Traditional waste sorting relies on manual labor and simple mechanical processes, often resulting in inefficiencies and higher contamination rates. AI-powered waste sorting leverages advanced machine learning algorithms and sensor technologies to accurately identify and separate materials, significantly improving recycling rates and reducing operational costs. This innovative approach enhances sustainability by optimizing resource recovery and minimizing landfill waste.

Table of Comparison

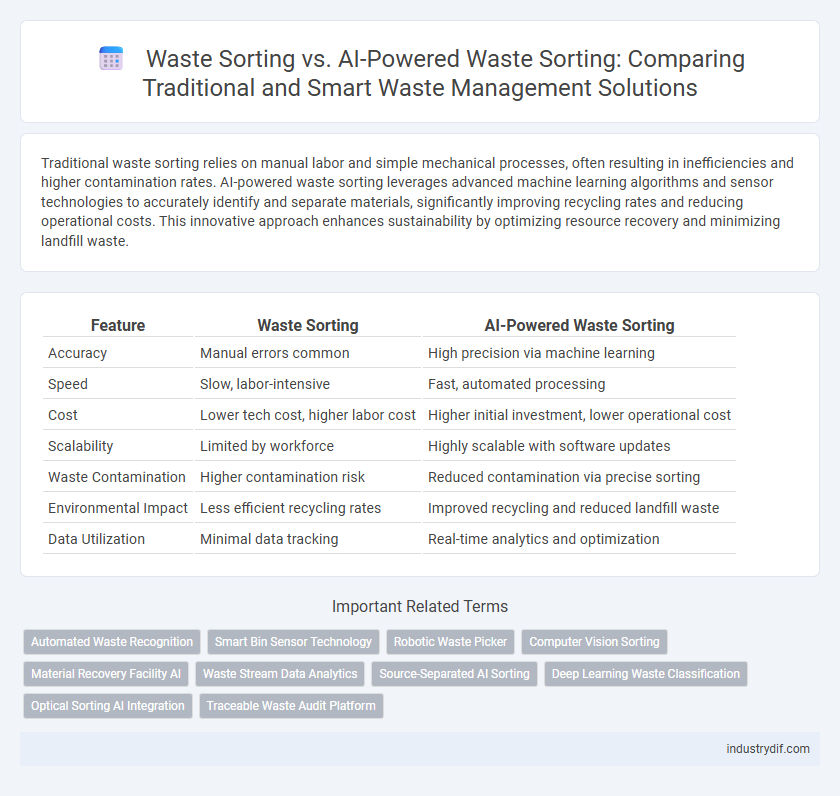

| Feature | Waste Sorting | AI-Powered Waste Sorting |

|---|---|---|

| Accuracy | Manual errors common | High precision via machine learning |

| Speed | Slow, labor-intensive | Fast, automated processing |

| Cost | Lower tech cost, higher labor cost | Higher initial investment, lower operational cost |

| Scalability | Limited by workforce | Highly scalable with software updates |

| Waste Contamination | Higher contamination risk | Reduced contamination via precise sorting |

| Environmental Impact | Less efficient recycling rates | Improved recycling and reduced landfill waste |

| Data Utilization | Minimal data tracking | Real-time analytics and optimization |

Introduction to Waste Sorting

Waste sorting involves separating recyclable, compostable, and landfill-bound materials at the source to improve recovery rates and reduce contamination. Traditional waste sorting relies heavily on manual labor and basic mechanical processes, which can be inefficient and error-prone. AI-powered waste sorting utilizes advanced computer vision and machine learning algorithms to accurately identify and classify waste types, increasing efficiency and enabling higher-quality recycling.

Traditional Waste Sorting Methods

Traditional waste sorting methods rely heavily on manual labor and simple mechanical processes to separate recyclables, organic waste, and landfill materials. These techniques often suffer from lower accuracy and efficiency due to human error and limited scalability in handling large volumes of heterogeneous waste. Despite being cost-effective for small-scale operations, conventional sorting struggles to meet the demands of modern waste management systems requiring higher precision and speed.

Limitations of Manual Waste Sorting

Manual waste sorting struggles with inconsistent separation due to human error, leading to contamination and reduced recycling efficiency. It is time-consuming and labor-intensive, limiting scalability in large waste management systems. In contrast, AI-powered waste sorting leverages advanced sensors and machine learning algorithms to accurately identify and categorize materials, enhancing sorting speed and reliability.

Emergence of AI-Powered Waste Sorting Technologies

AI-powered waste sorting technologies utilize advanced sensors, machine learning algorithms, and robotics to accurately identify and separate recyclable materials from waste streams. These innovations enhance sorting efficiency, reduce human error, and increase the recovery rate of valuable resources. Emerging AI systems integrate real-time data analysis and automated decision-making, transforming traditional waste management into a smarter, more sustainable process.

Key Components of AI Waste Sorting Systems

AI-powered waste sorting systems utilize advanced sensors, machine learning algorithms, and robotic arms to accurately identify and separate recyclables from waste streams. Key components include hyperspectral cameras for material recognition, neural networks for data processing, and automated conveyance systems that enhance sorting speed and precision. These technologies enable higher sorting efficiency, reduce contamination rates, and improve the overall recycling process compared to traditional manual or mechanical sorting methods.

Efficiency Comparison: Manual vs AI-Powered Sorting

Manual waste sorting relies on human labor and is limited by speed, accuracy, and fatigue, resulting in lower overall efficiency and increased contamination rates. AI-powered waste sorting systems utilize machine learning algorithms and advanced sensors to identify, categorize, and separate materials with higher precision and faster processing times. These automated solutions significantly reduce sorting errors and operational costs, enhancing recycling rates and waste management efficiency on a large scale.

Environmental Impact: Traditional vs AI Sorting

Traditional waste sorting relies heavily on manual labor and basic mechanical processes, often resulting in lower accuracy and higher contamination rates that negatively affect recycling efficiency and increase landfill use. AI-powered waste sorting uses advanced sensors, machine learning, and computer vision to significantly improve sorting precision, which enhances material recovery rates and reduces greenhouse gas emissions from waste processing. This increased efficiency directly contributes to conserving natural resources and minimizing environmental pollution compared to conventional methods.

Operational Costs and ROI Analysis

AI-powered waste sorting significantly reduces operational costs by automating material identification and separation, leading to faster processing speeds and decreased labor expenses compared to traditional manual sorting methods. Enhanced accuracy in AI systems minimizes contamination and increases the value of sorted recyclables, positively impacting the overall return on investment (ROI). Companies adopting AI-driven sorting technologies report improved efficiency and long-term cost savings, making the initial capital expenditure justifiable through higher throughput and reduced waste management fees.

Case Studies: Successful AI Waste Sorting Implementations

Case studies of AI-powered waste sorting showcase significant improvements in accuracy and efficiency compared to traditional sorting methods, with automated systems achieving up to 95% contamination reduction in recyclable streams. For example, Singapore's Solid Waste Management Facility implemented AI-driven robotics that increased material recovery rates by 30%, while Barcelona's smart waste program utilized machine learning algorithms to optimize sorting processes, resulting in a 25% decrease in landfill waste. These successful implementations highlight the transformative potential of AI technologies in advancing sustainable waste management practices worldwide.

Future Trends in AI-Driven Waste Management

AI-powered waste sorting leverages advanced machine learning algorithms and computer vision to enhance accuracy and efficiency compared to traditional manual sorting methods. Future trends in AI-driven waste management include the integration of IoT sensors for real-time waste composition analysis and robotic automation to reduce human error and operational costs. These innovations aim to optimize recycling rates, minimize landfill dependency, and promote circular economy practices by enabling smarter resource recovery.

Related Important Terms

Automated Waste Recognition

Automated waste recognition leverages AI-powered waste sorting systems that use computer vision and machine learning algorithms to accurately identify and classify recyclable materials, enhancing sorting efficiency and reducing human error. Traditional waste sorting relies on manual labor, leading to slower processing times and higher contamination rates, whereas AI-driven solutions streamline operations and improve recycling rates through real-time data analysis and precise waste categorization.

Smart Bin Sensor Technology

Smart bin sensor technology enhances traditional waste sorting by using AI-powered sensors to accurately identify and separate recyclable materials in real time, reducing contamination and improving recycling rates. This advanced system leverages machine learning algorithms and optical sensors to optimize waste management efficiency and promote sustainable resource recovery.

Robotic Waste Picker

Robotic waste pickers utilize AI-powered sensors and machine learning algorithms to achieve higher precision in sorting recyclable materials compared to traditional waste sorting methods, significantly reducing contamination rates and improving recycling efficiency. Advanced vision systems enable these robots to identify and separate diverse waste types quickly, enhancing overall waste management processes and promoting sustainability.

Computer Vision Sorting

Waste sorting leverages manual or automated processes to separate recyclable materials, while AI-powered waste sorting utilizes advanced computer vision algorithms to identify and classify waste with higher accuracy and speed. Computer vision sorting enhances efficiency by analyzing shape, color, and texture in real-time, reducing contamination rates and optimizing recycling streams.

Material Recovery Facility AI

Material Recovery Facility AI enhances traditional waste sorting by using machine learning algorithms and advanced sensors to accurately identify and separate recyclables from mixed waste streams, significantly increasing recovery rates and reducing contamination. This AI-driven technology optimizes operational efficiency, lowers labor costs, and supports circular economy goals by enabling higher-quality material output for reuse and recycling processes.

Waste Stream Data Analytics

Waste stream data analytics enhances traditional waste sorting by leveraging AI algorithms to identify, classify, and optimize the processing of diverse materials with higher accuracy and efficiency. AI-powered waste sorting systems utilize real-time data to reduce contamination rates, improve recycling outputs, and enable dynamic adjustments in waste management operations based on predictive insights.

Source-Separated AI Sorting

Source-separated AI sorting leverages machine learning algorithms to accurately identify and categorize recyclable materials directly at the source, significantly reducing contamination rates compared to traditional manual sorting. This technology enhances efficiency and sustainability by automating sorting processes, enabling higher recovery of valuable resources and minimizing waste sent to landfills.

Deep Learning Waste Classification

Traditional waste sorting relies on manual identification and separation, often limited by human error and inconsistent categorization. AI-powered waste sorting employs deep learning algorithms to analyze complex visual data, enabling precise classification of materials and improving recycling efficiency through automated decision-making.

Optical Sorting AI Integration

Optical sorting technology enhances waste sorting efficiency by using AI-powered image recognition to accurately identify and separate recyclable materials based on color, shape, and composition. Integrating AI into optical sorting systems reduces contamination rates and increases throughput, optimizing recycling processes and minimizing landfill waste.

Traceable Waste Audit Platform

Waste sorting enhances material recovery by manually categorizing recyclables, but AI-powered waste sorting integrates advanced sensors and machine learning to increase accuracy and efficiency. A traceable waste audit platform leverages AI technology to monitor and document waste streams in real time, enabling precise reporting, compliance, and optimized resource management.

Waste Sorting vs AI-Powered Waste Sorting Infographic

industrydif.com

industrydif.com