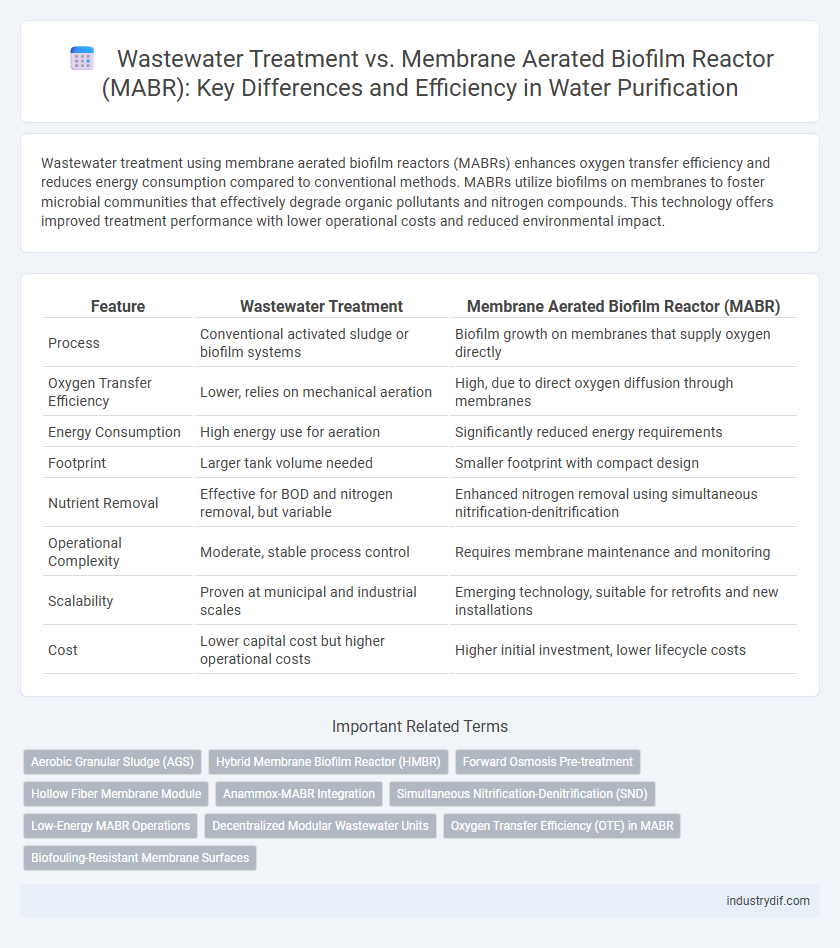

Wastewater treatment using membrane aerated biofilm reactors (MABRs) enhances oxygen transfer efficiency and reduces energy consumption compared to conventional methods. MABRs utilize biofilms on membranes to foster microbial communities that effectively degrade organic pollutants and nitrogen compounds. This technology offers improved treatment performance with lower operational costs and reduced environmental impact.

Table of Comparison

| Feature | Wastewater Treatment | Membrane Aerated Biofilm Reactor (MABR) |

|---|---|---|

| Process | Conventional activated sludge or biofilm systems | Biofilm growth on membranes that supply oxygen directly |

| Oxygen Transfer Efficiency | Lower, relies on mechanical aeration | High, due to direct oxygen diffusion through membranes |

| Energy Consumption | High energy use for aeration | Significantly reduced energy requirements |

| Footprint | Larger tank volume needed | Smaller footprint with compact design |

| Nutrient Removal | Effective for BOD and nitrogen removal, but variable | Enhanced nitrogen removal using simultaneous nitrification-denitrification |

| Operational Complexity | Moderate, stable process control | Requires membrane maintenance and monitoring |

| Scalability | Proven at municipal and industrial scales | Emerging technology, suitable for retrofits and new installations |

| Cost | Lower capital cost but higher operational costs | Higher initial investment, lower lifecycle costs |

Introduction to Wastewater Treatment Technologies

Wastewater treatment technologies encompass a range of processes designed to remove contaminants from sewage and industrial effluents, ensuring environmental protection and public health. Traditional methods include primary sedimentation, activated sludge, and trickling filters, which rely on physical, chemical, and biological mechanisms to degrade pollutants. Membrane Aerated Biofilm Reactor (MABR) technology combines biofilm processes with membrane aeration, enhancing oxygen transfer efficiency and reducing energy consumption compared to conventional activated sludge systems.

Overview of Membrane Aerated Biofilm Reactor (MABR)

Membrane Aerated Biofilm Reactor (MABR) is an advanced wastewater treatment technology that utilizes a gas-permeable membrane to deliver oxygen directly to the biofilm, enhancing microbial activity while reducing energy consumption. This system promotes simultaneous nitrification and denitrification within a single reactor, improving nitrogen removal efficiency compared to conventional aerobic treatment methods. MABR offers compact design benefits, lower operational costs, and increased treatment capacity, making it a sustainable alternative for municipal and industrial wastewater applications.

Key Components of Conventional Wastewater Treatment

Conventional wastewater treatment primarily relies on key components such as primary sedimentation tanks, activated sludge reactors, and secondary clarifiers to remove organic pollutants and suspended solids. These systems use aeration basins to supply oxygen to microbial communities that break down contaminants, followed by sludge settling processes to separate biomass from treated water. The integration of chemical dosing units and disinfection stages further ensures the removal of pathogens and nutrients before effluent discharge.

How MABR Technology Works

Membrane Aerated Biofilm Reactor (MABR) technology enhances wastewater treatment by integrating a gas-permeable membrane that supplies oxygen directly to the biofilm, optimizing microbial activity for nitrogen and organic matter removal. This system uses passive oxygen transfer through the membrane, reducing energy consumption compared to traditional aeration methods in conventional activated sludge processes. MABR's efficient oxygen delivery supports higher biomass density and improved treatment performance in a compact footprint, making it a sustainable solution for wastewater treatment facilities.

Efficiency Comparison: Traditional vs. MABR Systems

Traditional wastewater treatment systems rely heavily on activated sludge processes, which can be energy-intensive and less efficient in nutrient removal compared to Membrane Aerated Biofilm Reactors (MABRs). MABR technology enhances oxygen transfer efficiency by delivering air directly through membranes, resulting in up to 50% energy savings and improved nitrogen removal rates exceeding 70%. Studies indicate that MABRs maintain stable performance under variable loads and reduce greenhouse gas emissions, making them a superior option for sustainable wastewater treatment.

Cost Analysis: Initial Investment and Operating Expenses

Wastewater treatment using traditional methods typically incurs lower initial investment costs but often results in higher long-term operating expenses due to energy consumption and chemical usage. Membrane Aerated Biofilm Reactors (MABRs) require a higher upfront capital investment for advanced membrane technology and system integration, yet offer significant reductions in energy costs and improved operational efficiency. Cost analysis reveals that despite the elevated initial expenditure, MABRs can deliver lower total life-cycle expenses through reduced aeration energy demand and enhanced nutrient removal performance.

Environmental Impact Assessment

Wastewater treatment using conventional methods often results in higher energy consumption and greater greenhouse gas emissions compared to Membrane Aerated Biofilm Reactor (MABR) technology. MABR systems optimize oxygen transfer efficiency, reducing aeration energy by up to 50%, and significantly lower nitrous oxide emissions, a potent greenhouse gas. Environmental impact assessments reveal that MABR can achieve more sustainable wastewater treatment with decreased carbon footprint and enhanced nitrogen removal efficiency.

Applications in Municipal and Industrial Settings

Wastewater treatment in municipal and industrial settings commonly employs advanced technologies like Membrane Aerated Biofilm Reactors (MABRs), which enhance oxygen transfer efficiency and reduce energy consumption compared to conventional activated sludge systems. MABRs are particularly effective for removing nitrogen and organic contaminants in complex wastewater streams, improving effluent quality while minimizing sludge production. Their scalability and adaptability make them suitable for diverse applications, including municipal sewage treatment plants and industrial effluent management processes.

Challenges and Limitations of Each Method

Wastewater treatment faces challenges such as high energy consumption, sludge management, and limited removal efficiency for emerging contaminants. Membrane Aerated Biofilm Reactor (MABR) systems offer improved oxygen transfer and reduced energy use but are limited by membrane fouling, aeration control complexity, and higher initial capital costs. Both methods require ongoing maintenance and optimization to balance operational efficiency with environmental compliance.

Future Trends in Wastewater Treatment Innovation

Emerging trends in wastewater treatment emphasize the integration of Membrane Aerated Biofilm Reactors (MABRs) for enhanced energy efficiency and nitrogen removal compared to traditional activated sludge processes. Innovations focus on optimizing biofilm growth on membranes to reduce oxygen demand and operational costs while improving effluent quality. Future developments prioritize scalability, real-time monitoring with advanced sensors, and hybrid systems combining MABRs with other treatment technologies to meet stricter environmental regulations.

Related Important Terms

Aerobic Granular Sludge (AGS)

Aerobic Granular Sludge (AGS) in Wastewater Treatment enhances biomass retention and accelerates pollutant degradation compared to conventional Membrane Aerated Biofilm Reactor (MABR) systems, offering superior settling properties and nutrient removal efficiency. AGS technology facilitates simultaneous nitrification-denitrification and phosphorus removal within compact reactors, reducing footprint and operational costs in wastewater treatment plants.

Hybrid Membrane Biofilm Reactor (HMBR)

The Hybrid Membrane Biofilm Reactor (HMBR) integrates conventional activated sludge processes with membrane aerated biofilm technology, enhancing organic removal and nitrification efficiency in wastewater treatment. This hybrid system reduces energy consumption and sludge production while improving effluent quality compared to traditional wastewater treatment methods.

Forward Osmosis Pre-treatment

Forward osmosis pre-treatment enhances wastewater treatment efficiency by using a semi-permeable membrane to concentrate contaminants before the Membrane Aerated Biofilm Reactor (MABR) stage, improving nutrient removal and reducing membrane fouling. This integration optimizes biofilm activity and energy consumption, leading to higher treatment performance and sustainability in wastewater management.

Hollow Fiber Membrane Module

Hollow fiber membrane modules in Membrane Aerated Biofilm Reactors (MABRs) enhance wastewater treatment by providing increased surface area for biofilm growth and efficient oxygen transfer, leading to higher nitrogen removal rates compared to conventional activated sludge processes. Their compact design and energy-efficient aeration reduce operational costs while improving effluent quality and compliance with stringent discharge standards.

Anammox-MABR Integration

Anammox-MABR integration enhances wastewater treatment by combining anaerobic ammonium oxidation with membrane aerated biofilm reactors, resulting in higher nitrogen removal efficiency and reduced energy consumption. This synergy optimizes microbial activity on biofilms, enabling simultaneous nitrification and denitrification within a compact, low-oxygen environment.

Simultaneous Nitrification-Denitrification (SND)

Wastewater treatment utilizing Membrane Aerated Biofilm Reactors (MABRs) enhances Simultaneous Nitrification-Denitrification (SND) by providing optimal oxygen transfer and biofilm stability, leading to higher nitrogen removal efficiency compared to conventional activated sludge processes. MABRs enable controlled oxygen diffusion through membranes, promoting aerobic and anoxic zones within the biofilm that facilitate simultaneous nitrification and denitrification in a single reactor.

Low-Energy MABR Operations

Membrane Aerated Biofilm Reactors (MABR) offer low-energy wastewater treatment by utilizing a biofilm on gas-permeable membranes to efficiently deliver oxygen, significantly reducing aeration energy compared to conventional activated sludge processes. These systems enhance nitrogen removal and organic contaminant degradation with lower operational costs and reduced carbon footprint, making MABR technology a sustainable alternative for modern wastewater treatment facilities.

Decentralized Modular Wastewater Units

Decentralized modular wastewater units using Membrane Aerated Biofilm Reactor (MABR) technology offer enhanced energy efficiency and higher treatment performance compared to conventional wastewater treatment methods. These systems enable compact design, reduced footprint, and scalability, making them ideal for on-site or remote wastewater management with improved nutrient removal and lower operational costs.

Oxygen Transfer Efficiency (OTE) in MABR

Membrane Aerated Biofilm Reactors (MABRs) achieve significantly higher Oxygen Transfer Efficiency (OTE) compared to traditional wastewater treatment methods by delivering oxygen directly to biofilms through gas-permeable membranes, reducing energy consumption by up to 70%. Enhanced OTE in MABRs results in improved nitrification and organic matter removal, making them highly efficient for wastewater treatment with lower operational costs.

Biofouling-Resistant Membrane Surfaces

Biofouling-resistant membrane surfaces in Membrane Aerated Biofilm Reactors (MABRs) significantly reduce clogging and maintain high treatment efficiency compared to traditional wastewater treatment methods. Advanced coatings and surface modifications inhibit microbial attachment, enhancing membrane longevity and lowering operational costs in wastewater management systems.

Wastewater Treatment vs Membrane Aerated Biofilm Reactor Infographic

industrydif.com

industrydif.com