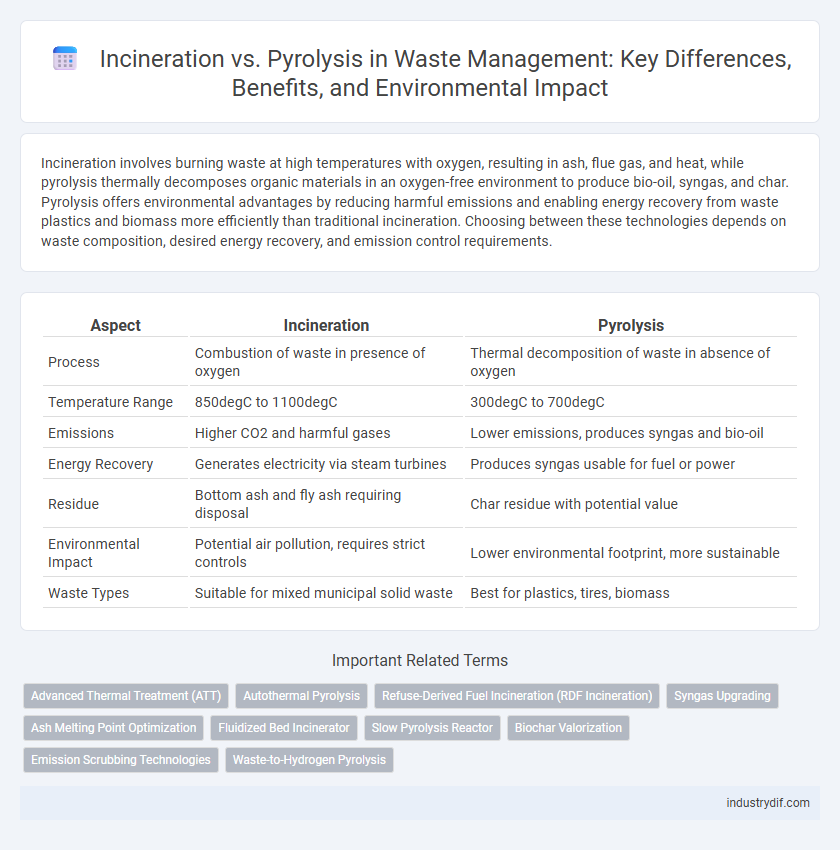

Incineration involves burning waste at high temperatures with oxygen, resulting in ash, flue gas, and heat, while pyrolysis thermally decomposes organic materials in an oxygen-free environment to produce bio-oil, syngas, and char. Pyrolysis offers environmental advantages by reducing harmful emissions and enabling energy recovery from waste plastics and biomass more efficiently than traditional incineration. Choosing between these technologies depends on waste composition, desired energy recovery, and emission control requirements.

Table of Comparison

| Aspect | Incineration | Pyrolysis |

|---|---|---|

| Process | Combustion of waste in presence of oxygen | Thermal decomposition of waste in absence of oxygen |

| Temperature Range | 850degC to 1100degC | 300degC to 700degC |

| Emissions | Higher CO2 and harmful gases | Lower emissions, produces syngas and bio-oil |

| Energy Recovery | Generates electricity via steam turbines | Produces syngas usable for fuel or power |

| Residue | Bottom ash and fly ash requiring disposal | Char residue with potential value |

| Environmental Impact | Potential air pollution, requires strict controls | Lower environmental footprint, more sustainable |

| Waste Types | Suitable for mixed municipal solid waste | Best for plastics, tires, biomass |

Introduction to Waste Management Technologies

Incineration and pyrolysis are prominent waste management technologies designed to reduce volume and recover energy from waste materials. Incineration involves the combustion of waste at high temperatures, converting organic matter into ash, flue gas, and heat, effectively reducing landfill dependency. Pyrolysis thermally decomposes waste in an oxygen-free environment, producing syngas, bio-oil, and char, offering a more controlled process with potential for higher resource recovery and lower emissions.

Defining Incineration and Pyrolysis

Incineration is a high-temperature waste treatment process that combusts organic materials, converting them into ash, flue gas, and heat. Pyrolysis thermally decomposes organic waste in an oxygen-free environment, producing char, oil, and syngas without combustion. Both technologies serve as alternatives for reducing waste volume and recovering energy, but they differ fundamentally in process conditions and by-products.

How Incineration Works

Incineration works by combusting waste materials at high temperatures, typically between 850degC and 1100degC, converting organic substances into ash, flue gas, and heat energy. This process reduces waste volume by up to 90% and generates electricity or steam through heat recovery systems. Emission control technologies such as scrubbers and filters are implemented to minimize the release of pollutants like dioxins and particulate matter.

How Pyrolysis Works

Pyrolysis decomposes organic waste through thermal degradation in an oxygen-free environment, producing bio-oil, syngas, and char. The process involves heating materials to temperatures between 300degC and 900degC, breaking chemical bonds without combustion. This method reduces landfill volume and allows energy recovery with lower emissions compared to incineration.

Environmental Impacts: Incineration vs Pyrolysis

Incineration releases significant amounts of carbon dioxide, dioxins, and heavy metals, contributing to air pollution and greenhouse gas emissions, whereas pyrolysis produces fewer harmful emissions by operating in an oxygen-starved environment. Pyrolysis generates syngas and bio-oil that can be recycled as energy sources, reducing landfill use and minimizing environmental footprint. Both methods help reduce waste volume, but pyrolysis offers a cleaner alternative with lower toxic residue and better potential for resource recovery.

Energy Recovery and Efficiency Comparison

Incineration and pyrolysis both recover energy from waste, but incineration typically converts waste into heat and electricity through combustion, achieving energy efficiency rates around 20-30%. Pyrolysis operates at lower temperatures in an oxygen-free environment, producing syngas, bio-oil, and char with potential for higher energy recovery efficiency, sometimes exceeding 30-40% when integrated with combined heat and power systems. Pyrolysis offers more versatile fuel products and lower emissions, while incineration provides more immediate and continuous energy generation.

Emissions and Pollution Control

Incineration releases high levels of dioxins, furans, and particulate matter, necessitating advanced flue gas treatment systems to minimize air pollution. Pyrolysis operates at lower temperatures in an oxygen-deficient environment, producing fewer toxic emissions and enabling easier capture of volatile organic compounds and tar residues. Enhanced pollution control technologies in pyrolysis plants contribute to reduced greenhouse gas emissions compared to traditional incineration.

Cost Analysis: Incineration vs Pyrolysis

Incineration typically incurs higher operational and maintenance costs due to the need for advanced emission control systems and extensive regulatory compliance. Pyrolysis often presents lower processing expenses and potential revenue from byproducts such as bio-oil and syngas, enhancing its cost-efficiency. Capital investment for pyrolysis facilities varies widely but can be more scalable compared to the large, complex infrastructure required for incineration plants.

Regulatory and Policy Considerations

Regulatory frameworks for waste management strictly monitor incineration due to emission concerns, enforcing limits on pollutants like dioxins and heavy metals under standards such as the EPA's Clean Air Act. Pyrolysis faces less comprehensive regulations but is increasingly subject to policies addressing byproduct handling and energy recovery efficiency to ensure environmental safety. Both technologies require permits and compliance with local and international waste disposal policies, emphasizing the importance of stringent monitoring to minimize ecological impact.

Future Trends in Waste Treatment Technologies

Incineration technology is evolving to incorporate advanced emission control systems that significantly reduce toxic pollutants and improve energy recovery efficiency. Pyrolysis is gaining traction as a sustainable alternative, offering the ability to convert diverse waste streams into valuable fuels and chemicals with lower greenhouse gas emissions. Future trends emphasize integrating digital monitoring and AI optimization to enhance process efficiency and environmental compliance in both technologies.

Related Important Terms

Advanced Thermal Treatment (ATT)

Advanced Thermal Treatment (ATT) methods like incineration and pyrolysis efficiently reduce municipal solid waste volume while recovering energy; incineration combusts waste at high temperatures producing heat and electricity with emissions control, whereas pyrolysis thermally decomposes organic waste in an oxygen-limited environment creating syngas, bio-oil, and char with lower pollutant output. Both technologies play crucial roles in sustainable waste management by minimizing landfill dependency and enabling resource recovery, yet pyrolysis offers enhanced environmental benefits through reduced greenhouse gas emissions and greater feedstock versatility.

Autothermal Pyrolysis

Autothermal pyrolysis optimizes waste-to-energy conversion by sustaining the necessary heat through internal exothermic reactions, reducing external energy input compared to traditional incineration. This process enhances energy efficiency and minimizes harmful emissions by decomposing waste in an oxygen-limited environment, producing valuable syngas and char as byproducts.

Refuse-Derived Fuel Incineration (RDF Incineration)

Refuse-Derived Fuel Incineration (RDF Incineration) efficiently converts waste into energy by combusting processed refuse with high calorific value, reducing landfill volume and generating electricity. Unlike pyrolysis that thermally decomposes waste in an oxygen-free environment producing syngas and char, RDF incineration offers continuous energy recovery with lower operational complexity and established emission control technologies.

Syngas Upgrading

Syngas upgrading in incineration involves cleaning and conditioning the gas to remove impurities like tar, sulfur compounds, and particulates to improve its combustion efficiency and reduce emissions. In pyrolysis, syngas upgrading focuses on enhancing gas quality by removing contaminants and adjusting the chemical composition to maximize hydrogen and carbon monoxide content for use in energy generation or chemical synthesis.

Ash Melting Point Optimization

Optimizing the ash melting point during incineration prevents slagging and fouling, enhancing operational efficiency and reducing maintenance costs. Pyrolysis, with lower combustion temperatures, produces char with higher melting points, minimizing ash-related issues and improving residue stability for potential reuse.

Fluidized Bed Incinerator

Fluidized bed incinerators offer efficient waste treatment by providing uniform temperature distribution and enhanced gas-solid contact, resulting in complete combustion with reduced emissions compared to pyrolysis. Unlike pyrolysis, which decomposes waste in oxygen-limited environments to produce syngas and char, fluidized bed incineration ensures rapid oxidation of waste materials, minimizing toxic byproducts and optimizing energy recovery.

Slow Pyrolysis Reactor

Slow pyrolysis reactors convert waste into biochar, syngas, and bio-oil through thermal decomposition at moderate temperatures in an oxygen-limited environment, enhancing carbon capture compared to incineration, which burns waste completely producing primarily ash, CO2, and harmful emissions. This controlled process in slow pyrolysis improves energy recovery efficiency and reduces greenhouse gas emissions, making it a sustainable alternative to traditional incineration for organic waste management.

Biochar Valorization

Incineration converts waste into energy by complete combustion, producing ash with limited value, whereas pyrolysis thermally decomposes organic waste in an oxygen-limited environment, generating biochar rich in carbon content. Biochar valorization enhances soil fertility and carbon sequestration, offering a sustainable waste management approach superior to traditional incineration by enabling resource recovery and environmental benefits.

Emission Scrubbing Technologies

Incineration emission scrubbing technologies typically utilize wet scrubbers and electrostatic precipitators to reduce particulate matter, sulfur oxides, and acidic gases, achieving removal efficiencies often exceeding 90%. Pyrolysis emission control relies on advanced catalytic converters and activated carbon filters to capture volatile organic compounds and heavy metals, minimizing dioxin formation and greenhouse gas emissions during thermal decomposition.

Waste-to-Hydrogen Pyrolysis

Waste-to-hydrogen pyrolysis converts organic waste into hydrogen gas and valuable byproducts through thermal decomposition in an oxygen-free environment, offering a cleaner alternative to incineration which combusts waste and emits harmful pollutants. Pyrolysis enhances hydrogen yield while minimizing greenhouse gases and toxic emissions, supporting sustainable energy production and waste management strategies.

Incineration vs Pyrolysis Infographic

industrydif.com

industrydif.com