Logistics traditionally relies on trucks, ships, and trains to move goods through established networks, emphasizing cost-efficiency and accessibility. Hyperloop logistics introduces ultra-high-speed capsules traveling through near-vacuum tubes, drastically reducing transit times and enhancing supply chain responsiveness. This emerging technology promises to transform freight transport by minimizing delays and optimizing delivery routes.

Table of Comparison

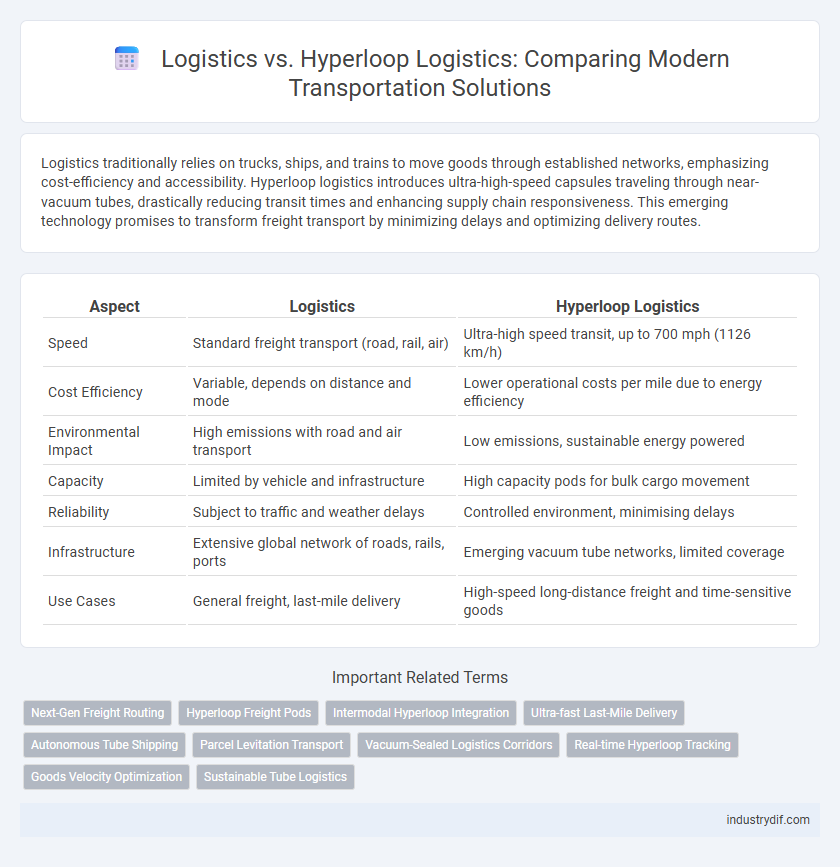

| Aspect | Logistics | Hyperloop Logistics |

|---|---|---|

| Speed | Standard freight transport (road, rail, air) | Ultra-high speed transit, up to 700 mph (1126 km/h) |

| Cost Efficiency | Variable, depends on distance and mode | Lower operational costs per mile due to energy efficiency |

| Environmental Impact | High emissions with road and air transport | Low emissions, sustainable energy powered |

| Capacity | Limited by vehicle and infrastructure | High capacity pods for bulk cargo movement |

| Reliability | Subject to traffic and weather delays | Controlled environment, minimising delays |

| Infrastructure | Extensive global network of roads, rails, ports | Emerging vacuum tube networks, limited coverage |

| Use Cases | General freight, last-mile delivery | High-speed long-distance freight and time-sensitive goods |

Introduction to Logistics and Hyperloop Logistics

Logistics involves the planning, implementation, and management of the efficient movement and storage of goods from origin to destination using traditional transport modes such as trucks, ships, and airplanes. Hyperloop logistics represents a cutting-edge advancement in transportation by leveraging near-vacuum tubes and magnetic levitation to enable ultra-fast, energy-efficient cargo delivery across long distances. This innovative technology aims to reduce transit times and operational costs significantly compared to conventional logistics systems, transforming supply chain dynamics worldwide.

Evolution of Traditional Logistics

Traditional logistics relies on ground vehicles like trucks and railways for freight transport, often facing challenges such as traffic congestion and slower delivery times. Hyperloop logistics introduces ultra-high-speed pods traveling through low-pressure tubes, drastically reducing transit times and increasing efficiency. This evolution transforms supply chain dynamics, enabling faster inventory turnover and enhanced reliability in time-sensitive shipments.

What Is Hyperloop Logistics?

Hyperloop logistics refers to the use of high-speed transportation systems that leverage magnetic levitation and low-pressure tubes to move goods rapidly and efficiently across long distances. This innovative mode of logistics offers significant advantages over traditional methods by drastically reducing transit times and operational costs, while improving energy efficiency and environmental sustainability. Incorporating hyperloop technology into logistics networks has the potential to revolutionize supply chain dynamics, enabling faster delivery, enhanced reliability, and optimized freight handling.

Key Differences Between Traditional and Hyperloop Logistics

Traditional logistics relies heavily on road, rail, and air transport, facing limitations such as traffic congestion, longer transit times, and higher carbon emissions. Hyperloop logistics offers ultra-high-speed cargo transport through low-pressure tubes, drastically reducing travel time and energy consumption while increasing reliability and scalability. Key differences include the mode of transport, speed capabilities, environmental impact, and infrastructure requirements, positioning hyperloop logistics as a transformative solution for future supply chain efficiency.

Speed and Efficiency Comparison

Hyperloop logistics dramatically reduces transit times by traveling at speeds up to 700 mph, compared to traditional logistics transportation averaging 50-60 mph via trucks or trains. This high-speed system enhances efficiency by minimizing delivery windows, reducing inventory holding costs, and improving supply chain responsiveness. Traditional logistics rely on existing infrastructure and are prone to delays from traffic and weather, whereas hyperloop's controlled environment ensures consistent, high-speed freight movement.

Cost Analysis: Conventional vs Hyperloop Logistics

Conventional logistics rely heavily on road, rail, and air transport, incurring substantial fuel, labor, and maintenance costs that cumulatively increase operational expenses. Hyperloop logistics, leveraging near-vacuum tube technology, offers significantly lower energy consumption and faster transit times, reducing both fuel costs and labor hours while enhancing supply chain efficiency. Cost analysis reveals hyperloop's potential to decrease overall logistics expenses by up to 30-50% compared to traditional methods, driven by reduced transit delays and minimized transportation overhead.

Environmental Impact and Sustainability

Hyperloop logistics significantly reduces carbon emissions compared to traditional logistics by utilizing magnetic levitation and electric propulsion, resulting in energy-efficient transport with minimal environmental footprint. Conventional logistics rely heavily on fossil fuels, contributing to air pollution and greenhouse gas emissions, which exacerbate climate change. Implementing hyperloop systems advances sustainability goals through lower energy consumption and decreased dependence on road and air freight, promoting greener supply chain operations.

Infrastructure Requirements and Challenges

Logistics infrastructure relies heavily on established road networks, warehouses, and distribution centers, requiring extensive land use and substantial investment in maintenance and expansion. Hyperloop logistics demands cutting-edge vacuum tube systems, magnetic levitation tracks, and energy-efficient stations, presenting significant engineering challenges and high initial capital costs. The integration of Hyperloop infrastructure with existing supply chains faces obstacles such as land acquisition, regulatory approvals, and technology standardization across regions.

Future Trends in Transportation Logistics

Hyperloop logistics promises ultra-fast, energy-efficient cargo transport by leveraging magnetic levitation and vacuum tubes, drastically reducing transit times compared to traditional logistics methods. Future trends indicate a shift toward integrating hyperloop networks with existing supply chains, enhancing real-time tracking, and minimizing carbon emissions. Advanced automation and AI-driven route optimization will further revolutionize transportation logistics by improving efficiency and reliability on a global scale.

Choosing the Right Logistics Solution for Your Business

Logistics solutions vary significantly in speed, cost, and environmental impact, making it essential to evaluate specific business needs when choosing the right option. Traditional logistics offers proven reliability and wide infrastructure support, while hyperloop logistics promises ultra-fast transit times and reduced carbon emissions through innovative vacuum tube technology. Assessing factors such as delivery deadlines, cargo type, and sustainability goals ensures the selection of a logistics solution that optimizes efficiency and competitiveness.

Related Important Terms

Next-Gen Freight Routing

Hyperloop logistics revolutionizes next-gen freight routing by enabling ultra-fast, energy-efficient transport through low-pressure tubes, drastically reducing transit times compared to traditional logistics relying on trucks and rail. Integrating advanced tracking systems and AI-driven route optimization, hyperloop logistics enhances supply chain reliability and sustainability in global freight management.

Hyperloop Freight Pods

Hyperloop Freight Pods revolutionize cargo transport by enabling ultra-fast, energy-efficient delivery with speeds exceeding traditional logistics methods, reducing transit times from days to hours. These pods operate in near-vacuum tubes, minimizing air resistance and enabling safe, automated freight movement that enhances supply chain reliability and lowers carbon emissions compared to conventional trucking and rail transport.

Intermodal Hyperloop Integration

Intermodal hyperloop integration revolutionizes logistics by combining traditional freight transport methods with ultra-fast, energy-efficient hyperloop systems to significantly reduce delivery times and operational costs. Enhanced coordination between rail, road, and hyperloop networks enables seamless cargo transfer, optimizing supply chain efficiency and minimizing environmental impact in transportation logistics.

Ultra-fast Last-Mile Delivery

Hyperloop logistics revolutionizes ultra-fast last-mile delivery by leveraging high-speed vacuum tube technology, drastically reducing transit times compared to traditional logistics networks reliant on road and rail transport. This innovation enables rapid supply chain responsiveness and real-time inventory management, essential for meeting growing consumer demands in urban environments.

Autonomous Tube Shipping

Autonomous Tube Shipping in hyperloop logistics offers unparalleled speed and efficiency compared to traditional logistics by utilizing vacuum-sealed tubes to transport cargo at near-supersonic speeds, drastically reducing transit times and operational costs. This innovative system enhances supply chain reliability and sustainability through automation and energy-efficient propulsion, setting a new standard in freight transportation.

Parcel Levitation Transport

Parcel levitation transport in hyperloop logistics significantly reduces friction and transit times compared to traditional logistics, enabling near-instantaneous movement of goods through low-pressure tubes. This advanced system enhances delivery efficiency, reliability, and sustainability by minimizing physical contact and energy consumption during transportation.

Vacuum-Sealed Logistics Corridors

Vacuum-sealed logistics corridors in hyperloop systems drastically reduce air resistance, enabling cargo to be transported at speeds up to 700 mph, far surpassing traditional logistics methods reliant on road, rail, or air transport. This innovation optimizes delivery times and energy efficiency, transforming supply chain dynamics by minimizing transit delays and operational costs.

Real-time Hyperloop Tracking

Real-time Hyperloop tracking leverages advanced IoT sensors and AI algorithms to monitor cargo conditions and location with unprecedented accuracy, drastically reducing delays compared to traditional logistics methods. This enhanced visibility enables proactive decision-making, optimizes supply chain efficiency, and minimizes transit times in Hyperloop logistics systems.

Goods Velocity Optimization

Traditional logistics systems optimize goods velocity through route planning, freight consolidation, and real-time tracking, yet face limitations due to traffic congestion and infrastructure constraints. Hyperloop logistics revolutionize goods velocity optimization by enabling near-supersonic transit speeds in low-pressure tubes, drastically reducing delivery times and enhancing supply chain efficiency.

Sustainable Tube Logistics

Sustainable Tube Logistics revolutionizes transportation by utilizing Hyperloop technology, dramatically reducing carbon emissions compared to traditional trucking and air freight. This system leverages magnetic levitation and low-pressure tubes to enable ultra-efficient, high-speed cargo movement, significantly lowering energy consumption and environmental impact in supply chain operations.

Logistics vs Hyperloop Logistics Infographic

industrydif.com

industrydif.com