Water filtration primarily removes suspended solids, sediments, and some microorganisms using physical barriers, while membrane bioreactors combine biological treatment and membrane filtration for advanced purification, effectively removing organic matter and pathogens. Membrane bioreactors offer higher efficiency and produce superior effluent quality, making them ideal for wastewater treatment and reuse applications. Water filtration is typically more cost-effective for basic purification but lacks the comprehensive contaminant removal capabilities of membrane bioreactors.

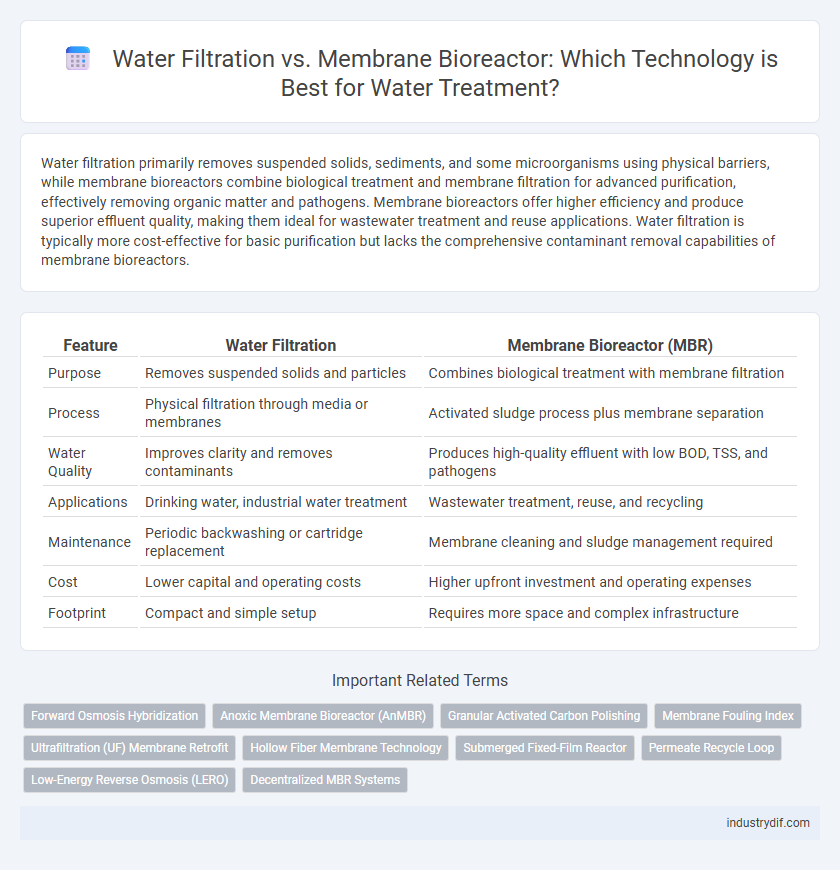

Table of Comparison

| Feature | Water Filtration | Membrane Bioreactor (MBR) |

|---|---|---|

| Purpose | Removes suspended solids and particles | Combines biological treatment with membrane filtration |

| Process | Physical filtration through media or membranes | Activated sludge process plus membrane separation |

| Water Quality | Improves clarity and removes contaminants | Produces high-quality effluent with low BOD, TSS, and pathogens |

| Applications | Drinking water, industrial water treatment | Wastewater treatment, reuse, and recycling |

| Maintenance | Periodic backwashing or cartridge replacement | Membrane cleaning and sludge management required |

| Cost | Lower capital and operating costs | Higher upfront investment and operating expenses |

| Footprint | Compact and simple setup | Requires more space and complex infrastructure |

Introduction to Water Filtration and Membrane Bioreactor Technologies

Water filtration removes suspended solids, bacteria, and contaminants through physical, chemical, or biological processes, enhancing water clarity and safety. Membrane bioreactor (MBR) technology combines activated sludge treatment with membrane filtration, offering high-efficiency removal of organic matter and pathogens in wastewater treatment. MBR systems provide compact design, superior effluent quality, and reduced sludge production compared to conventional filtration methods.

Core Principles of Water Filtration Systems

Water filtration systems primarily rely on physical and chemical processes to remove contaminants, particles, and impurities from water, utilizing media like sand, activated carbon, or chemical coagulants. These systems focus on sediment filtration, activated carbon absorption, and chemical treatment to improve water quality by targeting turbidity, chlorine taste, and organic pollutants. In contrast, membrane bioreactors combine biological degradation with membrane filtration, offering advanced treatment by simultaneously removing organic matter and suspended solids through microfiltration or ultrafiltration membranes.

Membrane Bioreactor (MBR) Technology Overview

Membrane Bioreactor (MBR) technology integrates conventional biological treatment with membrane filtration, effectively removing suspended solids, bacteria, and organic contaminants from wastewater. MBR systems utilize microfiltration or ultrafiltration membranes, enabling high-quality effluent with reduced footprint and enhanced operational efficiency compared to traditional water filtration methods. This advanced technology is widely adopted in municipal and industrial wastewater treatment for producing reusable water while minimizing sludge production.

Key Components of Traditional Water Filtration

Traditional water filtration relies on key components such as sand filters, activated carbon filters, and sediment filters to remove physical impurities and organic contaminants. These systems utilize granular media and adsorption processes to improve water clarity and taste while reducing chlorine and volatile compounds. Unlike membrane bioreactors, traditional filtration does not incorporate biological treatment or membrane separation, limiting its effectiveness against dissolved solids and microbial pathogens.

Comparative Analysis: Filtration Efficiency

Water filtration systems use various physical and chemical processes to remove particles, contaminants, and microorganisms, achieving removal efficiencies ranging from 85% to 95% for common pollutants. Membrane bioreactors (MBRs) integrate membrane filtration with biological treatment, offering superior filtration efficiency of over 99% for suspended solids, bacteria, and even viruses. MBRs also provide consistent effluent quality with reduced sludge production, making them more effective for advanced wastewater treatment compared to conventional filtration methods.

Removal of Contaminants: Water Filtration vs MBR

Water filtration effectively removes suspended solids, chlorine, and some bacteria through physical and chemical processes, ensuring cleaner water. Membrane bioreactors (MBR) combine biological treatment with membrane filtration, achieving superior removal of organic contaminants, pathogens, and nutrients like nitrogen and phosphorus. MBR systems provide higher effluent quality and better contaminant removal efficiency compared to conventional water filtration methods.

Operational Costs and Energy Consumption

Water filtration generally incurs lower operational costs and energy consumption compared to membrane bioreactors, which require continuous energy for membrane aeration and cleaning processes. Membrane bioreactors offer superior treatment efficiency and higher effluent quality but demand higher maintenance expenditure and electricity use due to membrane fouling control. Optimizing energy-efficient aeration and cleaning cycles in membrane bioreactors can reduce operational costs, yet standard water filtration remains more economical for basic contaminant removal.

Maintenance Requirements and System Longevity

Water filtration systems typically require routine maintenance such as regular filter replacements and periodic cleaning to prevent clogging and maintain optimal flow rates. Membrane bioreactors (MBRs) demand more intensive upkeep, including membrane backflushing, chemical cleaning, and monitoring for membrane fouling to ensure consistent performance. While water filtration systems may have shorter lifespans, properly maintained MBRs often offer extended system longevity due to advanced membrane durability and integrated biological treatment processes.

Applications: Industrial and Municipal Water Treatment

Water filtration systems effectively remove suspended solids, chlorine, and other contaminants in both industrial and municipal water treatment facilities, ensuring safe and clean water for various applications. Membrane bioreactors (MBRs) combine membrane filtration with biological treatment, making them ideal for wastewater treatment in municipalities and industries requiring high-quality effluent and reduced sludge production. MBR technology is particularly valuable in advanced water reuse, meeting stringent discharge standards, and handling complex wastewater streams from pharmaceuticals, food processing, and chemical manufacturing.

Future Trends in Filtration and MBR Technology

Future trends in water filtration emphasize advanced membrane materials with enhanced permeability, fouling resistance, and energy efficiency, driving more sustainable treatment processes. Membrane Bioreactor (MBR) technology is evolving through integration with IoT and AI for real-time monitoring and optimized sludge management, improving operational reliability. Innovations in hybrid systems combining MBR with photocatalysis or nanofiltration are expanding the scope of contaminant removal for industrial and municipal water reuse applications.

Related Important Terms

Forward Osmosis Hybridization

Forward osmosis hybridization combines membrane bioreactor (MBR) technology with forward osmosis (FO) to enhance water filtration efficiency, enabling higher contaminant removal and reduced fouling. This integration leverages FO's low-energy osmotic process alongside MBR's biological treatment, optimizing wastewater reclamation and improving overall membrane lifespan.

Anoxic Membrane Bioreactor (AnMBR)

Anoxic Membrane Bioreactors (AnMBRs) combine membrane filtration with anaerobic treatment, enabling efficient removal of organic contaminants and nitrogen compounds while producing biogas for energy recovery. This advanced water filtration technology offers enhanced biodegradation under anoxic conditions, reducing sludge production and improving effluent quality compared to conventional membrane bioreactors.

Granular Activated Carbon Polishing

Granular Activated Carbon (GAC) polishing enhances water filtration by effectively removing organic compounds, chlorine, and taste-odor contaminants, improving water quality before or after membrane bioreactor (MBR) treatment. Integrating GAC polishing with MBR systems optimizes the removal of micropollutants and extends membrane lifespan by reducing fouling and maintaining system efficiency.

Membrane Fouling Index

Membrane Bioreactors (MBRs) exhibit a lower Membrane Fouling Index (MFI) compared to conventional water filtration methods, enhancing filtration efficiency and extending membrane lifespan. This reduced fouling propensity in MBR systems results in improved water quality and operational stability in wastewater treatment processes.

Ultrafiltration (UF) Membrane Retrofit

Ultrafiltration (UF) membrane retrofit in water filtration significantly enhances treatment efficiency by removing suspended solids, bacteria, and viruses with pore sizes typically ranging from 0.01 to 0.1 microns. Integrating UF membranes within membrane bioreactor (MBR) systems improves permeate quality and reduces fouling compared to traditional filtration methods, optimizing operational costs and ensuring compliance with stringent water quality standards.

Hollow Fiber Membrane Technology

Hollow fiber membrane technology in water filtration offers high surface area and efficient contaminant removal, making it a preferred choice in membrane bioreactor (MBR) systems for wastewater treatment. This technology enhances filtration performance by providing effective separation of solids and microorganisms, leading to improved effluent quality and operational reliability in MBR applications.

Submerged Fixed-Film Reactor

Submerged Fixed-Film Reactors (SFFRs) in membrane bioreactor systems enhance wastewater treatment efficiency by combining biological degradation with membrane filtration, outperforming conventional water filtration methods in removing organic contaminants and suspended solids. The fixed-film biofilm provides a stable microbial environment, improving biodegradation rates and reducing membrane fouling, which results in higher water quality and extended membrane lifespan.

Permeate Recycle Loop

The permeate recycle loop in water filtration enhances system efficiency by redirecting treated water back into the feed, reducing waste and increasing overall recovery rates. Membrane bioreactors leverage this loop to maintain optimal biomass concentration, improve contaminant removal, and extend membrane lifespan.

Low-Energy Reverse Osmosis (LERO)

Low-Energy Reverse Osmosis (LERO) in water filtration reduces energy consumption by utilizing advanced membrane technology combined with optimized system design, offering significant efficiency improvements over traditional Membrane Bioreactors (MBRs). LERO achieves high contaminant rejection rates while maintaining lower operational costs and environmental impact, making it a preferred solution for sustainable water treatment.

Decentralized MBR Systems

Decentralized Membrane Bioreactor (MBR) systems integrate advanced membrane filtration with biological treatment to provide superior effluent quality compared to traditional water filtration methods. These systems enable onsite wastewater reuse by efficiently removing contaminants and pathogens, reducing reliance on centralized infrastructure, and promoting sustainability in water management.

Water Filtration vs Membrane Bioreactor Infographic

industrydif.com

industrydif.com