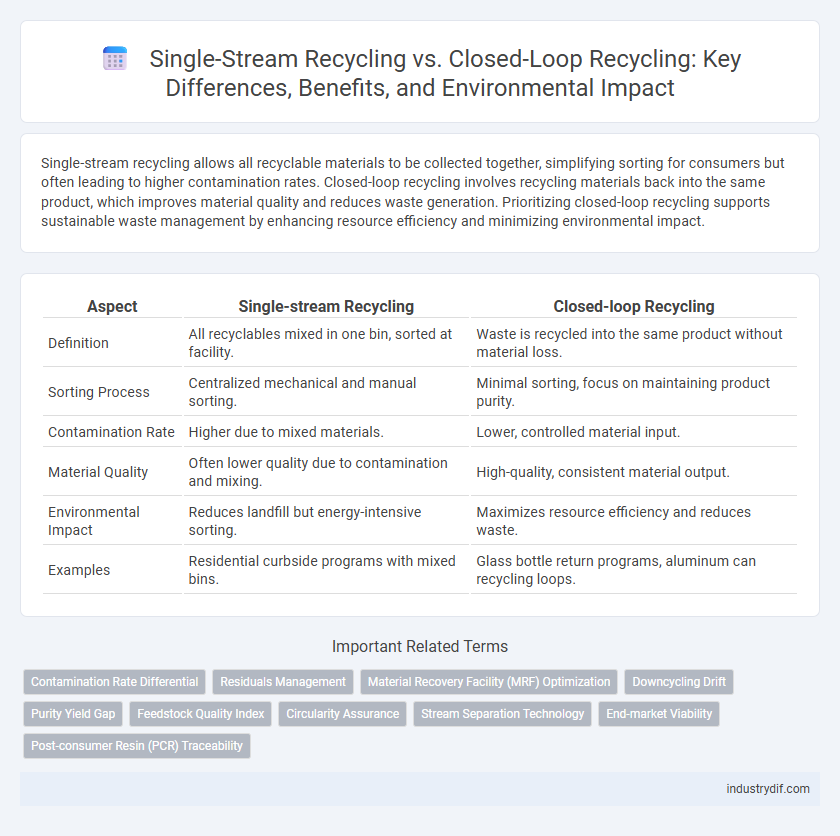

Single-stream recycling allows all recyclable materials to be collected together, simplifying sorting for consumers but often leading to higher contamination rates. Closed-loop recycling involves recycling materials back into the same product, which improves material quality and reduces waste generation. Prioritizing closed-loop recycling supports sustainable waste management by enhancing resource efficiency and minimizing environmental impact.

Table of Comparison

| Aspect | Single-stream Recycling | Closed-loop Recycling |

|---|---|---|

| Definition | All recyclables mixed in one bin, sorted at facility. | Waste is recycled into the same product without material loss. |

| Sorting Process | Centralized mechanical and manual sorting. | Minimal sorting, focus on maintaining product purity. |

| Contamination Rate | Higher due to mixed materials. | Lower, controlled material input. |

| Material Quality | Often lower quality due to contamination and mixing. | High-quality, consistent material output. |

| Environmental Impact | Reduces landfill but energy-intensive sorting. | Maximizes resource efficiency and reduces waste. |

| Examples | Residential curbside programs with mixed bins. | Glass bottle return programs, aluminum can recycling loops. |

Introduction to Single-stream and Closed-loop Recycling

Single-stream recycling simplifies waste sorting by allowing all recyclables like paper, plastics, and metals to be collected in a single bin, increasing participation rates but often causing higher contamination levels. Closed-loop recycling involves recycling materials back into the same product, such as turning used aluminum cans into new cans, enhancing material quality and reducing resource consumption. Both systems aim to improve recycling efficiency, but closed-loop recycling prioritizes maintaining material integrity for sustainable manufacturing.

Key Differences Between Single-stream and Closed-loop Recycling

Single-stream recycling allows all recyclables to be collected in one bin, simplifying collection but often resulting in higher contamination rates and lower material quality. Closed-loop recycling involves recycling materials back into the same product type, maintaining material purity and reducing the need for virgin resources. This closed system enhances sustainability by minimizing waste and improving the efficiency of resource recovery.

How Single-stream Recycling Works

Single-stream recycling allows consumers to place all recyclables, such as paper, plastics, metals, and glass, in a single bin, simplifying collection and increasing participation rates. Materials are transported to a Materials Recovery Facility (MRF) where advanced sorting technologies like optical sorters, magnets, and air classifiers separate and process items for resale or reuse. This streamlined approach reduces contamination risks in comparison to multi-stream systems but requires efficient sorting to maintain material quality for recycling markets.

How Closed-loop Recycling Works

Closed-loop recycling involves collecting and processing waste materials to create new products of the same type, maintaining material quality and reducing the need for virgin resources. This process typically uses advanced sorting and purification technologies to transform post-consumer products, such as paper or plastics, back into raw materials for manufacturing identical goods. By minimizing contamination and degradation, closed-loop systems enhance sustainability and promote a circular economy in waste management.

Advantages of Single-stream Recycling

Single-stream recycling significantly increases participation rates by allowing consumers to place all recyclables into a single bin without sorting, which simplifies the process and boosts collection volumes. It reduces the need for multiple curbside bins, lowering municipal collection costs and enhancing operational efficiency. The convenience of single-stream systems encourages higher overall recycling rates, contributing to increased diversion of waste from landfills.

Limitations of Single-stream Recycling

Single-stream recycling faces limitations such as increased contamination rates due to the mixing of materials, which reduces the quality of recyclable outputs. Equipment and sorting costs rise as facilities must implement advanced technology to separate diverse recyclables effectively. Contaminants in single-stream recycling can lead to higher rejection rates and limit the ability to produce high-grade recycled materials, undermining overall efficiency.

Benefits of Closed-loop Recycling

Closed-loop recycling enhances material sustainability by continuously reprocessing waste into the same product, reducing the need for virgin resources and minimizing environmental impact. This system improves product quality and reduces contamination compared to single-stream recycling, leading to higher recycling rates and economic efficiency. Businesses benefit from closed-loop recycling through reduced raw material costs and strengthened corporate social responsibility initiatives.

Challenges of Implementing Closed-loop Recycling

Implementing closed-loop recycling faces significant challenges such as high contamination rates that reduce material quality and hinder the recycling process. Infrastructure limitations and the need for advanced sorting technologies increase operational costs and complexity. Furthermore, establishing consistent market demand for recycled materials remains difficult, impacting the economic feasibility of closed-loop systems.

Environmental Impact: Single-stream vs Closed-loop Recycling

Single-stream recycling simplifies waste sorting by combining all recyclables into one bin, increasing collection rates but often resulting in higher contamination and reduced material quality. Closed-loop recycling maintains the integrity of materials by continuously processing products back into the same or similar items, significantly lowering greenhouse gas emissions and resource extraction. Studies reveal closed-loop systems reduce energy consumption by up to 70% compared to single-stream methods, making them more effective in minimizing environmental impact.

Choosing the Right Recycling System for Your Industry

Single-stream recycling simplifies waste sorting by combining all recyclables into one bin, increasing participation rates in industries with diverse waste streams but often leads to higher contamination and lower material quality. Closed-loop recycling maintains material purity by keeping waste streams separate, ideal for manufacturing sectors requiring high-grade recycled inputs for product consistency and sustainability goals. Selecting the appropriate recycling system depends on balancing operational efficiency, material quality requirements, and environmental impact specific to the industry's waste composition and end-use applications.

Related Important Terms

Contamination Rate Differential

Single-stream recycling systems often exhibit higher contamination rates, sometimes exceeding 25%, due to the commingling of materials, which complicates sorting and reduces overall material quality. Closed-loop recycling, by contrast, maintains separate material streams, resulting in contamination rates as low as 5%, thereby enhancing efficiency and producing higher-purity recycled outputs.

Residuals Management

Single-stream recycling streamlines collection by combining all recyclables, but often increases residual waste due to contamination, complicating residuals management efforts. Closed-loop recycling minimizes residuals through source-separated streams, enhancing material quality and reducing contamination for more efficient residuals processing.

Material Recovery Facility (MRF) Optimization

Single-stream recycling improves Material Recovery Facility (MRF) efficiency by allowing all recyclables to be collected together, reducing sorting complexity but increasing contamination rates, whereas closed-loop recycling minimizes contamination by keeping materials separated from collection through processing, enhancing overall material quality. Optimizing MRF operations involves balancing throughput speed, sorting technology advancements such as optical sorters and AI-driven robotics, and contamination management to maximize recyclables' recovery rates and market value.

Downcycling Drift

Single-stream recycling combines all recyclables into one collection stream, often causing downcycling drift where materials degrade in quality due to contamination and mixed sorting. Closed-loop recycling maintains product quality by recycling materials into the same product type, minimizing downcycling and preserving material value.

Purity Yield Gap

Single-stream recycling often results in lower purity yield due to material contamination, which reduces the quality and value of recovered recyclables compared to closed-loop recycling processes. Closed-loop recycling maintains higher purity by directly reprocessing materials into the same product, minimizing contamination and maximizing resource efficiency.

Feedstock Quality Index

Single-stream recycling often results in lower Feedstock Quality Index due to contamination from mixed recyclables, negatively impacting material purity and processing efficiency. Closed-loop recycling maintains a higher Feedstock Quality Index by preserving material integrity, enabling better recovery rates and consistent production of high-quality recycled goods.

Circularity Assurance

Single-stream recycling simplifies collection by combining all recyclables but often leads to contamination, reducing material quality and circularity assurance. Closed-loop recycling enhances circularity by processing specific materials into high-quality products, ensuring consistent reuse and minimizing waste leakage.

Stream Separation Technology

Single-stream recycling utilizes stream separation technology to sort mixed recyclables such as paper, plastics, and metals into distinct material categories, enhancing processing efficiency at material recovery facilities (MRFs). Closed-loop recycling focuses on capturing and reprocessing specific waste streams, like PET plastics, maintaining material purity and quality for direct reuse in manufacturing new products.

End-market Viability

Single-stream recycling offers increased convenience but often results in higher contamination rates, reducing the quality and marketability of recovered materials. Closed-loop recycling ensures higher purity and consistent material quality, enhancing end-market viability and supporting sustainable manufacturing processes.

Post-consumer Resin (PCR) Traceability

Single-stream recycling challenges Post-consumer Resin (PCR) traceability due to the commingling of various materials, complicating accurate identification and quality control. Closed-loop recycling enhances PCR traceability by maintaining material segregation throughout the process, ensuring higher purity and reliable tracking from collection to product remanufacturing.

Single-stream Recycling vs Closed-loop Recycling Infographic

industrydif.com

industrydif.com