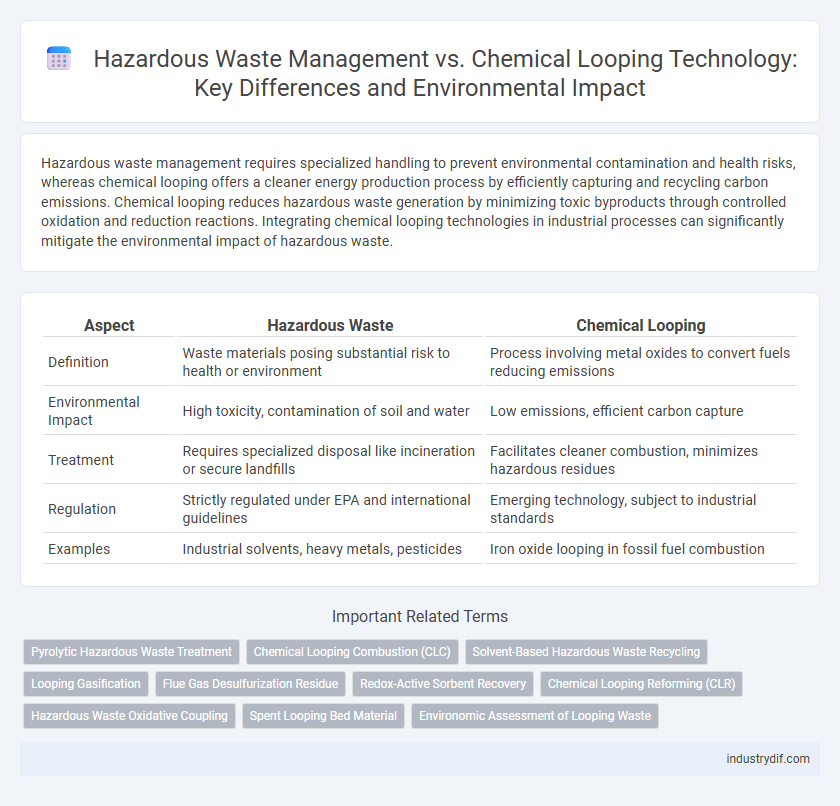

Hazardous waste management requires specialized handling to prevent environmental contamination and health risks, whereas chemical looping offers a cleaner energy production process by efficiently capturing and recycling carbon emissions. Chemical looping reduces hazardous waste generation by minimizing toxic byproducts through controlled oxidation and reduction reactions. Integrating chemical looping technologies in industrial processes can significantly mitigate the environmental impact of hazardous waste.

Table of Comparison

| Aspect | Hazardous Waste | Chemical Looping |

|---|---|---|

| Definition | Waste materials posing substantial risk to health or environment | Process involving metal oxides to convert fuels reducing emissions |

| Environmental Impact | High toxicity, contamination of soil and water | Low emissions, efficient carbon capture |

| Treatment | Requires specialized disposal like incineration or secure landfills | Facilitates cleaner combustion, minimizes hazardous residues |

| Regulation | Strictly regulated under EPA and international guidelines | Emerging technology, subject to industrial standards |

| Examples | Industrial solvents, heavy metals, pesticides | Iron oxide looping in fossil fuel combustion |

Defining Hazardous Waste and Chemical Looping

Hazardous waste refers to materials discarded as unwanted that pose substantial or potential threats to public health or the environment due to their toxic, reactive, ignitable, or corrosive properties. Chemical looping is an innovative process in energy production and waste management that utilizes metal oxides as oxygen carriers to convert fuels into energy with inherent carbon capture. Defining hazardous waste highlights its environmental risks, while chemical looping emphasizes a sustainable technology designed to minimize hazardous emissions.

Key Differences Between Hazardous Waste and Chemical Looping

Hazardous waste refers to materials that pose substantial risks to human health or the environment due to their toxic, corrosive, ignitable, or reactive properties, requiring strict disposal protocols under environmental regulations such as the Resource Conservation and Recovery Act (RCRA). Chemical looping is an innovative combustion technology that uses metal oxides as oxygen carriers to convert fuels into energy with inherent carbon capture, minimizing pollutant emissions and avoiding the generation of hazardous waste. The key differences lie in hazardous waste being a byproduct necessitating careful handling, whereas chemical looping is a process designed to reduce waste and improve environmental sustainability through efficient fuel conversion.

Sources and Composition of Hazardous Waste

Hazardous waste primarily originates from industrial processes, medical facilities, chemical manufacturing, and agricultural activities, containing toxic, corrosive, ignitable, or reactive substances that pose significant environmental and health risks. Its composition often includes heavy metals, solvents, pesticides, and assorted chemical byproducts, requiring specialized treatment and disposal methods. Chemical looping offers a sustainable approach by capturing and recycling reactive chemical components, reducing the generation of hazardous waste and facilitating resource recovery.

Principles and Processes of Chemical Looping

Chemical looping is an advanced process that minimizes hazardous waste by using metal oxides as oxygen carriers to convert fuels into energy without direct contact between fuel and air. This cyclical mechanism separates combustion and oxidation in distinct reactors, reducing the emission of pollutants and facilitating carbon capture. The principle relies on redox reactions where the metal oxide transfers oxygen to the fuel, producing a concentrated stream of CO2 and water, enhancing waste management efficiency compared to traditional hazardous waste treatment methods.

Environmental Impacts: Hazardous Waste vs Chemical Looping

Hazardous waste poses significant environmental risks due to the release of toxic substances that contaminate soil, water, and air, leading to long-term ecological damage and human health hazards. Chemical looping technology minimizes environmental impacts by enabling cleaner energy production with reduced greenhouse gas emissions and lower pollutant discharge, promoting sustainable industrial processes. Comparing the two, chemical looping offers a safer, more eco-friendly alternative to hazardous waste disposal, emphasizing reduced contamination and enhanced resource efficiency.

Regulatory Frameworks and Compliance Standards

Hazardous waste management is governed by stringent regulatory frameworks such as the Resource Conservation and Recovery Act (RCRA) in the U.S. and the EU Waste Framework Directive, which mandate strict compliance standards to prevent environmental contamination and human health risks. Chemical looping, an emerging technology for waste-to-energy conversion, must adhere to these existing hazardous waste regulations while demonstrating compliance with emissions standards and process safety protocols. Ensuring regulatory alignment of chemical looping processes involves continuous monitoring, reporting, and adapting to evolving environmental policies to mitigate hazardous waste risks effectively.

Treatment and Disposal Methods for Hazardous Waste

Hazardous waste treatment and disposal methods include incineration, chemical neutralization, and secure landfilling, designed to minimize environmental and health risks. Advanced techniques such as stabilization and solidification are employed to immobilize toxic substances, preventing leachate contamination. Chemical looping offers an innovative approach by facilitating waste-to-energy conversion and reducing emissions, although it is primarily applied in energy production rather than direct hazardous waste disposal.

Chemical Looping in Waste-to-Energy Conversion

Chemical looping offers a sustainable approach in waste-to-energy conversion by utilizing metal oxides to facilitate combustion without direct contact between fuel and air, significantly reducing hazardous emissions. This process enables efficient energy recovery from various waste streams while minimizing the release of toxic substances commonly found in hazardous waste incineration. By integrating chemical looping technology, waste management systems can achieve cleaner energy production and lower environmental impact compared to traditional hazardous waste treatment methods.

Safety Concerns and Risk Management

Hazardous waste poses significant safety concerns due to its toxicity, flammability, and corrosiveness, requiring stringent handling and disposal protocols to mitigate environmental and health risks. Chemical looping technology enhances risk management by enabling the containment and recycling of reactive substances within a closed system, reducing exposure and potential accidents during waste processing. Implementing chemical looping in hazardous waste treatment improves operational safety by minimizing emissions and preventing uncontrolled reactions, thus aligning with regulatory compliance and sustainable waste management practices.

Future Trends in Waste Management Technologies

Hazardous waste management is increasingly integrated with chemical looping technologies to enhance environmental safety and resource recovery. Chemical looping offers a sustainable approach by enabling the continuous conversion of hazardous waste into useful energy and chemicals, reducing emissions and landfill dependency. Future trends emphasize scalable, cost-effective chemical looping reactors combined with advanced monitoring systems to optimize waste valorization and minimize ecological impact.

Related Important Terms

Pyrolytic Hazardous Waste Treatment

Pyrolytic hazardous waste treatment utilizes thermal decomposition in an oxygen-limited environment to break down toxic compounds, significantly reducing the volume and toxicity of hazardous waste. Chemical looping enhances this process by enabling efficient capture and recycling of gases produced during pyrolysis, minimizing emissions and improving waste-to-energy conversion efficiency.

Chemical Looping Combustion (CLC)

Chemical Looping Combustion (CLC) offers a sustainable alternative to hazardous waste disposal by utilizing metal oxide particles to transfer oxygen for fuel combustion, effectively capturing CO2 and minimizing toxic emissions. This process enhances clean energy production while significantly reducing the environmental risks associated with hazardous chemical waste.

Solvent-Based Hazardous Waste Recycling

Solvent-based hazardous waste recycling utilizes chemical looping technology to efficiently separate and recover valuable solvents, reducing environmental contamination and minimizing landfill disposal. This process enhances resource recovery by converting hazardous solvent waste into reusable materials, promoting sustainable waste management practices.

Looping Gasification

Hazardous waste management benefits from chemical looping gasification by enabling efficient conversion of toxic materials into syngas while minimizing harmful emissions. This advanced process uses oxygen carriers to facilitate gasification reactions, significantly reducing the release of hazardous pollutants compared to conventional methods.

Flue Gas Desulfurization Residue

Flue Gas Desulfurization Residue (FGD) is classified as hazardous waste due to its high levels of toxic heavy metals and acidic components, requiring careful management to prevent environmental contamination. Chemical looping technology offers a sustainable solution by enabling the recovery and reuse of sulfur compounds from FGD, reducing hazardous waste generation and minimizing disposal challenges.

Redox-Active Sorbent Recovery

Hazardous waste management benefits from chemical looping technology by enabling efficient redox-active sorbent recovery, which reduces toxic residue and promotes sustainable reuse of sorbents. This approach minimizes environmental impact by facilitating reversible oxidation-reduction cycles that regenerate sorbents while capturing hazardous contaminants effectively.

Chemical Looping Reforming (CLR)

Chemical Looping Reforming (CLR) offers a sustainable alternative for managing hazardous waste by converting organic contaminants into useful syngas through selective oxygen carriers, significantly reducing toxic emissions. The CLR process enhances energy efficiency and minimizes environmental impact compared to conventional hazardous waste treatments, promoting cleaner waste-to-energy conversion.

Hazardous Waste Oxidative Coupling

Hazardous waste oxidative coupling involves using advanced oxidation processes to convert toxic organic compounds into less harmful substances, reducing environmental risks. Chemical looping techniques enhance this process by providing a controlled environment for oxidation reactions, improving efficiency and minimizing secondary pollution.

Spent Looping Bed Material

Spent looping bed material in chemical looping processes is categorized as hazardous waste due to the presence of residual metal oxides and contaminants that pose environmental and health risks; its proper management requires advanced treatment and disposal techniques to prevent toxic leachate and air pollution. Efficient recycling and stabilization methods for spent looping bed material can minimize hazardous waste generation and promote sustainable chemical looping technology applications in industrial waste management.

Environomic Assessment of Looping Waste

Hazardous waste management through chemical looping offers a promising environomic assessment by significantly reducing toxic emissions and improving resource recovery efficiency. This process minimizes environmental impact and operational costs compared to conventional hazardous waste disposal methods, enhancing sustainable waste treatment solutions.

Hazardous Waste vs Chemical Looping Infographic

industrydif.com

industrydif.com