Construction waste generates significant environmental impact due to the disposal of excess materials and debris from traditional building methods. Modular construction reuse minimizes waste by allowing prefabricated components to be repurposed or recycled efficiently, reducing landfill contributions. This method supports sustainable building practices by promoting material conservation and waste reduction throughout the construction lifecycle.

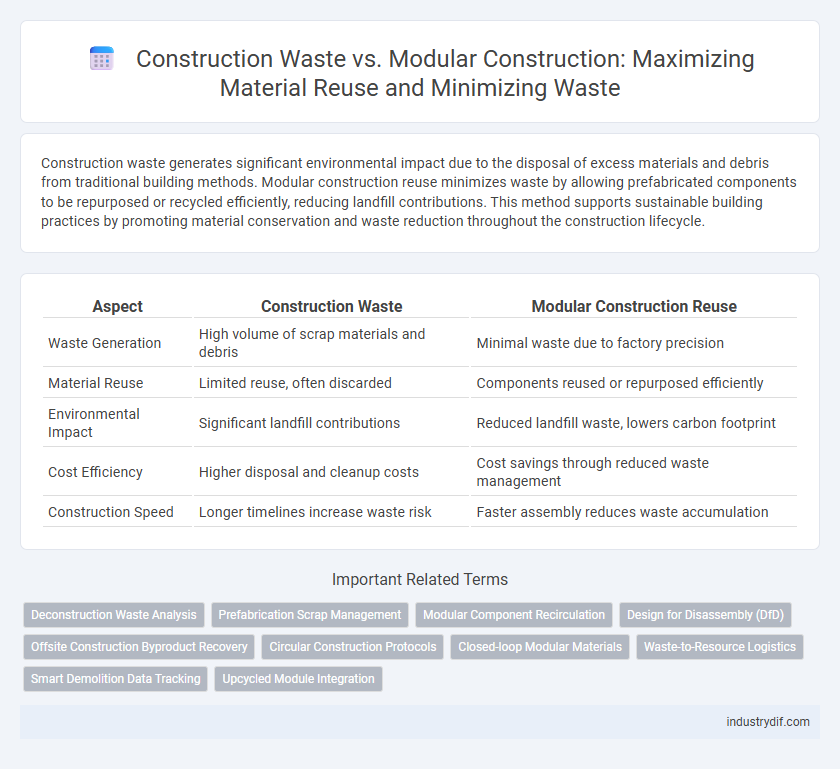

Table of Comparison

| Aspect | Construction Waste | Modular Construction Reuse |

|---|---|---|

| Waste Generation | High volume of scrap materials and debris | Minimal waste due to factory precision |

| Material Reuse | Limited reuse, often discarded | Components reused or repurposed efficiently |

| Environmental Impact | Significant landfill contributions | Reduced landfill waste, lowers carbon footprint |

| Cost Efficiency | Higher disposal and cleanup costs | Cost savings through reduced waste management |

| Construction Speed | Longer timelines increase waste risk | Faster assembly reduces waste accumulation |

Understanding Construction Waste: Key Industry Terms

Construction waste includes materials like concrete, wood, metals, and drywall discarded during building, renovation, or demolition projects. Modular construction reuse involves repurposing prefabricated components, significantly reducing material disposal and lowering environmental impact. Recognizing terms such as "deconstruction," "material diversion," and "circular construction" is essential for effectively managing and minimizing construction waste in the industry.

Modular Construction: Defining the Approach

Modular construction emphasizes assembling prefabricated components in controlled factory settings, significantly reducing on-site waste by minimizing material offcuts and errors. This approach promotes the reuse of standardized modules, enhancing resource efficiency and lowering overall construction waste generation compared to traditional building methods. By optimizing design and production processes, modular construction supports sustainable waste management and circular economy principles in the construction industry.

Types of Construction Waste Generated On-Site

Construction waste generated on-site predominantly includes concrete, wood, metals, drywall, and packaging materials. Modular construction reuse significantly reduces these waste types by fabricating components off-site under controlled environments, minimizing cutting and offcuts. This method not only lowers the volume of debris but also improves material recovery rates, promoting sustainable building practices.

Principles of Reuse in Modular Construction

Modular construction emphasizes the principles of reuse by incorporating standardized components that can be easily disassembled and repurposed, reducing construction waste significantly. The approach prioritizes designing for adaptability and dismantling, which minimizes material disposal and promotes circular material flows within the construction industry. By implementing these principles, modular construction enhances resource efficiency and supports sustainable building practices.

Material Efficiency: Traditional vs. Modular Methods

Construction waste accounts for approximately 30% of total waste generated globally, driven largely by inefficiencies in traditional building methods that result in excess material offcuts and demolition debris. Modular construction enhances material efficiency by using prefabricated components manufactured in controlled environments, reducing waste through precise cutting and optimized material usage by up to 90%. This approach not only minimizes landfill contributions but also promotes sustainable resource allocation in the construction industry.

Lifecycle Assessment of Construction Waste

Construction waste generates significant environmental impact throughout its lifecycle, from extraction to disposal, often resulting in high carbon emissions and resource depletion. Modular construction reuse minimizes waste generation by enabling offsite fabrication and efficient material recirculation, significantly reducing the embodied energy and landfill contributions in lifecycle assessments. Lifecycle assessment studies show modular approaches lower global warming potential and resource consumption compared to traditional construction waste management.

Regulatory Standards for Waste Management

Construction waste management is governed by stringent regulatory standards such as the U.S. Environmental Protection Agency (EPA) guidelines and the EU Waste Framework Directive, which emphasize reducing landfill disposal through recycling and reuse. Modular construction facilitates compliance by enabling precise material quantification and off-site fabrication, significantly minimizing waste generation and enabling higher rates of material reuse. Adherence to LEED certification criteria and ISO 14001 environmental management standards further incentivizes sustainable waste practices within modular construction projects.

Deconstruction vs. Demolition: Waste Implications

Deconstruction prioritizes careful dismantling of building components to maximize material reuse, significantly reducing construction waste compared to traditional demolition, which often results in large volumes of mixed debris sent to landfills. Modular construction emphasizes off-site fabrication and on-site assembly, facilitating material recovery and minimizing waste by allowing modules to be disassembled and reused. Implementing deconstruction techniques within modular construction frameworks optimizes circularity and mitigates environmental impacts associated with conventional demolition waste streams.

Benefits of Modular Construction for Waste Reduction

Modular construction significantly reduces waste by enabling precise factory-based manufacturing, which minimizes material offcuts and errors compared to traditional construction methods. Prefabrication in modular building allows for the reuse of components and recycling of excess materials, lowering landfill contributions and conserving resources. This waste-efficient process contributes to sustainable development by reducing the environmental impact of construction projects.

Future Trends: Circular Economy in Construction

Construction waste accounts for nearly 30% of total landfill mass, prompting a shift towards modular construction reuse to minimize environmental impact. Embracing circular economy principles, future trends emphasize design for disassembly, material recovery, and on-site waste reduction through prefabrication. Digitally integrated modular systems enable precise resource management, fostering sustainable building practices and reducing construction waste by up to 50%.

Related Important Terms

Deconstruction Waste Analysis

Deconstruction waste analysis reveals that modular construction significantly reduces the volume of construction debris by enabling precise dismantling and material segregation for reuse. Compared to traditional construction waste, modular methods lower landfill contributions, promote circular economy practices, and improve resource efficiency on-site.

Prefabrication Scrap Management

Prefabrication scrap from modular construction significantly reduces construction waste by allowing for precise material cutting and controlled manufacturing environments, minimizing excess off-cuts. Effective scrap management in modular construction involves recycling leftover materials on-site or redirecting them to secondary uses, enhancing sustainability compared to traditional construction waste disposal.

Modular Component Recirculation

Modular construction significantly reduces construction waste by enabling the recirculation of prefabricated components, which can be disassembled and reused across multiple projects, lowering landfill contributions. This approach enhances material efficiency, minimizes resource consumption, and supports sustainable building practices compared to traditional construction waste-heavy methods.

Design for Disassembly (DfD)

Design for Disassembly (DfD) significantly reduces construction waste by enabling modular components to be easily separated, reused, or recycled, minimizing landfill contributions. This approach contrasts with traditional construction, where materials are often permanently fixed, leading to higher demolition waste and lower resource recovery rates.

Offsite Construction Byproduct Recovery

Offsite construction significantly reduces construction waste by enabling precise material measurement and prefabrication, minimizing byproduct generation compared to traditional onsite methods. Modular construction reuse further enhances sustainability by reclaiming and repurposing components, leading to higher rates of offsite construction byproduct recovery and reduced landfill impact.

Circular Construction Protocols

Construction waste accounts for approximately 30% of global landfill mass, while modular construction reuse reduces material waste by up to 90% through prefabrication and standardized components. Circular construction protocols emphasize resource efficiency and lifecycle management, promoting the recycling and reuse of modular components to minimize environmental impact and advance sustainable building practices.

Closed-loop Modular Materials

Closed-loop modular materials enable the reuse of construction components, significantly reducing construction waste by recycling modules within the building lifecycle. This approach minimizes landfill contributions and lowers raw material demand compared to traditional construction waste disposal methods.

Waste-to-Resource Logistics

Construction waste accounts for approximately 30% of total solid waste globally, challenging traditional disposal methods and emphasizing the need for efficient waste-to-resource logistics. Modular construction reuse significantly reduces waste generation by enabling on-site deconstruction and systematic recycling processes, optimizing material recovery and transportation within circular economy frameworks.

Smart Demolition Data Tracking

Smart demolition data tracking enhances the efficiency of construction waste management by providing precise information on materials recovered during modular construction reuse projects. This technology supports circular economy practices by enabling accurate documentation, sorting, and redistribution of reusable components, significantly reducing landfill contributions and resource consumption.

Upcycled Module Integration

Construction waste generates over 530 million tons annually in the U.S., making up nearly 40% of total landfill waste; modular construction reuse significantly reduces this by integrating upcycled modules that repurpose materials like steel, wood, and concrete. Upcycled module integration enhances sustainability by minimizing material extraction, cutting carbon emissions by up to 50%, and promoting circular economy principles in the building industry.

Construction Waste vs Modular Construction Reuse Infographic

industrydif.com

industrydif.com