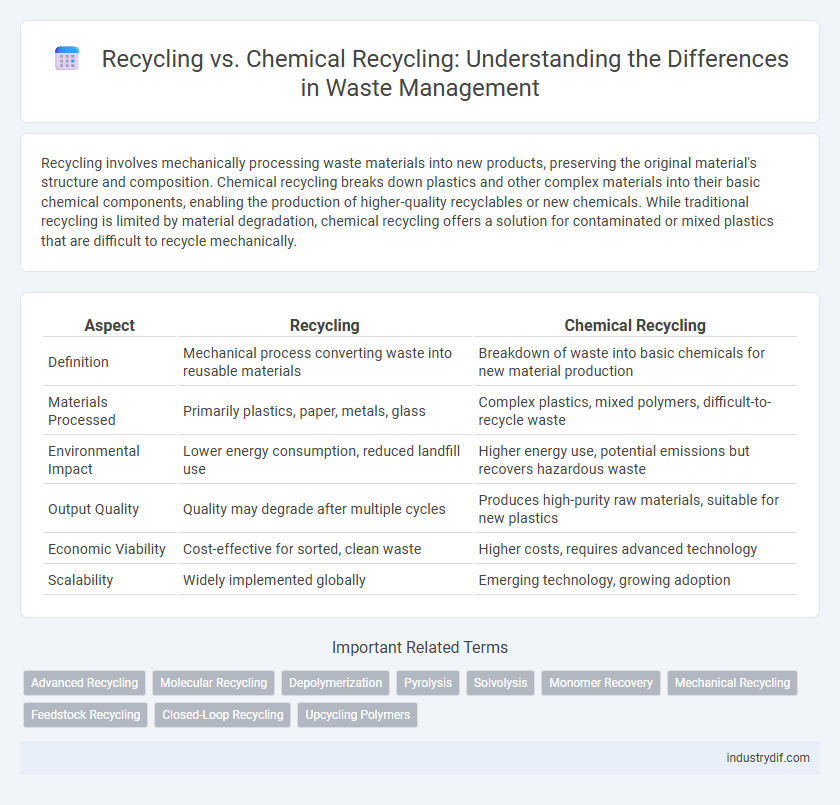

Recycling involves mechanically processing waste materials into new products, preserving the original material's structure and composition. Chemical recycling breaks down plastics and other complex materials into their basic chemical components, enabling the production of higher-quality recyclables or new chemicals. While traditional recycling is limited by material degradation, chemical recycling offers a solution for contaminated or mixed plastics that are difficult to recycle mechanically.

Table of Comparison

| Aspect | Recycling | Chemical Recycling |

|---|---|---|

| Definition | Mechanical process converting waste into reusable materials | Breakdown of waste into basic chemicals for new material production |

| Materials Processed | Primarily plastics, paper, metals, glass | Complex plastics, mixed polymers, difficult-to-recycle waste |

| Environmental Impact | Lower energy consumption, reduced landfill use | Higher energy use, potential emissions but recovers hazardous waste |

| Output Quality | Quality may degrade after multiple cycles | Produces high-purity raw materials, suitable for new plastics |

| Economic Viability | Cost-effective for sorted, clean waste | Higher costs, requires advanced technology |

| Scalability | Widely implemented globally | Emerging technology, growing adoption |

Introduction to Recycling and Chemical Recycling

Recycling involves the process of converting waste materials into reusable resources through mechanical methods, reducing environmental impact and conserving natural resources. Chemical recycling breaks down plastics and other materials at the molecular level, enabling recovery of raw materials that can be remanufactured into high-quality products. Both methods play crucial roles in sustainable waste management by minimizing landfill volume and promoting circular economy practices.

Defining Traditional Mechanical Recycling

Traditional mechanical recycling involves physically processing waste materials, primarily plastics, by sorting, cleaning, shredding, and melting them into new products without altering their chemical structure. This method preserves the polymer chains, making it efficient for materials like PET and HDPE but limited by contamination and thermal degradation. Mechanical recycling reduces landfill waste and energy consumption compared to virgin material production but struggles with complex or mixed plastic streams that chemical recycling aims to address.

Understanding Chemical Recycling Technologies

Chemical recycling technologies break down complex plastic polymers into their molecular building blocks, enabling the recovery of raw materials for producing new plastics with minimal quality loss. Unlike traditional mechanical recycling that physically processes waste, chemical recycling can handle mixed or contaminated plastics that are otherwise difficult to recycle. Advanced methods such as pyrolysis, gasification, and depolymerization enhance resource recovery and reduce landfill dependency by converting plastic waste into fuels, monomers, or other valuable chemicals.

Key Differences Between Mechanical and Chemical Recycling

Mechanical recycling processes waste plastics by physically grinding, melting, and remolding them without altering the chemical structure, making it efficient for clean, single-polymer materials. Chemical recycling breaks down polymers into their basic monomers or other valuable chemicals through processes like pyrolysis, depolymerization, or solvolysis, enabling the treatment of mixed, contaminated, or complex plastics. Mechanical recycling is limited by polymer degradation and contamination, while chemical recycling offers higher versatility and produces feedstock suitable for virgin-quality plastic production.

Environmental Impact: Mechanical vs Chemical Recycling

Mechanical recycling conserves energy by physically processing waste plastics into new products without altering their chemical structure, resulting in lower greenhouse gas emissions compared to chemical recycling. Chemical recycling breaks down polymers into monomers or other chemicals for reuse, enabling the recovery of mixed or contaminated plastics but typically requires higher energy input and generates more emissions. Evaluating environmental impact involves comparing mechanical recycling's efficiency and lower carbon footprint with chemical recycling's potential to reduce plastic waste landfill and pollution despite its greater energy consumption.

Efficiency and Yield: Mechanical vs Chemical Processes

Mechanical recycling employs physical processes like shredding and melting to recover materials, achieving a recovery rate of around 70-80% for plastics, while maintaining lower energy consumption compared to chemical recycling. Chemical recycling breaks down polymers into monomers or other chemicals through processes like pyrolysis or depolymerization, offering the potential for nearly 100% material yield but often requires higher energy inputs and complex operational conditions. Efficiency in mechanical recycling is constrained by material contamination and degradation, whereas chemical recycling can handle mixed or contaminated waste streams more effectively, though cost and scalability remain challenges.

Material Quality and End-Product Applications

Recycling preserves material quality by mechanically processing waste into reusable raw materials, maintaining structural integrity ideal for packaging and manufacturing. Chemical recycling breaks down plastics into monomers, enabling the production of high-purity end-products suitable for specialty chemicals and food-grade applications. Both methods contribute to waste reduction, with chemical recycling offering enhanced recovery of complex polymers that traditional recycling cannot effectively process.

Challenges and Limitations of Both Methods

Recycling faces challenges such as contamination of materials, limited types of plastics accepted, and high energy consumption during sorting and processing, which reduce efficiency and material quality. Chemical recycling encounters limitations including high operational costs, complex technology requirements, and potential environmental impacts from chemical use and emissions. Both methods struggle with scalability, inconsistent feedstock quality, and the need for improved infrastructure to make processes economically viable and environmentally sustainable.

Economic Viability and Market Adoption

Recycling relies on mechanical processes that are cost-effective and widely adopted, making it economically viable for large-scale operations with established markets. Chemical recycling, while capable of handling complex and contaminated waste streams, faces higher operational costs and limited commercial infrastructure, constraining its market adoption. Economic viability for chemical recycling improves with technological advancements and increased demand for circular materials in sectors like plastics and automotive industries.

Future Trends in Recycling Technologies

Emerging recycling technologies emphasize the growth of chemical recycling to complement traditional mechanical methods, enabling the breakdown of complex plastics into their molecular components. Advanced processes such as pyrolysis, gasification, and depolymerization offer promising routes to convert mixed and contaminated waste streams into valuable raw materials, reducing landfill dependence. Future trends prioritize scalability and energy efficiency improvements to integrate chemical recycling into circular economy models, enhancing material recovery and sustainability.

Related Important Terms

Advanced Recycling

Advanced recycling, also known as chemical recycling, breaks down plastics into their molecular components, enabling the recovery of high-quality materials that can be reused in manufacturing new products. Unlike traditional mechanical recycling, advanced recycling processes handle a broader range of plastic waste, including contaminated and mixed plastics, reducing landfill use and conserving natural resources.

Molecular Recycling

Molecular recycling, a subset of chemical recycling, breaks down polymers into their original monomers, enabling the production of virgin-quality plastics and reducing reliance on fossil fuels. Unlike mechanical recycling, which degrades plastic quality over cycles, molecular recycling offers sustainable waste management by effectively processing mixed or contaminated plastic streams.

Depolymerization

Recycling primarily involves mechanical processes that physically break down waste materials, whereas chemical recycling, particularly depolymerization, reverses polymers into their monomers, enabling the recovery of original chemical building blocks for polymer synthesis. Depolymerization enhances circularity by converting complex plastics like PET and polystyrene into high-purity feedstocks, significantly reducing resource consumption and environmental impact compared to traditional recycling methods.

Pyrolysis

Pyrolysis, a chemical recycling process, thermally decomposes plastic waste at high temperatures in the absence of oxygen, converting polymers into valuable fuels and raw materials, unlike traditional mechanical recycling which physically reprocesses plastics but often results in material degradation. This technology offers a sustainable solution for managing mixed or contaminated plastic waste streams, enhancing the circular economy by recovering energy and chemical feedstocks from otherwise non-recyclable plastics.

Solvolysis

Solvolysis, a chemical recycling method, uses solvents to break down polymers into their monomers, allowing for higher-quality material recovery compared to traditional mechanical recycling, which often degrades plastic properties. This process enhances circularity in waste management by enabling the reuse of plastics that are otherwise difficult to recycle mechanically, contributing to reduced landfill waste and lower environmental impact.

Monomer Recovery

Chemical recycling enables efficient monomer recovery by breaking down polymers into their original monomers, unlike traditional recycling which often results in lower-quality materials due to mechanical degradation. This process enhances circularity in plastic waste management by facilitating the production of high-purity monomers for new polymer synthesis.

Mechanical Recycling

Mechanical recycling preserves the physical properties of waste materials by shredding and melting plastics while maintaining polymer integrity, contrasting with chemical recycling that breaks down polymers into monomers through depolymerization. This process is energy-efficient, cost-effective, and widely implemented in managing post-consumer plastic waste streams, enhancing circular economy initiatives by reducing landfill reliance.

Feedstock Recycling

Feedstock recycling involves breaking down plastic waste into its chemical components, enabling the production of new polymers with properties comparable to virgin materials, unlike traditional mechanical recycling that often degrades material quality. This process enhances the circular economy by converting mixed or contaminated plastics into valuable raw materials, reducing reliance on fossil fuels and minimizing landfill waste.

Closed-Loop Recycling

Closed-loop recycling involves converting waste materials back into the same product, maintaining material quality and reducing resource extraction, while traditional recycling often downgrades quality, limiting reuse options. Chemical recycling breaks down plastics into monomers or feedstocks, enabling high-quality closed-loop recycling by restoring material purity and extending product lifecycle efficiency.

Upcycling Polymers

Recycling traditional polymers involves mechanical processing that often degrades material quality, whereas chemical recycling upcycles polymers by breaking them down into monomers for repolymerization, preserving material properties and enabling circular plastic economies. Chemical recycling methods such as pyrolysis, solvolysis, and depolymerization offer higher purity outputs and greater flexibility in handling mixed plastic waste streams, reducing landfill dependency and environmental impact.

Recycling vs Chemical Recycling Infographic

industrydif.com

industrydif.com