Refuse-derived fuel (RDF) converts non-recyclable waste into energy by processing materials like plastics and paper, reducing landfill use and generating power. Chemical recycling breaks down waste plastics into their molecular components, enabling the production of new plastics with minimal loss of quality. While RDF prioritizes energy recovery, chemical recycling emphasizes material recovery and sustainability in plastic waste management.

Table of Comparison

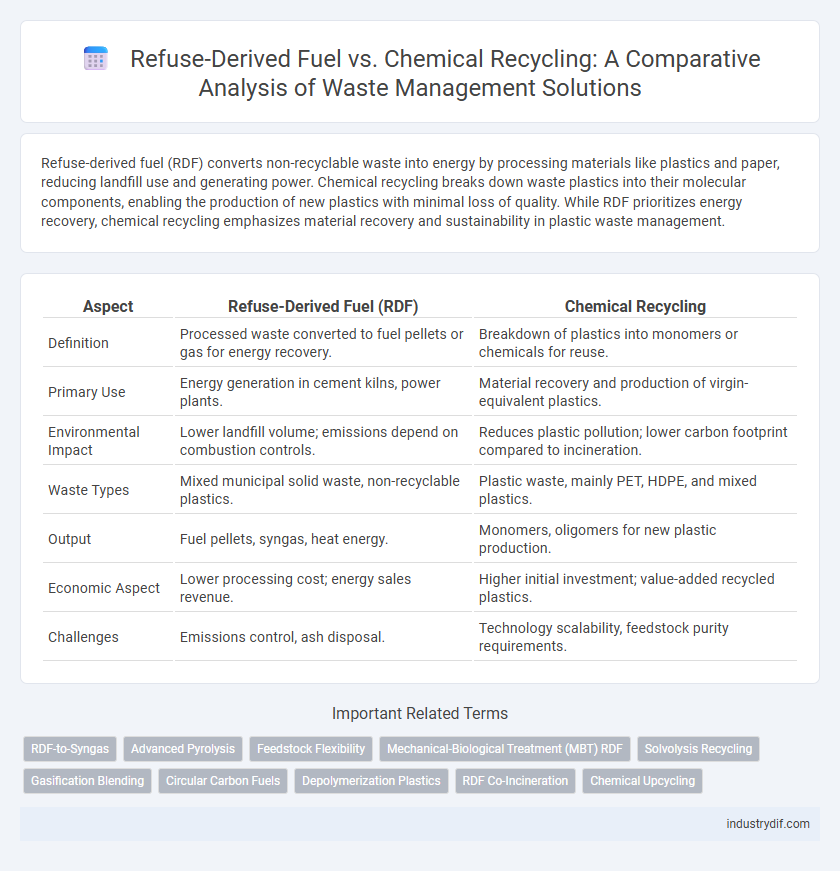

| Aspect | Refuse-Derived Fuel (RDF) | Chemical Recycling |

|---|---|---|

| Definition | Processed waste converted to fuel pellets or gas for energy recovery. | Breakdown of plastics into monomers or chemicals for reuse. |

| Primary Use | Energy generation in cement kilns, power plants. | Material recovery and production of virgin-equivalent plastics. |

| Environmental Impact | Lower landfill volume; emissions depend on combustion controls. | Reduces plastic pollution; lower carbon footprint compared to incineration. |

| Waste Types | Mixed municipal solid waste, non-recyclable plastics. | Plastic waste, mainly PET, HDPE, and mixed plastics. |

| Output | Fuel pellets, syngas, heat energy. | Monomers, oligomers for new plastic production. |

| Economic Aspect | Lower processing cost; energy sales revenue. | Higher initial investment; value-added recycled plastics. |

| Challenges | Emissions control, ash disposal. | Technology scalability, feedstock purity requirements. |

Overview of Refuse-Derived Fuel and Chemical Recycling

Refuse-Derived Fuel (RDF) is produced by processing municipal solid waste to extract combustible materials, which are then used as an alternative fuel in energy-intensive industries, reducing reliance on fossil fuels. Chemical recycling involves breaking down plastic waste into its chemical components, enabling the production of new plastics with material properties comparable to virgin polymers. Both technologies contribute to waste management by diverting materials from landfills, with RDF focusing on energy recovery and chemical recycling promoting circular plastic economies.

Key Processes in Refuse-Derived Fuel Production

Refuse-Derived Fuel (RDF) production involves key processes such as sorting, shredding, and drying municipal solid waste to create a high-calorific-value fuel alternative. Mechanical separation techniques remove non-combustible materials, while magnetic and air separation enhance the purity of the combustible fraction. These processes ensure RDF meets energy recovery standards, contrasting with chemical recycling that breaks down plastics chemically for material recovery.

Chemical Recycling: Technology and Methods

Chemical recycling utilizes advanced processes such as pyrolysis, gasification, and depolymerization to break down plastic waste into valuable monomers and fuels, offering a sustainable alternative to landfill and incineration. This technology enables the recovery of raw materials with high purity, facilitating circular economy models by converting waste plastics into new polymers or energy carriers. Compared to refuse-derived fuel, chemical recycling reduces environmental impact by minimizing emissions and supporting efficient resource recovery through innovative catalysis and thermal treatment methods.

Feedstock Requirements and Material Suitability

Refuse-Derived Fuel (RDF) relies primarily on heterogeneous municipal solid waste with a high calorific value, favoring materials like plastics, paper, and textiles, whereas Chemical Recycling demands more homogeneous and contaminant-free plastic feedstock to ensure process efficiency and product quality. RDF can process mixed waste streams without stringent sorting, making it suitable for energy recovery, whereas Chemical Recycling's sensitivity to additives and polymer types requires precise feedstock segregation, often limited to specific polymers like PET and polyolefins. The feedstock purity critically impacts chemical recycling yields and catalyst longevity, contrasting with RDF's tolerance for diverse materials but lower potential for material recovery and circularity.

Environmental Impact: Emissions and Byproducts

Refuse-Derived Fuel (RDF) produces significant emissions such as carbon dioxide, nitrogen oxides, and particulate matter, contributing to air pollution and greenhouse gas accumulation. Chemical recycling, by breaking down plastics into their molecular components, generates fewer toxic byproducts and offers a cleaner alternative for waste management with reduced environmental footprint. However, the energy intensity of chemical recycling processes may offset some benefits depending on the feedstock and technology used.

Energy Efficiency and Resource Recovery

Refuse-Derived Fuel (RDF) offers high energy efficiency by converting non-recyclable waste into a combustible fuel source with a calorific value typically between 15-20 MJ/kg, enabling effective energy recovery in waste-to-energy plants. Chemical recycling enhances resource recovery by breaking down plastics into their molecular components, allowing the production of virgin-quality polymers and reducing reliance on fossil fuels, though it generally requires more energy input than RDF combustion. Evaluating both methods reveals RDF optimizes immediate energy extraction, while chemical recycling maximizes material circularity and long-term resource sustainability.

Economic Considerations: Costs and Market Viability

Refuse-derived fuel (RDF) generally benefits from lower upfront processing costs and established markets in cement kilns and power plants, making it economically viable for large-scale waste management. Chemical recycling involves higher initial investment and operational expenses due to advanced technologies, but it offers higher-value outputs like monomers that can re-enter manufacturing cycles, potentially increasing long-term profitability. Market viability of RDF depends on stable demand in energy sectors, while chemical recycling's success hinges on regulatory support and growing markets for recycled plastics.

Regulatory Framework and Compliance

Refuse-Derived Fuel (RDF) and Chemical Recycling operate under distinct regulatory frameworks that influence compliance requirements and environmental standards. RDF regulations typically fall under solid waste management and energy recovery policies, emphasizing emissions control and waste diversion targets, while Chemical Recycling is often regulated as a manufacturing process subject to chemical handling, safety standards, and product quality certifications. Navigating these regulatory landscapes requires aligning with local, national, and international laws to ensure sustainable waste management practices and minimize environmental impact.

Integration into Existing Waste Management Systems

Refuse-Derived Fuel (RDF) integrates seamlessly into existing waste management systems by utilizing sorted municipal solid waste to produce energy through combustion, aligning with current waste collection and sorting infrastructures. Chemical recycling, however, requires specialized facilities to break down plastics into basic chemicals, demanding significant upgrades in waste sorting precision and processing technology within current systems. Combining RDF and chemical recycling can enhance waste valorization by optimizing resource recovery and reducing landfill dependence in urban waste management frameworks.

Future Trends in Waste-to-Energy and Recycling Technologies

Refuse-Derived Fuel (RDF) is gaining traction as a practical waste-to-energy solution due to its high calorific value and ability to reduce landfill dependency, while chemical recycling advances offer a promising route to recover polymers with minimal environmental impact. Emerging technologies in chemical recycling, such as pyrolysis and depolymerization, enable circularity by converting plastics back into monomers for virgin-quality plastic production, surpassing mechanical recycling limits. Future trends indicate integrated systems combining RDF and chemical recycling can optimize waste management, enhance resource recovery, and significantly lower carbon footprints across the waste-to-energy and recycling sectors.

Related Important Terms

RDF-to-Syngas

Refuse-Derived Fuel (RDF) conversion to syngas offers a high-energy, versatile feedstock for chemical manufacturing and power generation, reducing landfill dependency and lowering greenhouse gas emissions. Chemical recycling, though effective for recovering materials, typically requires higher purity waste streams and may produce less energy-dense outputs compared to RDF-to-syngas processes.

Advanced Pyrolysis

Advanced pyrolysis in refuse-derived fuel (RDF) offers a transformative approach by thermochemically converting waste into high-energy syngas and bio-oil, enhancing energy recovery efficiency compared to traditional chemical recycling methods. This process reduces landfill dependency and minimizes hazardous emissions while facilitating the circular economy through the production of valuable fuels and chemicals from heterogeneous waste streams.

Feedstock Flexibility

Refuse-Derived Fuel (RDF) offers high feedstock flexibility by utilizing a wide range of combustible waste materials, including municipal solid waste, industrial waste, and non-recyclable plastics, enabling efficient energy recovery. In contrast, Chemical Recycling requires more specific feedstock quality, typically relying on cleaner plastic waste streams with minimal contamination to optimize polymer depolymerization processes.

Mechanical-Biological Treatment (MBT) RDF

Mechanical-Biological Treatment (MBT) processes organic and mixed waste streams to produce Refuse-Derived Fuel (RDF), which serves as a versatile energy source by converting waste into combustible pellets with reduced moisture and contaminants. Unlike chemical recycling, which breaks down plastics into monomers for reuse, MBT RDF emphasizes mechanical separation and biological stabilization to optimize waste-to-energy conversion and enhance landfill diversion.

Solvolysis Recycling

Refuse-derived fuel (RDF) primarily converts waste into energy through combustion, offering a lower environmental footprint compared to landfill disposal but generating greenhouse gas emissions. Solvolysis recycling, a chemical recycling method, breaks down plastic waste into monomers using solvents, enabling the production of high-quality recycled polymers with reduced carbon emissions and enhanced circularity in plastic recovery.

Gasification Blending

Refuse-derived fuel (RDF) gasification blending offers a cost-effective waste-to-energy solution by converting solid waste into syngas, which can be integrated with traditional fuels for cleaner combustion and reduced landfill dependency. Chemical recycling, while effective in breaking down plastics into monomers, often requires higher energy input and complex processing, making gasification blending of RDF a more scalable approach for diverse waste streams and circular economy goals.

Circular Carbon Fuels

Refuse-derived fuel (RDF) transforms municipal solid waste into a combustible material that can replace fossil fuels, while chemical recycling breaks down plastic waste into its molecular components to create new raw materials. Circular carbon fuels leverage both processes by converting carbon-rich waste into reusable energy carriers, enhancing sustainability and reducing greenhouse gas emissions in a closed-loop carbon system.

Depolymerization Plastics

Refuse-derived fuel (RDF) offers a waste-to-energy solution by converting mixed waste into combustible fuel, while chemical recycling employs depolymerization to break down plastics into their monomers for producing new polymers. Depolymerization of plastics enhances sustainability by enabling closed-loop recycling, reducing reliance on fossil fuels and minimizing environmental pollution compared to the energy recovery approach of RDF.

RDF Co-Incineration

Refuse-Derived Fuel (RDF) co-incineration enables efficient energy recovery from heterogeneous waste streams by converting processed solid waste into a combustible fuel, reducing landfill dependency and lowering fossil fuel consumption. In contrast to chemical recycling, which breaks down plastics into basic monomers for reuse, RDF co-incineration offers immediate waste volume reduction and energy generation but may produce higher emissions if not properly controlled.

Chemical Upcycling

Chemical upcycling transforms waste into high-value materials by breaking down complex polymers into reusable monomers, offering a sustainable alternative to refuse-derived fuel (RDF), which primarily converts waste into energy through combustion. Unlike RDF, chemical upcycling enhances circular economy goals by enabling the regeneration of plastics with improved properties and reduced environmental impact.

Refuse-Derived Fuel vs Chemical Recycling Infographic

industrydif.com

industrydif.com