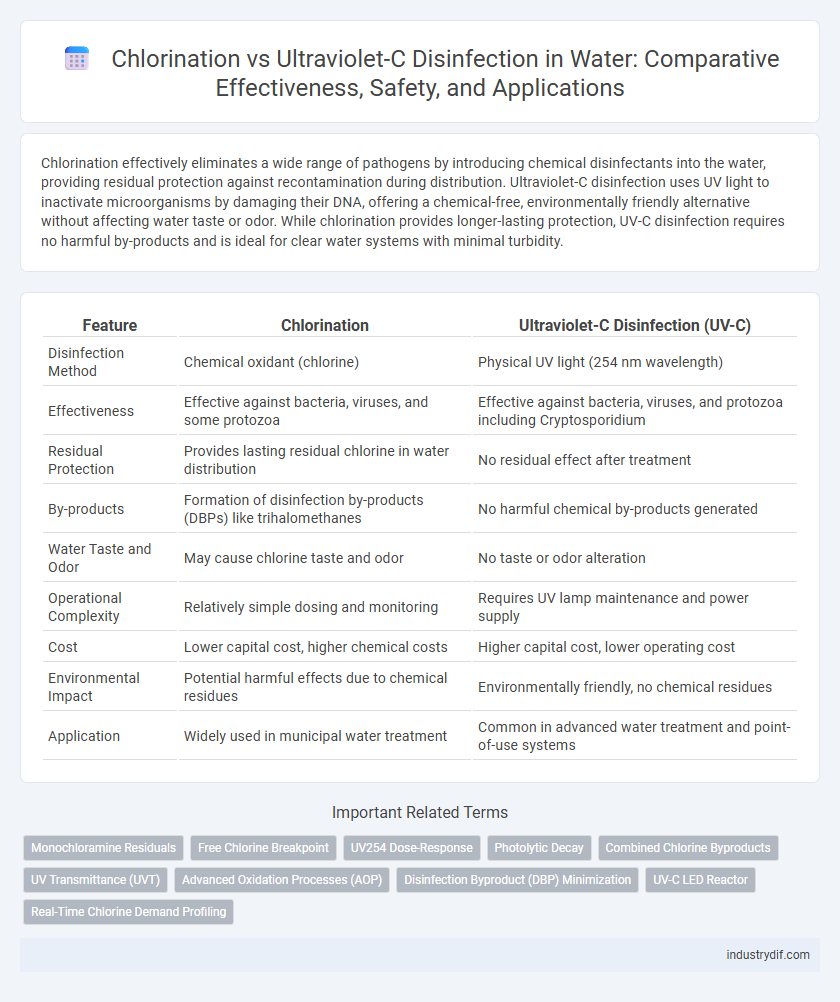

Chlorination effectively eliminates a wide range of pathogens by introducing chemical disinfectants into the water, providing residual protection against recontamination during distribution. Ultraviolet-C disinfection uses UV light to inactivate microorganisms by damaging their DNA, offering a chemical-free, environmentally friendly alternative without affecting water taste or odor. While chlorination provides longer-lasting protection, UV-C disinfection requires no harmful by-products and is ideal for clear water systems with minimal turbidity.

Table of Comparison

| Feature | Chlorination | Ultraviolet-C Disinfection (UV-C) |

|---|---|---|

| Disinfection Method | Chemical oxidant (chlorine) | Physical UV light (254 nm wavelength) |

| Effectiveness | Effective against bacteria, viruses, and some protozoa | Effective against bacteria, viruses, and protozoa including Cryptosporidium |

| Residual Protection | Provides lasting residual chlorine in water distribution | No residual effect after treatment |

| By-products | Formation of disinfection by-products (DBPs) like trihalomethanes | No harmful chemical by-products generated |

| Water Taste and Odor | May cause chlorine taste and odor | No taste or odor alteration |

| Operational Complexity | Relatively simple dosing and monitoring | Requires UV lamp maintenance and power supply |

| Cost | Lower capital cost, higher chemical costs | Higher capital cost, lower operating cost |

| Environmental Impact | Potential harmful effects due to chemical residues | Environmentally friendly, no chemical residues |

| Application | Widely used in municipal water treatment | Common in advanced water treatment and point-of-use systems |

Introduction to Water Disinfection Methods

Water disinfection methods primarily include chlorination and ultraviolet-C (UV-C) disinfection, each targeting microbial contaminants to ensure safe drinking water. Chlorination uses chlorine compounds to chemically inactivate bacteria, viruses, and protozoa, providing residual protection within distribution systems. UV-C disinfection employs short-wavelength ultraviolet light to disrupt microbial DNA, effectively neutralizing pathogens without chemical byproducts.

Overview of Chlorination in Water Treatment

Chlorination in water treatment involves adding chlorine or chlorine compounds to water to eliminate harmful pathogens and ensure microbial safety. It is widely used due to its effectiveness against bacteria, viruses, and protozoa and provides a residual disinfectant effect that helps prevent recontamination in distribution systems. Chlorination is cost-effective, easy to implement, and adaptable to various water sources, making it a globally preferred method for municipal and industrial water disinfection.

Fundamentals of Ultraviolet-C (UV-C) Disinfection

Ultraviolet-C (UV-C) disinfection utilizes wavelengths between 200-280 nanometers to inactivate microorganisms by damaging their DNA and RNA, preventing replication. Unlike chlorination, UV-C does not introduce chemicals or alter water taste and odor, making it ideal for sensitive applications. UV-C systems provide rapid microbial inactivation with minimal formation of disinfection byproducts, offering an environmentally friendly alternative for water treatment.

Mechanisms of Action: Chlorination vs. UV-C

Chlorination disinfects water by releasing hypochlorous acid, which penetrates microbial cell walls and disrupts vital enzymatic functions, leading to cell death; it also provides a residual disinfectant effect in distribution systems. Ultraviolet-C (UV-C) disinfection inactivates pathogens by emitting light at 254 nm wavelength, causing thymine dimers in microbial DNA and RNA, thereby preventing replication. While chlorination offers prolonged protection, UV-C delivers rapid, chemical-free neutralization without producing disinfection byproducts.

Efficacy Against Waterborne Pathogens

Chlorination effectively inactivates a broad spectrum of waterborne pathogens, including bacteria, viruses, and protozoa, by disrupting their cellular functions through oxidation. Ultraviolet-C (UV-C) disinfection neutralizes microorganisms by damaging their DNA or RNA, preventing replication, and is particularly efficient against chlorine-resistant pathogens such as Cryptosporidium and Giardia. While chlorination provides residual disinfection to maintain water safety during distribution, UV-C requires no chemical additives and produces no disinfection byproducts, offering a safer alternative in specific water treatment scenarios.

Environmental and Health Impacts

Chlorination, a common water disinfection method, effectively eliminates pathogens but produces disinfection byproducts like trihalomethanes, which pose carcinogenic risks and impact aquatic ecosystems. Ultraviolet-C (UV-C) disinfection offers a chemical-free alternative, inactivating microorganisms without generating harmful residues, thus minimizing environmental contamination and health hazards. However, UV-C disinfection requires proper maintenance and energy input, influencing its sustainability compared to chlorination.

Installation and Operational Considerations

Chlorination systems require careful handling of chemical storage, regular monitoring, and dosing control equipment, which can increase operational complexity and safety risks during installation. Ultraviolet-C (UV-C) disinfection units offer straightforward installation with minimal space requirements and no chemical usage, leading to lower operational hazards and simpler maintenance routines. Both methods demand reliable power supply, but UV-C systems often benefit from automated cleaning mechanisms to maintain lamp efficiency and reduce manual intervention.

Cost Analysis: Chlorination vs. UV-C

Chlorination typically incurs lower upfront costs due to its simple infrastructure and readily available chemicals, making it more affordable for large-scale water treatment. Ultraviolet-C (UV-C) disinfection involves higher initial investment in specialized lamps and electrical components but offers reduced operational costs by eliminating chemical purchase and storage. Over time, UV-C systems may present cost benefits in maintenance and environmental compliance, especially in settings prioritizing chemical-free water treatment.

Regulatory Standards and Compliance

Chlorination meets stringent regulatory standards such as EPA and WHO guidelines for residual disinfection and microbial control in drinking water, ensuring compliance with established safety limits on disinfection byproducts like trihalomethanes. Ultraviolet-C (UV-C) disinfection complies with EPA Ultraviolet Disinfection Guidance Manual criteria, providing effective pathogen inactivation without chemical residuals but requires validation for water quality parameters such as turbidity to meet regulatory acceptance. Both methods are recognized by regulatory agencies worldwide, but chlorination remains the standard for long-term residual protection, while UV-C is increasingly adopted for secondary disinfection and in systems targeting chemical-free treatment solutions.

Choosing the Right Disinfection Method for Your Facility

Choosing the right water disinfection method between chlorination and ultraviolet-C (UV-C) relies on facility-specific factors such as water quality, operational complexity, and safety requirements. Chlorination is effective against a broad spectrum of pathogens and provides residual disinfection beneficial for distribution systems, while UV-C offers chemical-free, rapid inactivation of microorganisms without harmful byproducts. Facilities with sensitive ecosystems or indoor treatment may prefer UV-C for its environmental safety, whereas large-scale municipal plants often select chlorination for cost-efficiency and established regulatory acceptance.

Related Important Terms

Monochloramine Residuals

Monochloramine residuals, commonly used in chlorination, provide long-lasting disinfectant effects in water distribution systems, reducing the risk of microbial regrowth. Ultraviolet-C (UV-C) disinfection does not create these residuals, necessitating additional treatments to maintain water quality during distribution.

Free Chlorine Breakpoint

Free chlorine breakpoint occurs during chlorination when the chlorine demand of water is fully satisfied, leading to a sudden rise in free chlorine residual critical for effective microbial disinfection. Ultraviolet-C disinfection bypasses chemical reactions by using germicidal wavelengths to inactivate microorganisms, eliminating concerns over breakpoint chlorination and chemical byproducts.

UV254 Dose-Response

The UV254 dose-response relationship demonstrates that ultraviolet-C disinfection effectively inactivates pathogens by disrupting their nucleic acids, providing a chemical-free alternative to chlorination. While chlorination relies on oxidative damage and residual disinfectant presence, UV254 enables precise control over microbial inactivation without forming harmful disinfection byproducts.

Photolytic Decay

Chlorination relies on chemical oxidation, producing residual disinfectants that decay over time, whereas Ultraviolet-C disinfection uses photolytic decay to directly disrupt microbial DNA without chemical residues. Photolytic decay in UV-C systems ensures immediate pathogen inactivation by breaking molecular bonds, offering rapid water disinfection without the formation of harmful byproducts common in chlorination processes.

Combined Chlorine Byproducts

Chlorination produces combined chlorine byproducts such as chloramines, which can cause unpleasant odors, skin irritation, and respiratory issues. Ultraviolet-C disinfection eliminates pathogens without forming harmful chlorinated compounds, making it a safer alternative for water treatment regarding combined chlorine byproducts.

UV Transmittance (UVT)

Chlorination effectively disinfects water but can produce harmful disinfection byproducts, whereas Ultraviolet-C (UV-C) disinfection relies heavily on UV Transmittance (UVT) levels to ensure microbial inactivation, with higher UVT indicating clearer water and more efficient UV penetration. Water with UVT above 70% typically allows optimal UV-C effectiveness, making UV disinfection preferable for treated water with low turbidity and minimal organic contamination.

Advanced Oxidation Processes (AOP)

Advanced Oxidation Processes (AOP) enhance water treatment by generating highly reactive hydroxyl radicals that effectively degrade organic contaminants, outperforming traditional chlorination in eliminating resistant pathogens and reducing disinfection byproducts. Ultraviolet-C (UV-C) disinfection combined with AOPs offers superior microbial inactivation and improved water quality by breaking down complex pollutants that chlorination alone cannot address.

Disinfection Byproduct (DBP) Minimization

Ultraviolet-C (UV-C) disinfection effectively inactivates pathogens without producing harmful disinfection byproducts (DBPs), unlike chlorination, which can generate carcinogenic chlorinated DBPs such as trihalomethanes (THMs) and haloacetic acids (HAAs). Minimizing DBP formation through UV-C technology enhances water safety while meeting regulatory standards for drinking water quality.

UV-C LED Reactor

UV-C LED reactors offer energy-efficient and chemical-free water disinfection by emitting precise germicidal wavelengths that inactivate microbes without forming harmful byproducts, unlike traditional chlorination which can produce disinfection byproducts such as trihalomethanes. UV-C LED technology provides rapid microbial inactivation, compact reactor designs, and longer operational lifespans, making it ideal for point-of-use water treatment systems and environmentally sustainable applications.

Real-Time Chlorine Demand Profiling

Real-time chlorine demand profiling enables precise adjustment of chlorine dosage, improving the effectiveness of chlorination by continuously measuring organic and inorganic contaminants that consume chlorine. Ultraviolet-C disinfection offers a chemical-free alternative by inactivating microorganisms through DNA disruption, yet lacks residual protection, making chlorine demand profiling essential for maintaining ongoing water safety in chlorination systems.

Chlorination vs Ultraviolet-C Disinfection Infographic

industrydif.com

industrydif.com