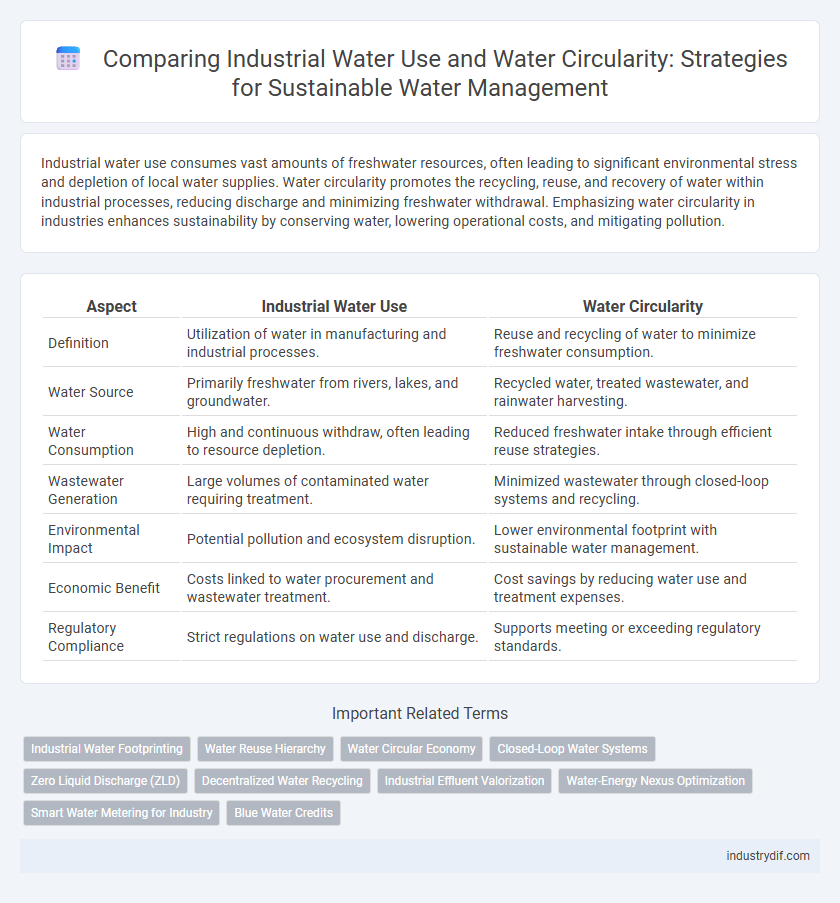

Industrial water use consumes vast amounts of freshwater resources, often leading to significant environmental stress and depletion of local water supplies. Water circularity promotes the recycling, reuse, and recovery of water within industrial processes, reducing discharge and minimizing freshwater withdrawal. Emphasizing water circularity in industries enhances sustainability by conserving water, lowering operational costs, and mitigating pollution.

Table of Comparison

| Aspect | Industrial Water Use | Water Circularity |

|---|---|---|

| Definition | Utilization of water in manufacturing and industrial processes. | Reuse and recycling of water to minimize freshwater consumption. |

| Water Source | Primarily freshwater from rivers, lakes, and groundwater. | Recycled water, treated wastewater, and rainwater harvesting. |

| Water Consumption | High and continuous withdraw, often leading to resource depletion. | Reduced freshwater intake through efficient reuse strategies. |

| Wastewater Generation | Large volumes of contaminated water requiring treatment. | Minimized wastewater through closed-loop systems and recycling. |

| Environmental Impact | Potential pollution and ecosystem disruption. | Lower environmental footprint with sustainable water management. |

| Economic Benefit | Costs linked to water procurement and wastewater treatment. | Cost savings by reducing water use and treatment expenses. |

| Regulatory Compliance | Strict regulations on water use and discharge. | Supports meeting or exceeding regulatory standards. |

Overview of Industrial Water Use

Industrial water use accounts for approximately 20% of global freshwater withdrawals, predominantly in sectors such as manufacturing, power generation, and mining. Industries typically consume large volumes of water for cooling, processing, and cleaning, often leading to significant water pollution challenges due to the discharge of untreated or inadequately treated wastewater. Enhancing water circularity through recycling and reuse within industrial processes can reduce freshwater dependency and mitigate environmental impacts.

Key Industries Consuming Water

Key industries consuming water include agriculture, textile, chemical, and energy sectors, accounting for over 70% of global industrial water use. Emphasizing water circularity in these industries involves implementing recycling, treatment, and reuse technologies to reduce freshwater withdrawal and minimize wastewater discharge. Adopting water circularity enhances sustainability by optimizing water management, lowering environmental impact, and ensuring long-term resource availability.

Water Consumption vs Water Withdrawal

Industrial water use distinguishes water withdrawal--the total volume extracted from sources--from water consumption, which denotes the portion permanently removed from the immediate environment through evaporation, incorporation, or contamination. Water circularity emphasizes reducing consumption by recycling and reusing withdrawn water within industrial processes to minimize freshwater inputs and environmental impact. Prioritizing water circularity enhances resource efficiency, decreases stress on natural water bodies, and supports sustainable industrial operations.

Impacts of Traditional Industrial Water Practices

Traditional industrial water use often leads to significant environmental degradation through excessive withdrawal of freshwater resources and the discharge of polluted effluents into ecosystems, causing water scarcity and habitat destruction. Inefficient water management practices result in high consumption rates and contamination, exacerbating water stress in industrial regions. Shifting towards water circularity reduces reliance on virgin water sources and minimizes wastewater generation, promoting sustainable water use and mitigating ecological impacts.

Introduction to Water Circularity

Industrial water use accounts for approximately 20% of global freshwater withdrawals, exerting significant pressure on finite water resources. Water circularity emphasizes the reuse, recycling, and recovery of water within industrial processes to minimize freshwater consumption and reduce wastewater discharge. Implementing water circularity strategies enhances sustainability, lowers operational costs, and mitigates environmental impacts by closing the industrial water loop.

Principles of Circular Water Management

Industrial water use demands efficient resource management to minimize freshwater withdrawal and wastewater discharge. Principles of circular water management emphasize reuse, recycling, and recovery of water within industrial processes to enhance sustainability and reduce environmental impact. Implementing closed-loop systems and advanced treatment technologies supports water circularity, promoting conservation and economic benefits in industrial sectors.

Technologies Enabling Water Circularity

Technologies enabling water circularity in industrial water use include advanced membrane filtration, biological treatment systems, and real-time water monitoring sensors that optimize reuse and reduce freshwater withdrawal. Industrial sectors leverage membrane bioreactors (MBRs) and reverse osmosis (RO) to achieve high-efficiency wastewater recycling, minimizing discharge and supporting water circularity principles. Integration of smart water management platforms facilitates data-driven decision-making for process water reuse, enhancing sustainability in industrial water usage.

Benefits of Adopting Water Circularity in Industry

Adopting water circularity in industry significantly reduces freshwater withdrawal by reusing treated wastewater, leading to decreased environmental strain and lower operational costs. Advanced recycling technologies improve water efficiency and minimize discharge pollution, supporting compliance with stringent environmental regulations. Enhanced water circularity also fosters sustainability by conserving natural resources and promoting corporate social responsibility within industrial sectors.

Barriers to Industrial Water Circularity

Industrial water use faces significant barriers to achieving water circularity, including high treatment costs, complex regulatory frameworks, and technological limitations in wastewater recycling. Many industries struggle with contamination challenges that require advanced purification processes before water reuse is feasible. Inadequate infrastructure and lack of industry-wide standards further restrict large-scale implementation of circular water practices in manufacturing and processing facilities.

Future Trends in Industrial Water Use and Circularity

Future trends in industrial water use emphasize reducing freshwater consumption through advanced water circularity practices such as wastewater recycling, zero liquid discharge systems, and real-time water quality monitoring. Industries increasingly adopt closed-loop water management to minimize environmental impact and comply with stringent regulatory frameworks while enhancing operational efficiency. Integration of digital technologies like AI and IoT facilitates optimized water allocation and predictive maintenance, driving sustainable industrial water use and circularity.

Related Important Terms

Industrial Water Footprinting

Industrial water use accounts for approximately 20% of global freshwater withdrawal, emphasizing the critical need for enhanced water circularity through advanced recycling and reuse technologies. Industrial water footprinting quantifies water consumption and pollution in production processes, enabling industries to implement efficient water management strategies and reduce environmental impact.

Water Reuse Hierarchy

The Water Reuse Hierarchy prioritizes direct industrial water reuse to minimize freshwater withdrawal and reduce wastewater discharge, promoting resource efficiency in industrial water use. Implementing hierarchy levels--from source reduction and on-site reuse to indirect reuse and eventual discharge--maximizes water circularity, driving sustainable industrial water management and conservation.

Water Circular Economy

Water circular economy promotes efficient industrial water use by emphasizing reuse, recycling, and recovery processes that reduce freshwater withdrawal and minimize wastewater discharge. Adopting closed-loop water systems and advanced treatment technologies enables industries to conserve resources, lower operational costs, and support sustainable water management.

Closed-Loop Water Systems

Closed-loop water systems in industrial water use significantly reduce freshwater withdrawal by recycling and reusing process water within production cycles, enhancing water circularity and minimizing environmental impact. Implementing advanced treatment technologies enables industries to achieve higher water recovery rates, lower wastewater discharge, and contribute to sustainable water resource management.

Zero Liquid Discharge (ZLD)

Industrial water use often involves high volumes of contaminated wastewater, making Zero Liquid Discharge (ZLD) a crucial technology for achieving water circularity by recovering and recycling nearly 100% of water within facilities. Implementing ZLD systems significantly reduces freshwater withdrawal and wastewater discharge, promoting sustainable industrial practices and conserving critical water resources.

Decentralized Water Recycling

Decentralized water recycling significantly reduces industrial water use by treating and reusing wastewater on-site, minimizing the demand for freshwater imports and lowering discharge volumes. This approach enhances water circularity by enabling continuous water reuse, reducing environmental impact, and supporting sustainable industrial operations.

Industrial Effluent Valorization

Industrial water use involves large volumes of freshwater intake and generates significant effluent, which can be valorized through advanced treatment technologies to recover valuable resources such as nutrients, energy, and clean water. Enhancing water circularity in industries reduces environmental discharge, lowers freshwater demand, and promotes sustainable resource management by converting wastewater into reusable inputs.

Water-Energy Nexus Optimization

Industrial water use accounts for approximately 20% of global freshwater withdrawal, demanding significant energy input for extraction, treatment, and distribution, which underscores the critical need for optimizing the water-energy nexus. Implementing water circularity practices, such as wastewater recycling and energy recovery from treatment processes, can substantially reduce both water consumption and energy footprint, enhancing sustainability and operational efficiency in industrial sectors.

Smart Water Metering for Industry

Smart water metering enhances industrial water use efficiency by providing real-time data on consumption patterns, enabling targeted reductions and leak detection. Integrating these meters into water circularity strategies supports sustainable resource management through precise monitoring and optimized recycling processes.

Blue Water Credits

Industrial water use significantly strains freshwater resources, with blue water withdrawals accounting for a large share of global consumption; Blue Water Credits promote water circularity by incentivizing efficient water reuse and reducing reliance on virgin blue water sources. These credits support sustainable water management practices, enhancing industrial water footprint reduction and contributing to the preservation of critical freshwater ecosystems.

Industrial Water Use vs Water Circularity Infographic

industrydif.com

industrydif.com