Water recycling involves treating wastewater to a level suitable for non-potable uses such as irrigation, industrial processes, or groundwater recharge, reducing demand on freshwater sources. Direct potable reuse bypasses environmental buffers by treating wastewater to meet drinking water standards before distribution, offering a sustainable solution to water scarcity. Advances in treatment technologies ensure safety and public health protection in both methods, making them critical components of modern water management strategies.

Table of Comparison

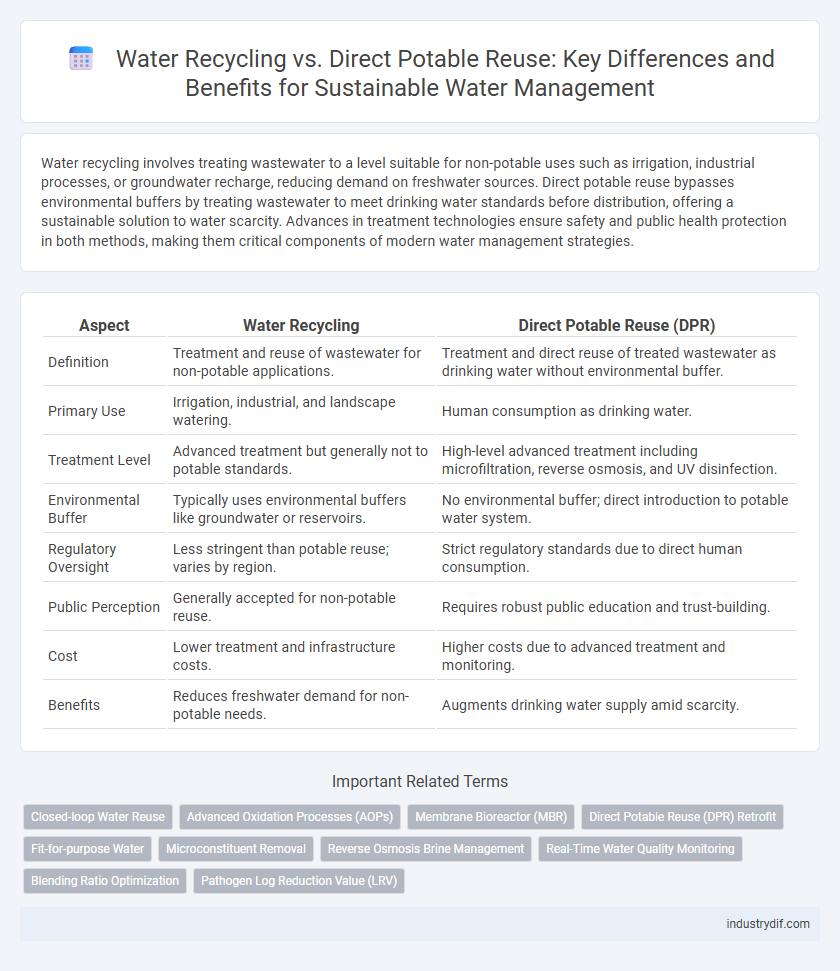

| Aspect | Water Recycling | Direct Potable Reuse (DPR) |

|---|---|---|

| Definition | Treatment and reuse of wastewater for non-potable applications. | Treatment and direct reuse of treated wastewater as drinking water without environmental buffer. |

| Primary Use | Irrigation, industrial, and landscape watering. | Human consumption as drinking water. |

| Treatment Level | Advanced treatment but generally not to potable standards. | High-level advanced treatment including microfiltration, reverse osmosis, and UV disinfection. |

| Environmental Buffer | Typically uses environmental buffers like groundwater or reservoirs. | No environmental buffer; direct introduction to potable water system. |

| Regulatory Oversight | Less stringent than potable reuse; varies by region. | Strict regulatory standards due to direct human consumption. |

| Public Perception | Generally accepted for non-potable reuse. | Requires robust public education and trust-building. |

| Cost | Lower treatment and infrastructure costs. | Higher costs due to advanced treatment and monitoring. |

| Benefits | Reduces freshwater demand for non-potable needs. | Augments drinking water supply amid scarcity. |

Introduction to Water Recycling and Direct Potable Reuse

Water recycling involves treating wastewater to remove contaminants so it can be reused for non-drinking purposes such as irrigation, industrial processes, and groundwater recharge. Direct potable reuse (DPR) is an advanced method where treated wastewater undergoes rigorous purification to meet drinking water standards and is then introduced directly into the potable water supply. Both approaches address water scarcity by maximizing resource efficiency, but DPR requires stringent monitoring and regulatory frameworks to ensure public health safety.

Key Definitions: Water Recycling vs Direct Potable Reuse

Water recycling involves treating wastewater to a level suitable for non-potable applications such as irrigation, industrial use, or groundwater recharge. Direct potable reuse (DPR) refers to the process of treating wastewater to meet or exceed drinking water standards and then delivering it directly into the potable water supply system. Both methods utilize advanced treatment technologies like membrane filtration, UV disinfection, and advanced oxidation to ensure safety and compliance with regulatory standards.

Process Overview: How Water Recycling Works

Water recycling involves collecting wastewater, treating it through physical, chemical, and biological processes to remove contaminants, and then reusing it for non-potable applications such as irrigation and industrial cooling. This multi-barrier treatment typically includes filtration, disinfection, and advanced purification methods like membrane filtration and UV irradiation to ensure safety. Direct potable reuse further advances the process by subjecting treated water to additional purification stages, making it safe for human consumption without blending with other water sources.

Understanding Direct Potable Reuse Systems

Direct potable reuse (DPR) systems treat wastewater through advanced filtration, disinfection, and membrane technologies to meet or exceed drinking water standards, enabling safe injection directly into the potable water supply. These systems rely on multiple barriers and continuous monitoring to ensure the elimination of contaminants, pathogens, and trace organic compounds. Unlike indirect reuse, DPR bypasses environmental buffers, offering an efficient, controlled, and resilient approach to augmenting water supplies in water-scarce regions.

Technical Differences Between Recycling and Potable Reuse

Water recycling involves treating wastewater to a level suitable for non-potable applications such as irrigation, industrial processes, or groundwater recharge, while direct potable reuse (DPR) advances the treatment to produce water safe for direct human consumption. DPR employs advanced purification technologies like microfiltration, reverse osmosis, ultraviolet disinfection, and advanced oxidation processes to remove contaminants, pathogens, and trace organic compounds to meet stringent drinking water standards. The key technical difference lies in treatment intensity and redundancy, with DPR requiring more rigorous multi-barrier treatment and real-time monitoring systems to ensure water safety for immediate consumption.

Water Quality and Safety Standards

Water recycling involves treating wastewater to meet rigorous safety standards for non-potable applications, ensuring contaminants are effectively removed through processes like membrane filtration and UV disinfection. Direct potable reuse (DPR) requires advanced treatment technologies, such as reverse osmosis and advanced oxidation, to surpass stringent regulatory water quality criteria set by agencies like the EPA to ensure safety for human consumption. Both systems incorporate multiple barriers and continuous monitoring to maintain water quality, but DPR demands higher purity levels due to its direct introduction into drinking water supplies.

Regulatory Frameworks and Compliance

Water recycling and direct potable reuse require stringent regulatory frameworks to ensure public health and safety. Regulatory agencies enforce compliance through standards that dictate treatment performance, monitoring protocols, and risk assessments tailored to recycled water or direct potable reuse systems. Compliance with these frameworks involves rigorous testing, transparent reporting, and ongoing evaluation to meet water quality parameters defined by environmental and health authorities.

Environmental and Economic Impacts

Water recycling reduces wastewater discharge and conserves freshwater sources, significantly lowering environmental pollution and energy consumption. Direct potable reuse offers greater economic benefits by cutting costs associated with extensive treatment and distribution infrastructure, though it requires advanced technology and stringent regulatory frameworks. Both approaches promote sustainable water management but differ in investment scale and ecological footprints.

Public Perception and Stakeholder Engagement

Public perception of water recycling versus direct potable reuse varies significantly, with many consumers expressing concerns about safety and quality in direct potable reuse systems due to limited familiarity and trust. Effective stakeholder engagement, including transparent communication and community involvement, is essential for addressing misconceptions and building confidence through education on advanced treatment technologies and regulatory standards. Collaboration among utilities, regulators, and the public fosters informed decision-making and enhances acceptance of sustainable water reuse practices.

Future Trends in Urban Water Sustainability

Water recycling technologies are advancing rapidly, enabling urban centers to reduce dependency on traditional freshwater sources and enhance resilience against climate change impacts. Direct potable reuse (DPR) is gaining traction due to its ability to safely convert treated wastewater into high-quality drinking water, supported by rigorous treatment processes and real-time monitoring systems. Future trends emphasize integrating smart water management systems, regulatory frameworks, and public acceptance strategies to drive sustainable urban water reuse solutions.

Related Important Terms

Closed-loop Water Reuse

Closed-loop water reuse systems prioritize recycling water within a contained network, minimizing waste and environmental discharge by treating and returning water for non-potable or potable applications onsite. Direct potable reuse involves advanced treatment processes that render recycled water safe for immediate consumption, offering a sustainable alternative to traditional water sources while ensuring stringent quality and safety standards.

Advanced Oxidation Processes (AOPs)

Advanced Oxidation Processes (AOPs) play a crucial role in both water recycling and Direct Potable Reuse (DPR) by effectively degrading organic contaminants and pathogens through hydroxyl radical generation. In DPR, AOPs are integral for ensuring treated water meets stringent potable water standards, while in water recycling, they enhance overall water quality for non-potable applications by targeting micropollutants and emerging contaminants.

Membrane Bioreactor (MBR)

Membrane Bioreactor (MBR) technology enhances water recycling by combining membrane filtration and biological treatment to produce high-quality effluent suitable for various non-potable applications, reducing environmental discharge. In direct potable reuse, MBR systems achieve advanced contaminant removal and microbial safety, enabling treated water to meet stringent drinking water standards without conventional groundwater recharge.

Direct Potable Reuse (DPR) Retrofit

Direct Potable Reuse (DPR) retrofit systems treat wastewater to meet stringent drinking water standards, enabling safe, immediate integration into potable water supplies and significantly reducing reliance on surface and groundwater sources. Advances in membrane filtration, ultraviolet disinfection, and real-time monitoring technologies ensure DPR retrofit facilities provide high-quality, pathogen-free water that supports sustainable urban water management and drought resilience.

Fit-for-purpose Water

Fit-for-purpose water strategies optimize water recycling by aligning water quality with specific end uses, reducing treatment costs and environmental impact compared to Direct Potable Reuse (DPR), which requires advanced purification for safe human consumption. By tailoring reclaimed water applications--such as irrigation, industrial processes, or groundwater recharge--fit-for-purpose approaches enhance resource efficiency while maintaining public health and regulatory compliance.

Microconstituent Removal

Water recycling systems employ advanced treatment technologies such as membrane filtration, advanced oxidation, and activated carbon to effectively remove microconstituents including pharmaceuticals, personal care products, and endocrine-disrupting compounds. Direct potable reuse incorporates multiple barriers and real-time monitoring to ensure microconstituent levels meet stringent safety standards, enabling safe reintroduction of treated water into drinking water supplies.

Reverse Osmosis Brine Management

Reverse osmosis brine management in water recycling involves advanced treatment techniques to minimize environmental discharge, while direct potable reuse integrates brine concentrate treatment to ensure the reclaimed water meets stringent potable standards. Effective brine management reduces salinity and contaminants, optimizing resource recovery and protecting ecosystems from hypersaline effluents.

Real-Time Water Quality Monitoring

Real-time water quality monitoring enhances water recycling by continuously detecting contaminants, ensuring safe treatment processes before reuse in irrigation or industrial applications. Direct potable reuse systems rely heavily on advanced sensor networks to immediately identify and mitigate pollutants, guaranteeing compliance with stringent drinking water standards for public health protection.

Blending Ratio Optimization

Blending ratio optimization in water recycling versus direct potable reuse enhances water quality by precisely balancing reclaimed water with treated potable sources to meet safety standards while maximizing resource efficiency. Advanced treatment technologies and real-time monitoring enable dynamic adjustment of blending ratios, ensuring stable water chemistry and public health protection in potable reuse systems.

Pathogen Log Reduction Value (LRV)

Water recycling systems typically achieve a Pathogen Log Reduction Value (LRV) between 6 to 9, effectively reducing viruses, bacteria, and protozoa to safe levels before environmental discharge or non-potable reuse. Direct potable reuse demands higher treatment stringency, often targeting LRVs exceeding 10 to ensure complete pathogen removal, enabling safe consumption without environmental buffering.

Water Recycling vs Direct Potable Reuse Infographic

industrydif.com

industrydif.com