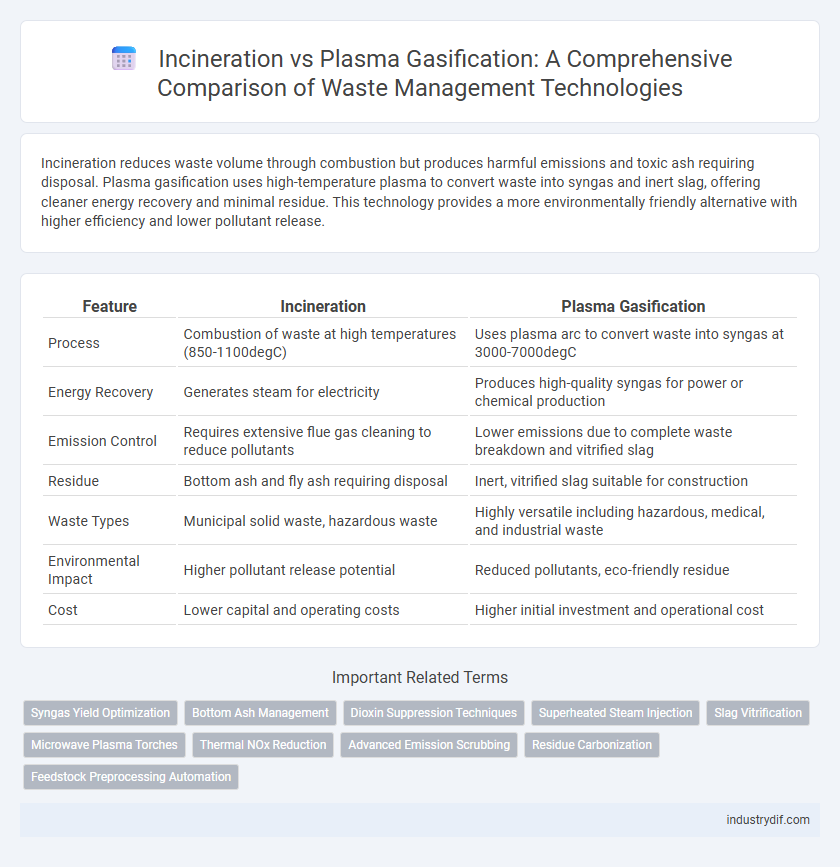

Incineration reduces waste volume through combustion but produces harmful emissions and toxic ash requiring disposal. Plasma gasification uses high-temperature plasma to convert waste into syngas and inert slag, offering cleaner energy recovery and minimal residue. This technology provides a more environmentally friendly alternative with higher efficiency and lower pollutant release.

Table of Comparison

| Feature | Incineration | Plasma Gasification |

|---|---|---|

| Process | Combustion of waste at high temperatures (850-1100degC) | Uses plasma arc to convert waste into syngas at 3000-7000degC |

| Energy Recovery | Generates steam for electricity | Produces high-quality syngas for power or chemical production |

| Emission Control | Requires extensive flue gas cleaning to reduce pollutants | Lower emissions due to complete waste breakdown and vitrified slag |

| Residue | Bottom ash and fly ash requiring disposal | Inert, vitrified slag suitable for construction |

| Waste Types | Municipal solid waste, hazardous waste | Highly versatile including hazardous, medical, and industrial waste |

| Environmental Impact | Higher pollutant release potential | Reduced pollutants, eco-friendly residue |

| Cost | Lower capital and operating costs | Higher initial investment and operational cost |

Introduction to Waste Treatment Technologies

Incineration and plasma gasification are advanced waste treatment technologies designed to reduce landfill dependency while recovering energy. Incineration uses high-temperature combustion to convert waste into ash, flue gases, and heat, commonly applied for municipal solid waste management. Plasma gasification operates at ultra-high temperatures using plasma torches to convert waste into syngas and vitrified slag, offering higher energy recovery and reduced emissions compared to traditional incineration.

What is Incineration?

Incineration is a waste treatment process that combusts organic materials at high temperatures, reducing waste volume by up to 90% and converting it into ash, flue gas, and heat. This method is widely used for municipal solid waste, hazardous waste, and medical waste, producing energy through waste-to-energy facilities. Despite concerns about emissions, modern incinerators employ advanced air pollution control technologies to minimize the release of dioxins, furans, and particulate matter.

Understanding Plasma Gasification

Plasma gasification converts waste into syngas and molten slag using extremely high temperatures generated by plasma torches, offering a cleaner alternative to traditional incineration by minimizing toxic emissions and maximizing energy recovery. This process breaks down organic materials at the molecular level, producing a synthesis gas rich in hydrogen and carbon monoxide that can be utilized for power generation or chemical synthesis. Compared to incineration, plasma gasification significantly reduces the volume of residual ash and hazardous byproducts, enhancing environmental sustainability in waste management.

Key Differences Between Incineration and Plasma Gasification

Incineration involves burning waste at high temperatures to reduce volume and generate energy, producing ash and emissions as byproducts. Plasma gasification uses an electric arc to create plasma, converting waste into synthesis gas with minimal residuals and lower emissions. The primary differences lie in emission levels, energy efficiency, and the type of waste transformed into usable byproducts.

Environmental Impact: Incineration vs Plasma Gasification

Incineration emits higher levels of dioxins, furans, and particulate matter, contributing significantly to air pollution and greenhouse gas emissions. Plasma gasification produces fewer emissions by using extreme temperatures to break down waste into syngas and slag, resulting in minimal toxic residues and lower carbon footprints. The advanced containment and conversion process of plasma gasification offers a more environmentally sustainable alternative to conventional incineration methods.

Energy Recovery and Efficiency Comparison

Plasma gasification achieves higher energy recovery rates than conventional incineration by converting waste into synthetic gas with lower emissions and higher calorific value. Incineration typically operates at lower thermal efficiency, around 20-30%, whereas plasma gasification can reach energy conversion efficiencies exceeding 35-40%. The advanced temperature control and reduced toxic byproducts in plasma gasification enhance overall system efficiency and environmental performance.

Emissions and Pollution Control

Incineration releases significant amounts of dioxins, furans, and particulate matter despite advanced scrubbers, contributing to air pollution and health risks. Plasma gasification operates at higher temperatures, effectively breaking down toxic compounds into synthesis gas with minimal hazardous emissions and reduced need for post-treatment. Emission controls in plasma gasification typically outperform incineration by generating fewer pollutants and producing a cleaner byproduct, enhancing environmental sustainability.

Costs and Economic Considerations

Incineration incurs lower initial capital costs but higher long-term operational expenses due to emissions control and ash disposal, while plasma gasification demands significant upfront investment but benefits from higher energy efficiency and reduced waste residues. Plasma gasification offers potential revenue streams from synthetic gas and byproducts, enhancing economic viability over time compared to traditional incineration methods. Evaluating cost-effectiveness depends on waste composition, scale, regulatory environment, and potential for resource recovery in each technology.

Technological Advancements and Limitations

Incineration remains a widely used waste-to-energy method due to its maturity and ability to reduce waste volume by up to 90%, but it faces challenges such as high emissions of dioxins and limited energy recovery efficiency. Plasma gasification offers technological advancements through its use of extremely high temperatures exceeding 3,000degC, resulting in nearly complete waste decomposition and the production of syngas with higher calorific value and lower toxic byproducts. Limitations of plasma gasification include significant capital costs, complex operational requirements, and limited commercial-scale deployments compared to incineration's established infrastructure.

Future Trends in Waste Disposal Solutions

Plasma gasification is emerging as a cutting-edge waste disposal method, offering higher energy recovery and lower emissions compared to traditional incineration. Innovations in plasma technology emphasize scalability and integration with renewable energy systems, aligning with sustainability goals and circular economy principles. Future trends point toward combining plasma gasification with carbon capture and advanced sorting technologies to maximize efficiency and minimize environmental impact in waste management.

Related Important Terms

Syngas Yield Optimization

Plasma gasification outperforms incineration in syngas yield optimization by producing higher concentrations of hydrogen and carbon monoxide due to its high-temperature, low-oxygen environment, which minimizes tar and particulate formation. Incineration typically results in lower-quality syngas with higher contamination levels, making plasma gasification a more efficient technology for clean energy recovery from waste.

Bottom Ash Management

Incineration produces bottom ash that typically requires landfilling or further treatment to recover metals and reduce leachate hazards, whereas plasma gasification generates vitrified slag with minimal leachate risk, enabling safer recycling in construction materials. Effective bottom ash management in plasma gasification enhances environmental performance by reducing toxic residue and promoting circular economy principles.

Dioxin Suppression Techniques

Incineration dioxin suppression relies on rapid cooling and activated carbon injection to prevent toxic emissions, while plasma gasification minimizes dioxin formation through extremely high temperatures exceeding 3,000degC that break down hazardous compounds at the molecular level. Advanced plasma reactors achieve near-complete destruction of persistent organic pollutants, outperforming conventional incinerators in reducing harmful dioxin and furan output.

Superheated Steam Injection

Superheated steam injection in incineration enhances combustion efficiency by increasing temperature and reducing harmful emissions, improving waste-to-energy conversion rates. Plasma gasification employs superheated steam to assist in breaking down complex waste molecules into syngas, resulting in higher energy recovery and lower toxic byproducts compared to traditional incineration.

Slag Vitrification

Plasma gasification achieves superior slag vitrification compared to traditional incineration by subjecting waste to extremely high temperatures above 3,000degC, resulting in fully molten slag that cools into a stable, glass-like, non-leachable material ideal for safe landfilling or construction use. Incineration typically produces partially melted slag with higher leachability and lower structural integrity, making plasma gasification a more effective technology for reducing hazardous byproducts and promoting sustainable waste management.

Microwave Plasma Torches

Microwave plasma torches in plasma gasification produce ultra-high temperatures exceeding 10,000degC, enabling more efficient and complete breakdown of waste compared to traditional incineration methods, which typically operate at lower temperatures around 850-1,100degC. This advanced thermal technology significantly reduces the formation of toxic emissions such as dioxins and furans while maximizing syngas quality for energy recovery and minimizing residual ash volume.

Thermal NOx Reduction

Plasma gasification achieves significantly lower thermal NOx emissions compared to incineration by operating at higher temperatures with limited oxygen, which minimizes nitrogen oxidation. Advanced plasma torches create an oxygen-starved environment that suppresses thermal NOx formation, enhancing environmental compliance and reducing air pollution.

Advanced Emission Scrubbing

Incineration systems often rely on conventional scrubbers that remove particulates and some gaseous pollutants but may emit dioxins and heavy metals, whereas plasma gasification employs advanced emission scrubbing technologies such as alkaline scrubbing and activated carbon injection to achieve higher removal efficiencies of toxic compounds and volatile organic compounds. Plasma gasification's high-temperature environment, combined with sophisticated gas cleaning systems, significantly reduces harmful emissions, making it a more environmentally sustainable waste treatment option compared to traditional incineration.

Residue Carbonization

Incineration reduces waste volume by burning at high temperatures but leaves significant residue requiring landfill, whereas plasma gasification converts waste into synthetic gas and solid slag through carbonization at ultra-high temperatures, minimizing residual ash. Residue carbonization in plasma gasification produces a stable, non-toxic byproduct that can be repurposed, offering a more sustainable waste management solution compared to traditional incineration.

Feedstock Preprocessing Automation

Incineration systems require minimal feedstock preprocessing, often accepting mixed municipal solid waste with basic sorting, while plasma gasification demands advanced automated preprocessing to separate materials and optimize feedstock uniformity for efficient plasma arc reactions. Automated sorting technologies, including robotic arms and sensor-based identification, enhance plasma gasification feedstock quality, reducing contaminants and improving gas synthesis outcomes compared to the less automated processes used in incineration.

Incineration vs Plasma Gasification Infographic

industrydif.com

industrydif.com