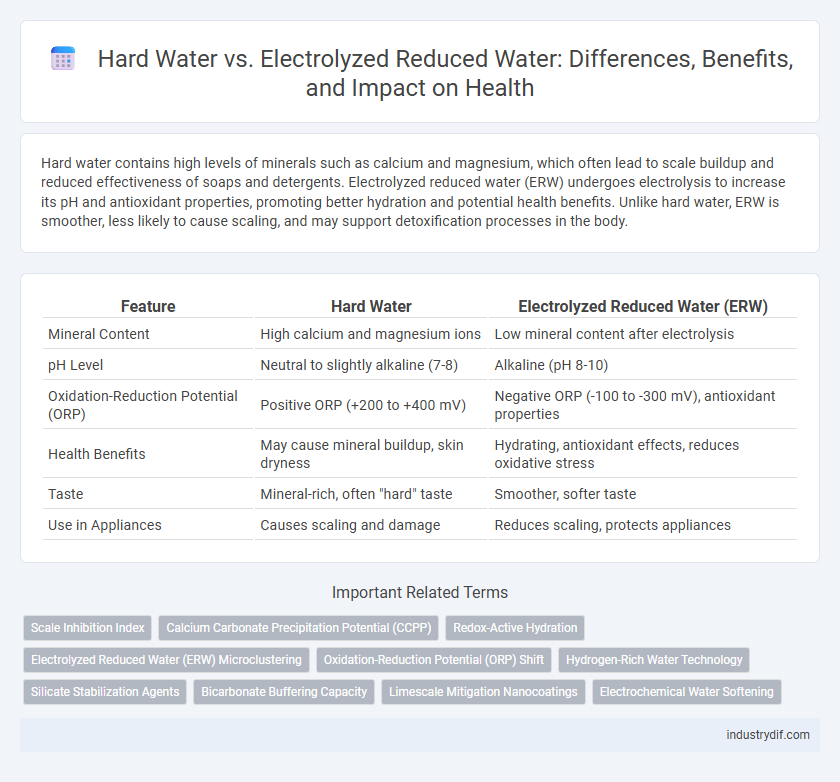

Hard water contains high levels of minerals such as calcium and magnesium, which often lead to scale buildup and reduced effectiveness of soaps and detergents. Electrolyzed reduced water (ERW) undergoes electrolysis to increase its pH and antioxidant properties, promoting better hydration and potential health benefits. Unlike hard water, ERW is smoother, less likely to cause scaling, and may support detoxification processes in the body.

Table of Comparison

| Feature | Hard Water | Electrolyzed Reduced Water (ERW) |

|---|---|---|

| Mineral Content | High calcium and magnesium ions | Low mineral content after electrolysis |

| pH Level | Neutral to slightly alkaline (7-8) | Alkaline (pH 8-10) |

| Oxidation-Reduction Potential (ORP) | Positive ORP (+200 to +400 mV) | Negative ORP (-100 to -300 mV), antioxidant properties |

| Health Benefits | May cause mineral buildup, skin dryness | Hydrating, antioxidant effects, reduces oxidative stress |

| Taste | Mineral-rich, often "hard" taste | Smoother, softer taste |

| Use in Appliances | Causes scaling and damage | Reduces scaling, protects appliances |

Understanding Hard Water: Definition and Characteristics

Hard water contains high concentrations of calcium and magnesium ions, which cause mineral buildup and reduce soap effectiveness. It often leads to scale deposits in pipes and appliances, resulting in decreased efficiency and increased maintenance costs. Understanding its mineral composition is essential for addressing water hardness issues and improving water quality.

Electrolyzed Reduced Water: What It Is

Electrolyzed Reduced Water (ERW) is created by passing an electric current through water, causing a separation into alkaline and acidic components, with the alkaline portion known for its antioxidant properties. ERW contains dissolved hydrogen molecules that help neutralize free radicals and reduce oxidative stress in the body. This type of water typically has a higher pH and negative oxidation-reduction potential (ORP), making it distinct from hard water, which primarily contains high levels of calcium and magnesium minerals.

Chemical Composition: Hard Water vs Electrolyzed Reduced Water

Hard water contains high levels of calcium and magnesium bicarbonates, which contribute to scale formation and reduce water softness. Electrolyzed Reduced Water (ERW) is rich in dissolved hydrogen gas and has a lower oxidation-reduction potential (ORP), offering antioxidant properties. Unlike hard water, ERW typically has fewer mineral ions responsible for hardness, resulting in improved solubility and bioavailability of minerals.

Sources and Prevalence in Industry

Hard water primarily originates from natural sources such as groundwater rich in calcium and magnesium minerals, commonly found in regions with limestone or chalk bedrock, and it prevails in industries like textile, food processing, and manufacturing where mineral deposits can cause scaling and equipment damage. Electrolyzed Reduced Water (ERW) is produced through electrolysis processes in water treatment facilities and is increasingly applied in sectors such as healthcare, agriculture, and food hygiene for its antimicrobial properties and antioxidant effects. While hard water is widespread due to geological factors influencing water hardness, ERW's prevalence is growing with technological advancements aimed at enhancing water quality and sanitation in industrial applications.

Impact on Equipment and Infrastructure

Hard water causes scale buildup in pipes and appliances, leading to reduced efficiency and increased maintenance costs. Electrolyzed reduced water, with its lower mineral content and antioxidant properties, minimizes corrosion and scaling, extending the lifespan of equipment and infrastructure. Using electrolyzed reduced water improves operational reliability and reduces the risk of damage associated with mineral deposits.

Effects on Cleaning and Detergent Efficiency

Hard water contains high levels of calcium and magnesium ions that react with soap, forming insoluble curds that reduce cleaning efficiency and increase detergent usage. Electrolyzed Reduced Water (ERW) exhibits enhanced cleaning properties due to its low surface tension and higher reduction-oxidation potential, which help dissolve dirt and grease more effectively. Using ERW can lead to significant detergent savings and improved stain removal compared to hard water.

Role in Industrial Processes and Manufacturing

Hard water, characterized by high concentrations of calcium and magnesium ions, causes scale buildup in industrial boilers and heat exchangers, reducing efficiency and increasing maintenance costs. Electrolyzed reduced water (ERW), with its lower mineral content and antioxidative properties, enhances cleaning and cooling processes, improving equipment longevity and product quality. Industries utilizing ERW report reduced chemical usage and lower operational downtime compared to systems relying on hard water.

Health and Safety Considerations

Hard water contains high levels of minerals such as calcium and magnesium, which can lead to the buildup of scale in pipes and reduce the effectiveness of soap, potentially causing skin irritation and dryness. Electrolyzed Reduced Water (ERW) is characterized by its antioxidant properties and alkaline pH, which may support hydration and neutralize free radicals, promoting better cellular health. Safety considerations include the potential for mineral imbalances with hard water consumption and the importance of verifying ERW devices for proper electrolysis to avoid harmful byproducts.

Environmental Impact Comparison

Hard water contributes to increased detergent use and energy consumption during cleaning, leading to higher environmental pollution and resource depletion. Electrolyzed Reduced Water (ERW) offers a sustainable alternative by reducing chemical usage and improving water efficiency, lowering the ecological footprint of household and industrial processes. ERW systems also minimize scale formation in pipes and appliances, extending their lifespan and reducing waste from maintenance and replacements.

Choosing the Right Water Type for Industrial Applications

Hard water contains high levels of calcium and magnesium ions, leading to scale buildup and reduced equipment efficiency in industrial applications. Electrolyzed Reduced Water (ERW) offers superior corrosion resistance and enhanced cleaning properties due to its altered pH and antioxidant potential, improving machinery longevity and process outcomes. Selecting ERW over hard water minimizes maintenance costs and optimizes performance in sectors like manufacturing, food processing, and cooling systems.

Related Important Terms

Scale Inhibition Index

Hard water typically exhibits a low Scale Inhibition Index (SII) due to high concentrations of calcium and magnesium ions that promote scale formation. Electrolyzed Reduced Water (ERW) demonstrates a significantly higher SII, effectively reducing mineral scaling and improving water quality for industrial and household applications.

Calcium Carbonate Precipitation Potential (CCPP)

Hard water, characterized by high levels of calcium and magnesium ions, typically exhibits a higher Calcium Carbonate Precipitation Potential (CCPP), leading to scale formation and reduced water quality. Electrolyzed Reduced Water (ERW) shows a significantly lower CCPP due to its altered pH and redox properties, minimizing calcium carbonate precipitation and improving water softness and bioavailability.

Redox-Active Hydration

Hard water contains high levels of minerals like calcium and magnesium that can impair cellular hydration by increasing oxidative stress, whereas Electrolyzed Reduced Water (ERW) possesses negative oxidation-reduction potential (ORP) and rich molecular hydrogen, promoting redox-active hydration that enhances antioxidant activity and supports optimal cellular function. Redox-active hydration from ERW improves cellular water absorption, reduces free radicals, and balances oxidative stress critical for maintaining metabolic health and preventing chronic diseases.

Electrolyzed Reduced Water (ERW) Microclustering

Electrolyzed Reduced Water (ERW) features microclustered water molecules that enhance hydration efficiency and promote better nutrient absorption compared to the larger clusters found in hard water. The microclustering effect in ERW results from electrolysis, breaking down water into smaller, more bioavailable molecular groups that improve cellular hydration and detoxification processes.

Oxidation-Reduction Potential (ORP) Shift

Hard water typically exhibits a positive Oxidation-Reduction Potential (ORP) ranging from +200 to +400 mV, indicating an oxidizing environment, whereas Electrolyzed Reduced Water (ERW) shows a negative ORP often between -200 to -400 mV, reflecting a strong reducing environment rich in molecular hydrogen. This significant ORP shift in ERW enhances its antioxidant properties, which may contribute to reducing oxidative stress and improving cellular health compared to hard water.

Hydrogen-Rich Water Technology

Hydrogen-rich water generated through Electrolyzed Reduced Water (ERW) technology contains molecular hydrogen molecules that act as powerful antioxidants, effectively neutralizing harmful free radicals and reducing oxidative stress. Unlike hard water, which is high in calcium and magnesium ions causing mineral buildup and scaling, hydrogen-rich water provides enhanced hydration and potential health benefits by promoting cellular protection and reducing inflammation.

Silicate Stabilization Agents

Hard water contains natural silicate stabilization agents derived from dissolved minerals like calcium and magnesium silicates, which contribute to scale formation in pipes and appliances. Electrolyzed Reduced Water (ERW) typically lacks these silicate compounds, reducing scale buildup and improving water's ability to maintain silicate stability for industrial and cleaning applications.

Bicarbonate Buffering Capacity

Hard water contains high levels of bicarbonates, contributing to its strong buffering capacity, which helps maintain pH stability in various applications. Electrolyzed Reduced Water exhibits enhanced bicarbonate buffering capacity, improving its antioxidant properties and promoting better acid-base balance in biological systems.

Limescale Mitigation Nanocoatings

Electrolyzed Reduced Water (ERW) significantly reduces limescale buildup by altering water's mineral composition, preventing calcium and magnesium ions from crystallizing on surfaces, unlike hard water that promotes thick limescale deposits. Nanocoatings combined with ERW enhance limescale mitigation by creating durable, hydrophobic barriers on pipes and appliances, further inhibiting mineral adhesion and scaling.

Electrochemical Water Softening

Electrochemical water softening uses electric currents to reduce calcium and magnesium ions in hard water, producing electrolyzed reduced water with lower hardness and enhanced antioxidant properties. This process contrasts traditional methods by minimizing chemical additives and improving water quality through ion transformation and increased pH levels.

Hard Water vs Electrolyzed Reduced Water Infographic

industrydif.com

industrydif.com