpassing traditional polymers in gas storage and selective adsorption applications. Their hybrid organic-inorganic composition enhances mechanical flexibility and chemical stability, enabling responsive behavior under external stimuli such as pressure or temperature changes.

Polymer-Induced MOF Crystallization

Polymer-induced MOF crystallization enhances the nucleation and growth kinetics of metal-organic frameworks by providing tailored polymeric templates that influence crystal morphology and size distribution. This method significantly improves the structural tunability and functional properties of MOFs compared to conventional approaches, enabling applications in gas storage, catalysis, and sensing.

Supramolecular Polymer@MOF

Supramolecular Polymer@Metal-Organic Framework (MOF) composites combine the dynamic, reversible bonding of supramolecular polymers with the high surface area and tunable porosity of MOFs, enabling advanced functionalities such as selective gas adsorption and catalytic activity. This hybrid integration enhances mechanical stability and responsiveness, positioning Supramolecular Polymer@MOF materials as promising candidates for applications in sensing, drug delivery, and environmental remediation.

Mixed Matrix Membranes (MMM) MOF-Polymer

Mixed Matrix Membranes (MMM) combine the processability and mechanical strength of polymers with the high surface area and selective adsorption properties of Metal-Organic Frameworks (MOFs), enhancing gas separation performance. Integration of MOFs into polymer matrices improves permeability and selectivity by creating molecular sieving paths, crucial for applications in carbon capture and hydrogen purification.

MOF-derived Polymer Networks

MOF-derived polymer networks integrate the high surface area and tunable porosity of metal-organic frameworks (MOFs) with the flexibility and processability of polymers, resulting in enhanced gas adsorption and catalytic properties. These hybrid materials exhibit superior thermal stability and structural robustness compared to conventional polymers, making them ideal for applications in energy storage and environmental remediation.

Polymer vs Metal-Organic Framework Infographic

industrydif.com

industrydif.com