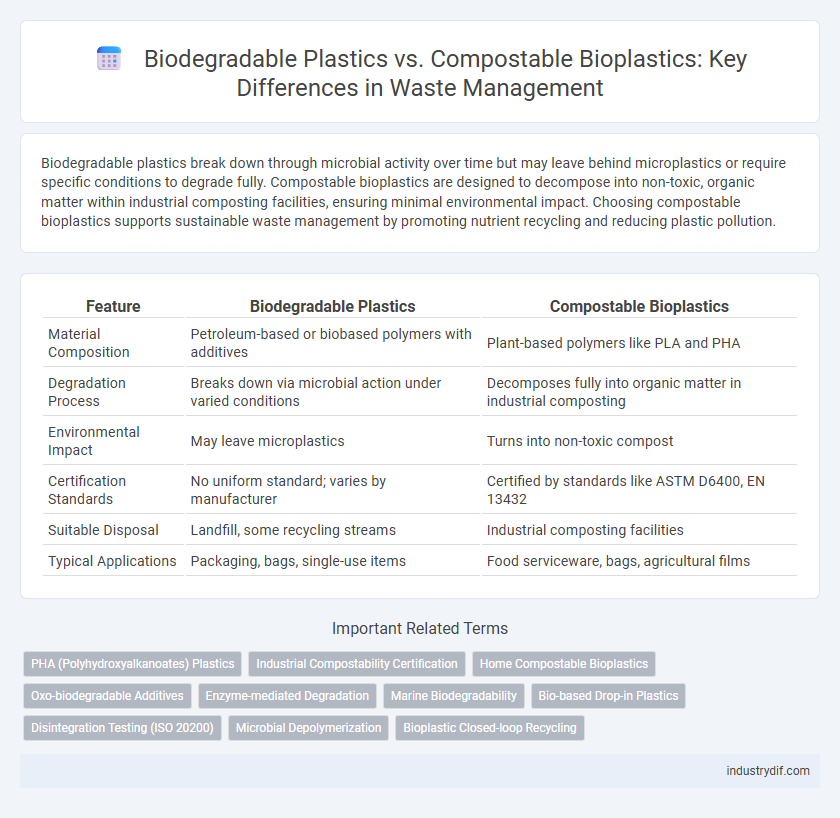

Biodegradable plastics break down through microbial activity over time but may leave behind microplastics or require specific conditions to degrade fully. Compostable bioplastics are designed to decompose into non-toxic, organic matter within industrial composting facilities, ensuring minimal environmental impact. Choosing compostable bioplastics supports sustainable waste management by promoting nutrient recycling and reducing plastic pollution.

Table of Comparison

| Feature | Biodegradable Plastics | Compostable Bioplastics |

|---|---|---|

| Material Composition | Petroleum-based or biobased polymers with additives | Plant-based polymers like PLA and PHA |

| Degradation Process | Breaks down via microbial action under varied conditions | Decomposes fully into organic matter in industrial composting |

| Environmental Impact | May leave microplastics | Turns into non-toxic compost |

| Certification Standards | No uniform standard; varies by manufacturer | Certified by standards like ASTM D6400, EN 13432 |

| Suitable Disposal | Landfill, some recycling streams | Industrial composting facilities |

| Typical Applications | Packaging, bags, single-use items | Food serviceware, bags, agricultural films |

Defining Biodegradable Plastics in Modern Waste Management

Biodegradable plastics are materials engineered to break down into natural substances like water, carbon dioxide, and biomass through microbial action within a specific timeframe, often under controlled environmental conditions. These plastics contribute to modern waste management by reducing landfill accumulation and decreasing reliance on fossil fuels compared to traditional plastics. However, biodegradability varies significantly based on polymer composition, environmental factors, and waste processing infrastructure.

Understanding Compostable Bioplastics: Key Characteristics

Compostable bioplastics are a subset of biodegradable plastics designed to break down into non-toxic components within a specific timeframe under industrial composting conditions, typically 90 to 180 days. These materials, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), must meet strict ASTM D6400 or EN 13432 standards to ensure complete disintegration and no harmful residues. Unlike general biodegradable plastics, compostable bioplastics contribute to sustainable waste management by supporting nutrient recovery and reducing landfill impact when properly processed.

Chemical Composition: Biodegradable vs Compostable Materials

Biodegradable plastics typically consist of polymers like polybutylene adipate terephthalate (PBAT) and polylactic acid (PLA), which break down through microbial activity over varying timeframes under natural conditions. Compostable bioplastics are specifically formulated with additives and natural polymers such as starch or cellulose to meet standardized criteria like ASTM D6400 for complete decomposition within industrial composting facilities. The chemical composition of compostable bioplastics ensures rapid hydrolysis and microbial assimilation, distinguishing them from general biodegradable plastics that may persist longer in the environment due to less controlled degradation pathways.

Degradation Processes: How Each Plastic Breaks Down

Biodegradable plastics break down through microbial activity in various environments, often requiring industrial composting conditions to degrade efficiently, but their degradation time can vary widely depending on temperature, moisture, and oxygen levels. Compostable bioplastics undergo a more controlled and faster decomposition process within industrial composting facilities, converting into carbon dioxide, water, and organic matter without leaving toxic residues. Understanding the specific degradation mechanisms and environmental requirements is essential for optimizing waste management and minimizing plastic pollution.

Industrial vs Home Composting: Infrastructure Requirements

Biodegradable plastics often require industrial composting facilities operating at high temperatures and controlled conditions to break down effectively, limiting their disposal options. Compostable bioplastics are specifically designed to decompose under both industrial and home composting environments, though home composting may take longer due to lower temperatures and variable conditions. Waste management infrastructure that supports industrial composting enhances the efficiency of biodegradable plastic processing, while expanding home composting practices improves overall organic waste diversion.

Environmental Impact: Waste Reduction and Pollution Prevention

Biodegradable plastics break down more quickly than conventional plastics, reducing landfill volume and minimizing long-term environmental pollution. Compostable bioplastics not only degrade but also convert into nutrient-rich compost, enhancing soil health and reducing chemical waste. Both materials significantly lower microplastic pollution, but compostable bioplastics offer superior benefits in waste reduction and ecosystem restoration through organic matter recycling.

Certification Standards: Labels and Regulatory Guidelines

Certification standards for biodegradable plastics include ASTM D6400 and ISO 17088, which verify materials break down under specific environmental conditions but do not guarantee compostability. Compostable bioplastics must meet stricter criteria under standards like EN 13432 and BPI certification, ensuring complete biodegradation and safety in industrial composting facilities. Regulatory guidelines distinguish these products by labeling requirements to inform consumers about proper disposal methods and environmental impact compliance.

Common Misconceptions about Biodegradable and Compostable Plastics

Biodegradable plastics often require specific environmental conditions and extended timeframes to break down, contrary to the common belief that they decompose quickly in any setting. Compostable bioplastics must meet standardized criteria, such as ASTM D6400 or EN 13432, to ensure they break down into non-toxic components within industrial composting facilities. Misunderstanding these distinctions leads to improper disposal practices, hindering waste management and environmental benefits.

End-of-Life Scenarios: Recycling, Landfill, and Compost Facilities

Biodegradable plastics often degrade poorly in landfills due to limited oxygen, resulting in methane emissions, whereas compostable bioplastics break down efficiently in industrial compost facilities under specific temperature and humidity conditions. Recycling streams for biodegradable plastics are limited, causing contamination issues in conventional plastic recycling systems, while compostable bioplastics require dedicated composting infrastructure to prevent landfill diversion. Proper sorting and end-of-life management are crucial to maximize environmental benefits and reduce the negative impact of both materials in waste treatment processes.

Choosing the Right Material for Sustainable Packaging

Biodegradable plastics break down through microbial activity but may leave harmful residues, while compostable bioplastics fully decompose into non-toxic components under industrial composting conditions. Selecting sustainable packaging requires evaluating end-of-life options and ensuring materials align with local waste management infrastructures to prevent contamination and maximize environmental benefits. Prioritizing certified compostable bioplastics supports circular economy goals by reducing landfill waste and promoting organic waste recycling.

Related Important Terms

PHA (Polyhydroxyalkanoates) Plastics

PHA (Polyhydroxyalkanoates) plastics are biodegradable bioplastics produced by microbial fermentation of renewable resources, offering a sustainable alternative to conventional plastics due to their ability to fully decompose in marine and soil environments without toxic residues. Unlike some compostable bioplastics that require industrial composting conditions, PHA plastics naturally biodegrade in diverse ecosystems, making them a crucial innovation in reducing plastic pollution and advancing circular economy goals.

Industrial Compostability Certification

Industrial compostability certification ensures that compostable bioplastics meet strict standards for accelerated biodegradation in controlled environments, unlike many biodegradable plastics lacking such verification. Certifications like ASTM D6400 and EN 13432 guarantee materials break down safely without harming ecosystems, promoting effective waste management and reducing landfill impact.

Home Compostable Bioplastics

Home compostable bioplastics are engineered to break down efficiently in domestic composting environments, unlike some biodegradable plastics that require industrial composting facilities for proper degradation. These bioplastics typically consist of materials like polylactic acid (PLA) or polyhydroxyalkanoates (PHA), which decompose into non-toxic components within 90 days under home composting conditions, reducing waste accumulation and supporting sustainable soil health.

Oxo-biodegradable Additives

Oxo-biodegradable additives are often added to conventional plastics to accelerate fragmentation, but they do not ensure full biodegradation or compostability, unlike compostable bioplastics that break down completely into non-toxic residues under industrial composting conditions. These additives can lead to microplastic pollution, undermining environmental benefits promoted by biodegradable or compostable materials in waste management systems.

Enzyme-mediated Degradation

Enzyme-mediated degradation in biodegradable plastics involves specific enzymes breaking down polymer chains into smaller molecules, facilitating environmental assimilation without toxic residues. Compostable bioplastics require particular enzymatic activities under controlled composting conditions, ensuring complete disintegration into carbon dioxide, water, and biomass within a defined timeframe.

Marine Biodegradability

Marine biodegradability distinguishes compostable bioplastics, which break down efficiently in aquatic environments within months, from conventional biodegradable plastics that often persist and fragment into harmful microplastics in marine ecosystems. Certification standards such as ASTM D6691 and ISO 14851 validate marine biodegradability by measuring the rate of organic carbon conversion and ensuring minimal ecological impact in seawater conditions.

Bio-based Drop-in Plastics

Bio-based drop-in plastics, derived from renewable resources yet chemically identical to conventional plastics, offer a sustainable alternative by integrating seamlessly into existing recycling and waste management systems. Unlike compostable bioplastics that require industrial composting conditions for degradation, bio-based drop-in plastics prioritize reducing fossil fuel dependence while maintaining durability and compatibility within current infrastructure.

Disintegration Testing (ISO 20200)

Disintegration testing according to ISO 20200 evaluates the breakdown of biodegradable plastics and compostable bioplastics under controlled composting conditions, measuring the physical disintegration into fragments smaller than 2 mm within a defined timeframe. Biodegradable plastics may partially disintegrate but do not always meet compostability criteria, whereas compostable bioplastics are designed to fully disintegrate and mineralize, confirming compliance with ISO standards for effective waste management and environmental sustainability.

Microbial Depolymerization

Biodegradable plastics undergo microbial depolymerization through enzymatic action that breaks down polymers into smaller molecules, but the process can be incomplete and vary widely depending on environmental conditions. Compostable bioplastics are specifically designed to fully biodegrade via microbial depolymerization within controlled composting environments, ensuring efficient conversion into biomass, CO2, and water without toxic residues.

Bioplastic Closed-loop Recycling

Bioplastic closed-loop recycling enables the recovery and reuse of materials in biodegradable plastics, reducing landfill waste and decreasing environmental impact by maintaining material value within the production cycle. Compostable bioplastics, designed to break down into non-toxic components in industrial composting facilities, complement closed-loop recycling by ensuring end-of-life disposal returns nutrients to the soil, supporting sustainable waste management.

Biodegradable Plastics vs Compostable Bioplastics Infographic

industrydif.com

industrydif.com