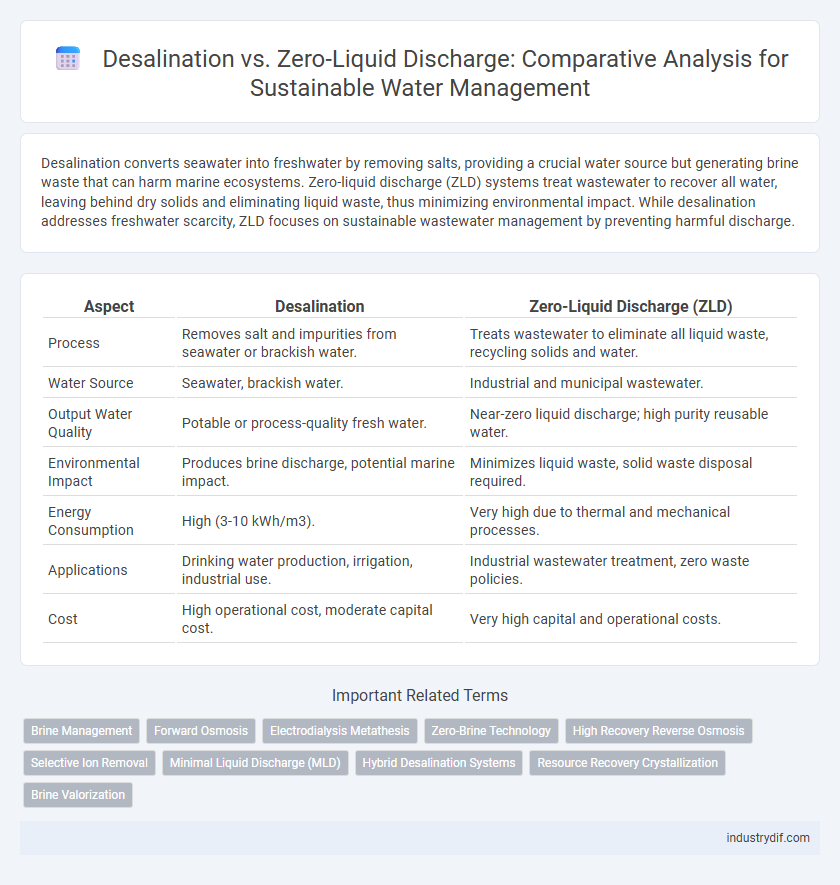

Desalination converts seawater into freshwater by removing salts, providing a crucial water source but generating brine waste that can harm marine ecosystems. Zero-liquid discharge (ZLD) systems treat wastewater to recover all water, leaving behind dry solids and eliminating liquid waste, thus minimizing environmental impact. While desalination addresses freshwater scarcity, ZLD focuses on sustainable wastewater management by preventing harmful discharge.

Table of Comparison

| Aspect | Desalination | Zero-Liquid Discharge (ZLD) |

|---|---|---|

| Process | Removes salt and impurities from seawater or brackish water. | Treats wastewater to eliminate all liquid waste, recycling solids and water. |

| Water Source | Seawater, brackish water. | Industrial and municipal wastewater. |

| Output Water Quality | Potable or process-quality fresh water. | Near-zero liquid discharge; high purity reusable water. |

| Environmental Impact | Produces brine discharge, potential marine impact. | Minimizes liquid waste, solid waste disposal required. |

| Energy Consumption | High (3-10 kWh/m3). | Very high due to thermal and mechanical processes. |

| Applications | Drinking water production, irrigation, industrial use. | Industrial wastewater treatment, zero waste policies. |

| Cost | High operational cost, moderate capital cost. | Very high capital and operational costs. |

Introduction to Desalination and Zero-Liquid Discharge

Desalination involves the process of removing salts and impurities from seawater or brackish water to produce fresh, potable water, utilizing methods such as reverse osmosis and thermal distillation. Zero-Liquid Discharge (ZLD) is an advanced treatment technology designed to eliminate wastewater discharge by recovering nearly all water from industrial effluents through processes including evaporation, crystallization, and membrane filtration. Both technologies aim to address water scarcity, with desalination focusing on increasing freshwater supply, while ZLD prioritizes sustainable water recycling and minimizing environmental impact.

Key Definitions and Terminologies

Desalination is a process that removes salts and impurities from seawater or brackish water to produce fresh water, primarily through reverse osmosis or thermal distillation techniques. Zero-Liquid Discharge (ZLD) is an advanced waste management approach aiming to eliminate any liquid waste by recovering all water and converting solid residues, often using evaporation, crystallization, and membrane technologies. Key terminologies include total dissolved solids (TDS) for measuring salinity in desalination, and brine concentrate, a highly saline byproduct managed differently in desalination and ZLD systems.

Overview of Desalination Technologies

Desalination technologies primarily include reverse osmosis, multi-stage flash distillation, and electrodialysis, each offering distinct advantages in removing salts and impurities from seawater or brackish water. Reverse osmosis is the most widely used method due to its energy efficiency and scalability, employing semi-permeable membranes to filter out dissolved solids. Innovative methods like multi-effect distillation and membrane distillation are also gaining traction for their potential in enhancing water recovery and reducing energy consumption.

Zero-Liquid Discharge Process Explained

The Zero-Liquid Discharge (ZLD) process eliminates wastewater by recovering almost all water and converting salts and solids into dry, reusable materials through advanced filtration, evaporation, and crystallization techniques. Unlike traditional desalination, which primarily removes salts to produce freshwater but generates brine waste, ZLD ensures no liquid waste is discharged, significantly reducing environmental impact. This closed-loop approach maximizes resource recovery, supports stricter environmental regulations, and is ideal for industries requiring minimal water footprints.

Comparative Energy Consumption

Desalination technologies typically consume between 3 to 10 kWh per cubic meter of water, depending on methods like reverse osmosis or thermal distillation. Zero-Liquid Discharge (ZLD) systems require significantly higher energy inputs, often exceeding 15 kWh per cubic meter, due to advanced processes such as evaporation and crystallization for complete wastewater recovery. The substantial difference in energy consumption highlights desalination as more energy-efficient for producing potable water compared to ZLD's comprehensive waste minimization approach.

Environmental Impact Assessment

Desalination plants often produce brine with high salinity, posing risks to marine ecosystems when discharged untreated. Zero-Liquid Discharge (ZLD) systems minimize wastewater release by recovering and reusing all water and solids, significantly reducing environmental pollution. Lifecycle assessments reveal ZLD's potential to lower ecological footprints despite higher energy consumption compared to conventional desalination.

Cost Analysis: Investment and Opex

Desalination typically requires high capital investment and significant operational expenditures due to energy-intensive processes like reverse osmosis, with costs influenced by feedwater salinity and plant capacity. Zero-Liquid Discharge (ZLD) systems involve even higher initial investments and operational costs driven by complex thermal and mechanical treatments to achieve near-total water recovery. While ZLD reduces environmental discharge and water waste, its elevated capex and opex make it less economically feasible compared to traditional desalination in many applications.

Water Quality and Resource Recovery

Desalination processes primarily focus on removing salts and impurities to produce potable water, achieving high water quality but often generating brine waste. Zero-Liquid Discharge (ZLD) systems maximize resource recovery by recycling all wastewater streams, reducing environmental impact while recovering valuable minerals and salts. ZLD achieves better overall resource utilization but requires higher energy inputs compared to conventional desalination methods.

Regulatory Compliance and Industry Standards

Desalination processes must comply with stringent environmental regulations aimed at limiting brine discharge and protecting marine ecosystems, often governed by bodies like the EPA and regional water authorities. Zero-Liquid Discharge (ZLD) systems offer enhanced regulatory compliance by eliminating liquid waste, thereby meeting stricter industry standards for hazardous discharge and water reuse mandates. Both technologies require adherence to ISO standards for water quality and treatment, but ZLD's ability to recycle water fully positions it as a superior solution in sectors with tight regulatory constraints.

Future Trends and Innovations

Desalination technologies are advancing with energy-efficient methods like reverse osmosis and forward osmosis to meet growing freshwater demands, while zero-liquid discharge (ZLD) systems are evolving to achieve near-complete recovery of water and valuable salts from industrial wastewater. Future trends emphasize integrating renewable energy sources such as solar and wind with desalination and ZLD to reduce carbon footprints and operational costs. Innovations in membrane materials, real-time monitoring using AI, and modular designs are driving enhanced sustainability and scalability in water treatment for diverse applications.

Related Important Terms

Brine Management

Desalination produces concentrated brine requiring effective disposal or treatment, while Zero-Liquid Discharge (ZLD) systems minimize environmental impact by recovering nearly all water and converting brine into solid waste. Advanced brine management techniques in ZLD include thermal evaporation, crystallization, and chemical precipitation, offering sustainable solutions to mitigate marine pollution and comply with stringent discharge regulations.

Forward Osmosis

Forward osmosis in desalination offers energy-efficient water extraction by using natural osmotic pressure to separate salts, minimizing chemical use and membrane fouling. Zero-liquid discharge systems complement this by concentrating brine to solid waste, achieving near-zero wastewater and maximizing freshwater recovery for sustainable water management.

Electrodialysis Metathesis

Electrodialysis Metathesis (EDM) enhances desalination by selectively removing specific ions, improving water recovery rates compared to Zero-Liquid Discharge (ZLD) systems that typically concentrate brine for complete elimination of liquid waste. This method optimizes energy efficiency and reduces operational costs by combining ion exchange membranes with electric fields, making EDM a promising technology for sustainable water treatment in industrial and agricultural applications.

Zero-Brine Technology

Zero-brine technology in zero-liquid discharge systems offers a sustainable alternative to traditional desalination by eliminating brine waste and enabling complete water recovery. This innovative approach reduces environmental impact and operational costs while providing a reliable source of potable water, making it a transformative solution for water-scarce regions.

High Recovery Reverse Osmosis

High Recovery Reverse Osmosis (HRRO) enhances desalination efficiency by recovering up to 85-90% of feedwater, significantly reducing brine volume compared to conventional desalination. Zero-Liquid Discharge (ZLD) further processes HRRO brine through evaporation and crystallization, ensuring nearly 100% water reuse while minimizing environmental discharge and resource waste.

Selective Ion Removal

Desalination techniques such as reverse osmosis primarily focus on removing a broad spectrum of salts and impurities to produce potable water, whereas Zero-Liquid Discharge (ZLD) systems emphasize selective ion removal to recover valuable salts and minimize brine disposal. Advanced ion-selective membranes and adsorbents used in ZLD enable precise extraction of specific ions like sodium, chloride, and heavy metals, optimizing resource recovery and environmental sustainability.

Minimal Liquid Discharge (MLD)

Minimal Liquid Discharge (MLD) systems optimize water reuse by significantly reducing brine volume compared to traditional desalination, thereby lowering environmental impact and operational costs. MLD bridges the gap between conventional desalination and Zero-Liquid Discharge (ZLD) by concentrating waste streams while minimizing liquid effluent, enhancing sustainable water management in industries.

Hybrid Desalination Systems

Hybrid desalination systems combine reverse osmosis and zero-liquid discharge technologies, maximizing water recovery while minimizing brine discharge and environmental impact. These integrated solutions enhance resource efficiency by converting saline water and wastewater into potable water with near-zero byproduct waste streams.

Resource Recovery Crystallization

Resource Recovery Crystallization maximizes water reuse by efficiently extracting pure salts and minerals from brine, reducing waste discharge in desalination and zero-liquid discharge (ZLD) systems. This technology enhances sustainability by transforming concentrated brine into valuable byproducts, minimizing environmental impact and operational costs.

Brine Valorization

Brine valorization enhances both desalination and zero-liquid discharge (ZLD) processes by recovering valuable minerals and reducing environmental impact from concentrated brine waste. Integrating brine valorization enables sustainable resource extraction, minimizing disposal costs and improving overall water treatment efficiency.

Desalination vs Zero-Liquid Discharge Infographic

industrydif.com

industrydif.com