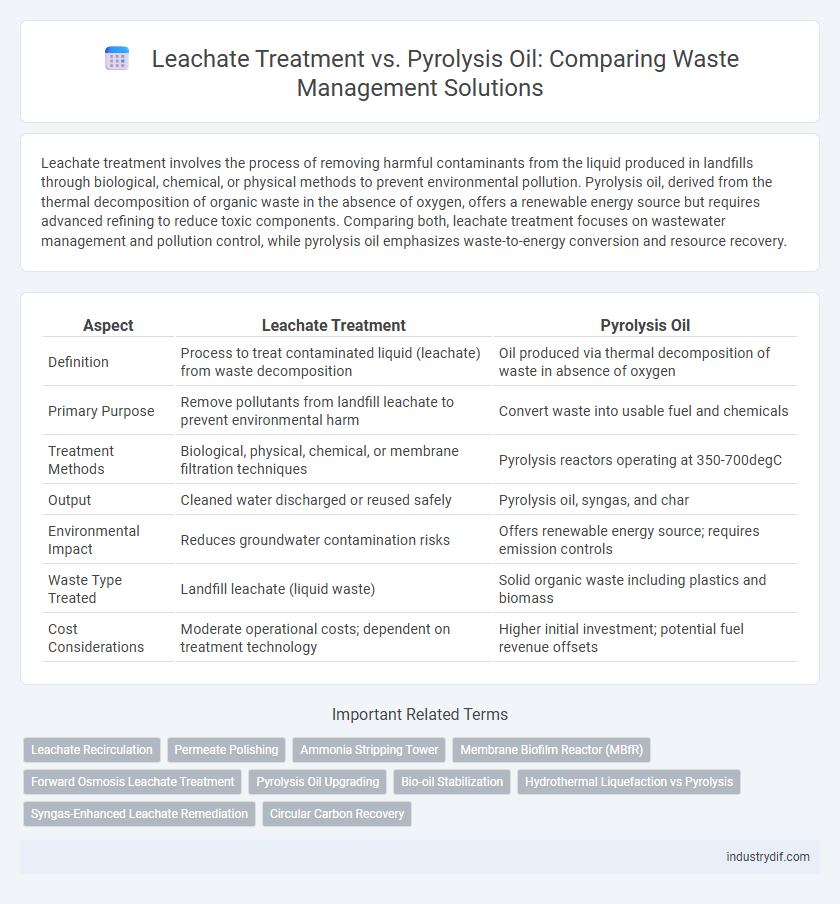

Leachate treatment involves the process of removing harmful contaminants from the liquid produced in landfills through biological, chemical, or physical methods to prevent environmental pollution. Pyrolysis oil, derived from the thermal decomposition of organic waste in the absence of oxygen, offers a renewable energy source but requires advanced refining to reduce toxic components. Comparing both, leachate treatment focuses on wastewater management and pollution control, while pyrolysis oil emphasizes waste-to-energy conversion and resource recovery.

Table of Comparison

| Aspect | Leachate Treatment | Pyrolysis Oil |

|---|---|---|

| Definition | Process to treat contaminated liquid (leachate) from waste decomposition | Oil produced via thermal decomposition of waste in absence of oxygen |

| Primary Purpose | Remove pollutants from landfill leachate to prevent environmental harm | Convert waste into usable fuel and chemicals |

| Treatment Methods | Biological, physical, chemical, or membrane filtration techniques | Pyrolysis reactors operating at 350-700degC |

| Output | Cleaned water discharged or reused safely | Pyrolysis oil, syngas, and char |

| Environmental Impact | Reduces groundwater contamination risks | Offers renewable energy source; requires emission controls |

| Waste Type Treated | Landfill leachate (liquid waste) | Solid organic waste including plastics and biomass |

| Cost Considerations | Moderate operational costs; dependent on treatment technology | Higher initial investment; potential fuel revenue offsets |

Overview of Leachate Treatment and Pyrolysis Oil Processes

Leachate treatment involves the removal of contaminants from liquid that percolates through waste in landfills, primarily using biological, chemical, and physical methods to prevent environmental pollution. Pyrolysis oil production converts waste materials through thermal decomposition in an oxygen-limited environment, generating a liquid fuel that can be used as an alternative energy source. Both processes aim to mitigate waste impact, with leachate treatment focusing on pollution control and pyrolysis oil on energy recovery.

Key Differences: Leachate Treatment vs Pyrolysis Oil

Leachate treatment involves processes like biological, chemical, or physical methods to remove contaminants from landfill leachate, ensuring environmental safety and regulatory compliance. Pyrolysis oil is a product derived from the thermal decomposition of organic waste in an oxygen-limited environment, offering a renewable fuel source with a high energy content. Key differences include the objective--leachate treatment aims to mitigate pollution, whereas pyrolysis oil production focuses on waste-to-energy conversion--and the nature of outputs, with treated leachate being purified water and byproducts, compared to combustible liquid fuel from pyrolysis.

Technologies Used in Leachate Treatment

Leachate treatment technologies primarily include biological processes such as activated sludge and membrane bioreactors, physico-chemical methods like coagulation-flocculation and advanced oxidation, and physical treatments including reverse osmosis and ultrafiltration. Emerging technologies focus on integrating nanofiltration membranes and constructed wetlands to enhance contaminant removal efficiency and reduce environmental impact. These processes target the reduction of organic pollutants, heavy metals, and ammonia to meet regulatory discharge standards and protect groundwater quality.

Pyrolysis Oil Production: Methods and Applications

Pyrolysis oil production involves the thermal decomposition of organic waste materials at high temperatures in the absence of oxygen, generating a liquid bio-oil rich in energy content. Methods such as fast pyrolysis optimize yield and quality by rapidly heating biomass to 450-600degC, producing bio-oil used as fuel, chemical feedstock, or renewable energy source. Applications of pyrolysis oil include power generation, industrial heating, and as a sustainable alternative to fossil fuels, reducing landfill waste and mitigating environmental pollution.

Environmental Impact: Leachate Management vs Pyrolysis Conversion

Leachate treatment focuses on preventing soil and groundwater contamination by effectively removing hazardous chemicals and heavy metals from landfill leachate, ensuring compliance with environmental regulations. Pyrolysis oil production converts waste into bio-oil, reducing landfill volumes and generating renewable energy, but it may release toxic emissions if not properly managed. Comparing both, leachate management mitigates pollution directly linked to waste decomposition, whereas pyrolysis conversion offers a waste-to-energy solution with a distinct emission profile requiring advanced control technologies.

Efficiency and Resource Recovery Comparison

Leachate treatment efficiently removes contaminants through biological and chemical processes, achieving high pollutant degradation rates and recovering water for reuse. Pyrolysis oil production converts waste into valuable liquid fuel, maximizing resource recovery by transforming organic matter into energy-dense compounds. While leachate treatment prioritizes environmental protection and water reclamation, pyrolysis oil focuses on energy recovery and waste valorization, offering complementary benefits in waste management.

Cost Analysis: Leachate Treatment vs Pyrolysis Oil

Leachate treatment typically incurs higher operational costs due to complex wastewater management and stringent environmental regulations, averaging $0.50 to $1.50 per gallon treated. Pyrolysis oil production, while capital-intensive upfront with reactor installation costs ranging from $500,000 to $2 million, offers lower ongoing expenses and potential revenue streams from bio-oil sales, reducing overall cost per unit. Comparing lifecycle costs reveals pyrolysis oil can be more economically sustainable by converting waste into valuable fuel, whereas leachate treatment primarily addresses environmental compliance without direct profit generation.

Regulatory Considerations for Waste Processing

Regulatory considerations for waste processing require stringent compliance with environmental standards governing leachate treatment and pyrolysis oil production, including limits on hazardous substances and emissions. Leachate treatment must adhere to wastewater discharge permits and landfill regulations, ensuring contaminants like heavy metals and organic compounds meet legal thresholds. Pyrolysis oil production is regulated under waste-to-energy and chemical handling frameworks, demanding certification for pollutant control and safe fuel use to minimize environmental impact.

Sustainability Benefits of Pyrolysis Oil

Pyrolysis oil offers significant sustainability benefits over traditional leachate treatment by converting waste into valuable fuel, reducing landfill volume and greenhouse gas emissions. This process enables energy recovery from organic waste, promoting a circular economy and decreasing dependence on fossil fuels. Pyrolysis oil production also minimizes toxic byproducts and leachate contamination, enhancing overall environmental protection.

Future Trends in Waste Management Technologies

Emerging waste management technologies emphasize advanced leachate treatment methods utilizing membrane bioreactors and advanced oxidation processes to enhance contaminant removal efficiency and reduce environmental impact. Pyrolysis oil, derived from thermal decomposition of waste, is gaining traction as a sustainable alternative fuel, with innovations focusing on improving yield quality and integrating carbon capture technologies. Future trends indicate a convergence of chemical recycling techniques and digital monitoring systems to optimize resource recovery and minimize hazardous outputs in waste treatment.

Related Important Terms

Leachate Recirculation

Leachate recirculation enhances the efficiency of leachate treatment by promoting microbial degradation and reducing pollutant concentrations in landfill waste management. Unlike pyrolysis oil, which involves converting waste into synthetic fuel through thermal decomposition, leachate recirculation optimizes landfill biodegradation processes and minimizes environmental contamination risk.

Permeate Polishing

Permeate polishing in leachate treatment significantly enhances the removal of residual contaminants, improving water quality more effectively than pyrolysis oil processes, which primarily focus on solid waste conversion rather than liquid effluent purification. Advanced membrane filtration and adsorption techniques in permeate polishing offer superior reduction of organic compounds and heavy metals, crucial for meeting stringent environmental discharge standards.

Ammonia Stripping Tower

The ammonia stripping tower efficiently removes ammonia from landfill leachate, reducing toxicity and enabling safer discharge or further treatment, while pyrolysis oil production from waste focuses on converting organic material into valuable fuel, where ammonia content is typically managed during refining rather than initial processing. Optimizing leachate treatment with ammonia stripping towers minimizes environmental impact, whereas pyrolysis oil systems prioritize energy recovery and chemical byproduct control.

Membrane Biofilm Reactor (MBfR)

Membrane Biofilm Reactor (MBfR) technology enhances leachate treatment by efficiently removing contaminants like ammonia and nitrate through biofilm-mediated processes on membrane surfaces, offering a sustainable alternative to conventional methods. In contrast to pyrolysis oil production, MBfR focuses on water purification and nutrient removal, making it specifically suited for managing landfill leachate and reducing environmental pollution.

Forward Osmosis Leachate Treatment

Forward osmosis leachate treatment offers an energy-efficient solution for removing contaminants from landfill leachate by utilizing a semipermeable membrane to draw water across from a concentrated draw solution, resulting in high contaminant rejection and reduced fouling compared to conventional methods. Unlike pyrolysis oil production, which thermally decomposes waste into bio-oil, forward osmosis targets leachate purification and water recovery, emphasizing improved environmental compliance and resource sustainability in landfill management.

Pyrolysis Oil Upgrading

Pyrolysis oil upgrading enhances fuel quality by reducing oxygen content and improving stability, making it a sustainable alternative compared to traditional leachate treatment which primarily focuses on neutralizing harmful contaminants. Advanced upgrading techniques such as catalytic hydrotreatment and emulsification enable higher energy recovery and lower environmental impact, positioning pyrolysis oil as a promising solution in waste-to-energy conversion.

Bio-oil Stabilization

Leachate treatment techniques concentrate on extracting and neutralizing hazardous contaminants from landfill runoff, utilizing biological, chemical, or physical processes to minimize environmental impact. In contrast, pyrolysis oil stabilization focuses on converting biomass or waste materials into bio-oil, enhancing its chemical stability and energy content through catalytic upgrading or emulsification for efficient fuel applications.

Hydrothermal Liquefaction vs Pyrolysis

Hydrothermal liquefaction (HTL) efficiently converts wet waste into high-quality bio-crude oil by utilizing subcritical water conditions, resulting in lower energy consumption compared to pyrolysis, which requires dry feedstock and higher temperatures to produce pyrolysis oil. HTL offers enhanced nutrient recovery and reduced greenhouse gas emissions, making it a sustainable alternative for waste valorization over traditional pyrolysis processes.

Syngas-Enhanced Leachate Remediation

Syngas-enhanced leachate remediation leverages the combustion gases from pyrolysis oil processes to improve the biodegradation of contaminants in landfill leachate, increasing treatment efficiency and reducing toxic byproducts. This integration offers a sustainable approach by converting waste into energy while simultaneously optimizing leachate treatment through enhanced microbial activity driven by syngas components like hydrogen and carbon monoxide.

Circular Carbon Recovery

Leachate treatment captures and treats harmful contaminants from landfill runoff, preventing environmental pollution, while pyrolysis oil is produced through thermal decomposition of waste, enabling the recovery of circular carbon as a renewable energy source. Both methods contribute to circular carbon recovery by reducing landfill emissions and converting waste into valuable fuels, promoting sustainable waste management solutions.

Leachate Treatment vs Pyrolysis Oil Infographic

industrydif.com

industrydif.com