Textile waste poses significant environmental challenges due to the volume of discarded fabrics sent to landfills annually. Closed-loop textile recycling offers a sustainable solution by transforming used textiles back into raw materials, reducing the need for virgin fiber production. This process minimizes resource consumption and lowers greenhouse gas emissions compared to traditional linear waste management methods.

Table of Comparison

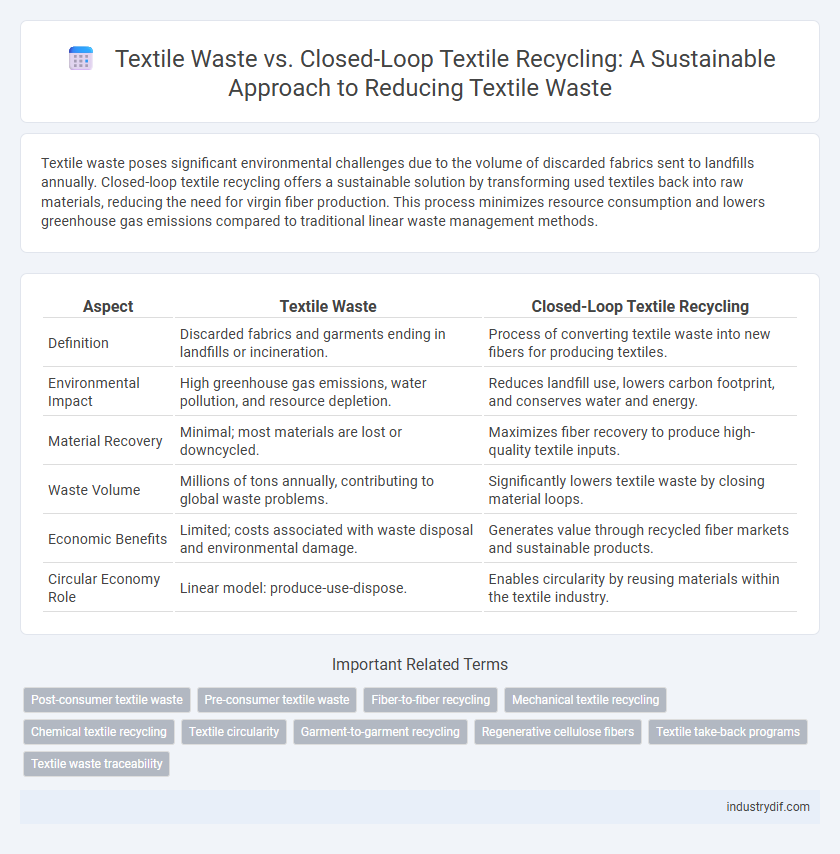

| Aspect | Textile Waste | Closed-Loop Textile Recycling |

|---|---|---|

| Definition | Discarded fabrics and garments ending in landfills or incineration. | Process of converting textile waste into new fibers for producing textiles. |

| Environmental Impact | High greenhouse gas emissions, water pollution, and resource depletion. | Reduces landfill use, lowers carbon footprint, and conserves water and energy. |

| Material Recovery | Minimal; most materials are lost or downcycled. | Maximizes fiber recovery to produce high-quality textile inputs. |

| Waste Volume | Millions of tons annually, contributing to global waste problems. | Significantly lowers textile waste by closing material loops. |

| Economic Benefits | Limited; costs associated with waste disposal and environmental damage. | Generates value through recycled fiber markets and sustainable products. |

| Circular Economy Role | Linear model: produce-use-dispose. | Enables circularity by reusing materials within the textile industry. |

Introduction to Textile Waste in the Fashion Industry

Textile waste in the fashion industry accounts for millions of tons of discarded fabrics annually, resulting in significant environmental strain through landfill overflow and resource depletion. Closed-loop textile recycling offers a sustainable solution by transforming post-consumer textiles into reusable fibers, reducing the need for virgin materials. This approach enhances circularity within fashion supply chains, minimizing waste generation and promoting eco-friendly production practices.

Defining Closed-Loop Textile Recycling Systems

Closed-loop textile recycling systems transform post-consumer fabric waste into new fibers, minimizing landfill contributions and reducing reliance on virgin materials. These processes integrate advanced sorting, fiber regeneration, and quality control technologies to maintain textile integrity and durability. By closing the material loop, closed-loop systems promote sustainable fashion and significantly lower the environmental impact of textile waste.

Environmental Impact: Textile Waste vs. Closed-Loop Solutions

Textile waste contributes significantly to environmental pollution, releasing harmful chemicals and microfibers into soil and water systems while occupying vast landfill space. Closed-loop textile recycling minimizes environmental impact by continuously converting used fabrics into new fibers, reducing the demand for virgin materials and lowering carbon emissions by up to 60%. Implementing closed-loop solutions supports sustainable resource management and mitigates the detrimental effects of textile waste on ecosystems and climate change.

Key Challenges in Managing Textile Waste

Textile waste management faces significant challenges such as the complexity of sorting mixed fibers and the high contamination levels that hinder recycling processes. Closed-loop textile recycling struggles with fiber degradation after multiple cycles, limiting the quality and usability of recycled materials. Inefficient collection systems and lack of standardized recycling technologies further impede the scalability of sustainable textile waste solutions.

Innovations Driving Closed-Loop Textile Recycling

Innovations driving closed-loop textile recycling include advanced fiber sorting technologies and chemical recycling methods that break down fabrics into their raw materials for reuse. Enhanced enzymatic treatments and AI-powered sorting systems increase material recovery rates and significantly reduce textile waste sent to landfills. These breakthroughs enable the production of new textiles from recycled fibers, supporting sustainable fashion and reducing environmental impact.

Economic Benefits of Closed-Loop Recycling Over Traditional Disposal

Closed-loop textile recycling significantly reduces landfill costs and lowers raw material expenses by reprocessing fibers into new fabrics, creating a circular economy in the fashion industry. This recycling method supports job creation within local recycling facilities and decreases reliance on virgin textile production, driving long-term economic sustainability. Traditional disposal of textile waste incurs higher environmental cleanup fees and lost economic opportunities compared to the value retained through closed-loop systems.

Barriers to Adopting Closed-Loop Recycling in Textiles

Textile waste amounts to over 92 million tons annually, yet closed-loop textile recycling faces significant barriers including high processing costs, lack of scalable technology, and limited availability of pure feedstock. The presence of blended fibers complicates the recycling process, reducing the efficiency and quality of recycled materials. Consumer awareness and insufficient industry collaboration further hinder the widespread adoption of closed-loop recycling systems.

Regulatory Frameworks Influencing Textile Waste and Recycling

Regulatory frameworks such as the European Union's Waste Framework Directive and Extended Producer Responsibility (EPR) laws significantly impact textile waste management by mandating waste reduction and promoting closed-loop textile recycling systems. These regulations enforce stringent waste sorting, encourage the use of recyclable materials, and incentivize manufacturers to design products with recyclability in mind, thereby reducing landfill dependence. Compliance with such policies accelerates the transition from linear textile waste disposal to sustainable closed-loop recycling, minimizing environmental pollution and resource depletion.

Case Studies: Successful Closed-Loop Textile Recycling Models

Case studies of closed-loop textile recycling demonstrate significant reductions in landfill waste by transforming post-consumer textiles into new garments, exemplified by brands like Patagonia and H&M's Conscious Collection. Advanced mechanical and chemical recycling technologies enable the recovery of fibers, preserving material quality and reducing reliance on virgin resources. These successful models highlight the potential of circular economy practices in minimizing textile waste and promoting sustainable fashion industry growth.

Future Trends: Scaling Closed-Loop Solutions for Textile Waste

Textile waste, accounting for over 92 million tons annually worldwide, poses significant environmental challenges due to its low recycling rates and high landfill contributions. Closed-loop textile recycling technologies are advancing, enabling fibers to be recovered and reused repeatedly without quality loss, which could reduce reliance on virgin materials by up to 50% in the next decade. Future trends emphasize scaling these solutions through innovations in chemical recycling, AI-driven sorting, and industry-wide collaborations to achieve circularity and drastically cut textile waste footprints.

Related Important Terms

Post-consumer textile waste

Post-consumer textile waste accounts for nearly 73% of total textile waste, significantly burdening landfills and contributing to environmental pollution. Closed-loop textile recycling systems recover valuable fibers from discarded garments, enabling continuous reuse within the fashion industry and drastically reducing resource consumption and carbon emissions.

Pre-consumer textile waste

Pre-consumer textile waste, including scraps and offcuts from manufacturing, significantly contributes to overall textile waste but offers a valuable resource for closed-loop textile recycling systems, which transform these materials back into fibers for new fabric production. Closed-loop recycling reduces landfill volume by recovering up to 90% of textile materials within industrial processes, enhancing sustainability in the fashion and textile industries.

Fiber-to-fiber recycling

Textile waste, primarily composed of discarded garments and fabric scraps, poses significant environmental challenges due to its volume and slow decomposition rates in landfills. Closed-loop textile recycling, especially fiber-to-fiber recycling, enables the transformation of used textiles into new fibers, reducing reliance on virgin materials and minimizing waste through sustainable circular processes.

Mechanical textile recycling

Mechanical textile recycling processes textile waste by shredding and respinning fibers into new yarn, reducing landfill impact compared to conventional textile waste disposal. Closed-loop mechanical recycling enhances sustainability by enabling repeated reuse of fibers, significantly lowering resource consumption and environmental pollution.

Chemical textile recycling

Chemical textile recycling utilizes advanced solvents and depolymerization processes to break down complex fiber blends in textile waste into their raw monomers, enabling the production of high-quality fibers comparable to virgin materials. This closed-loop method significantly reduces landfill accumulation and reliance on virgin resources by converting polyester, nylon, and other synthetic textiles into recyclable feedstock with minimal quality degradation.

Textile circularity

Textile waste accounts for approximately 92 million tons annually, with the majority ending up in landfills or incineration, contributing to environmental pollution and resource depletion. Closed-loop textile recycling enhances textile circularity by transforming used fibers into new fabrics, reducing the need for virgin materials and promoting sustainable production cycles within the fashion industry.

Garment-to-garment recycling

Textile waste amounts to over 92 million tons annually worldwide, with garment-to-garment recycling in closed-loop systems significantly reducing environmental impact by transforming old clothes into new fabrics without loss of quality. This innovative recycling method conserves resources, lowers carbon emissions by up to 70%, and decreases landfill waste compared to traditional textile disposal.

Regenerative cellulose fibers

Textile waste, largely composed of non-biodegradable synthetic fibers, accumulates in landfills, accelerating environmental degradation and resource depletion. Closed-loop textile recycling of regenerative cellulose fibers like lyocell and Tencel enables the recovery and reuse of raw materials, reducing waste output and promoting sustainable fiber production.

Textile take-back programs

Textile take-back programs significantly reduce textile waste by collecting used garments for closed-loop textile recycling, which transforms fibers into new fabric, minimizing landfill contributions. These programs enhance resource efficiency and support sustainable fashion by promoting circularity in the textile industry.

Textile waste traceability

Textile waste traceability enhances accountability by tracking discarded fabrics from consumer use to recycling facilities, minimizing illegal dumping and loss during waste management. Closed-loop textile recycling relies on accurate traceability systems to efficiently sort, process, and convert end-of-life garments into new fibers, promoting sustainable circularity in the fashion industry.

Textile Waste vs Closed-Loop Textile Recycling Infographic

industrydif.com

industrydif.com